BEFORE PROGRAMMING, CHECK...

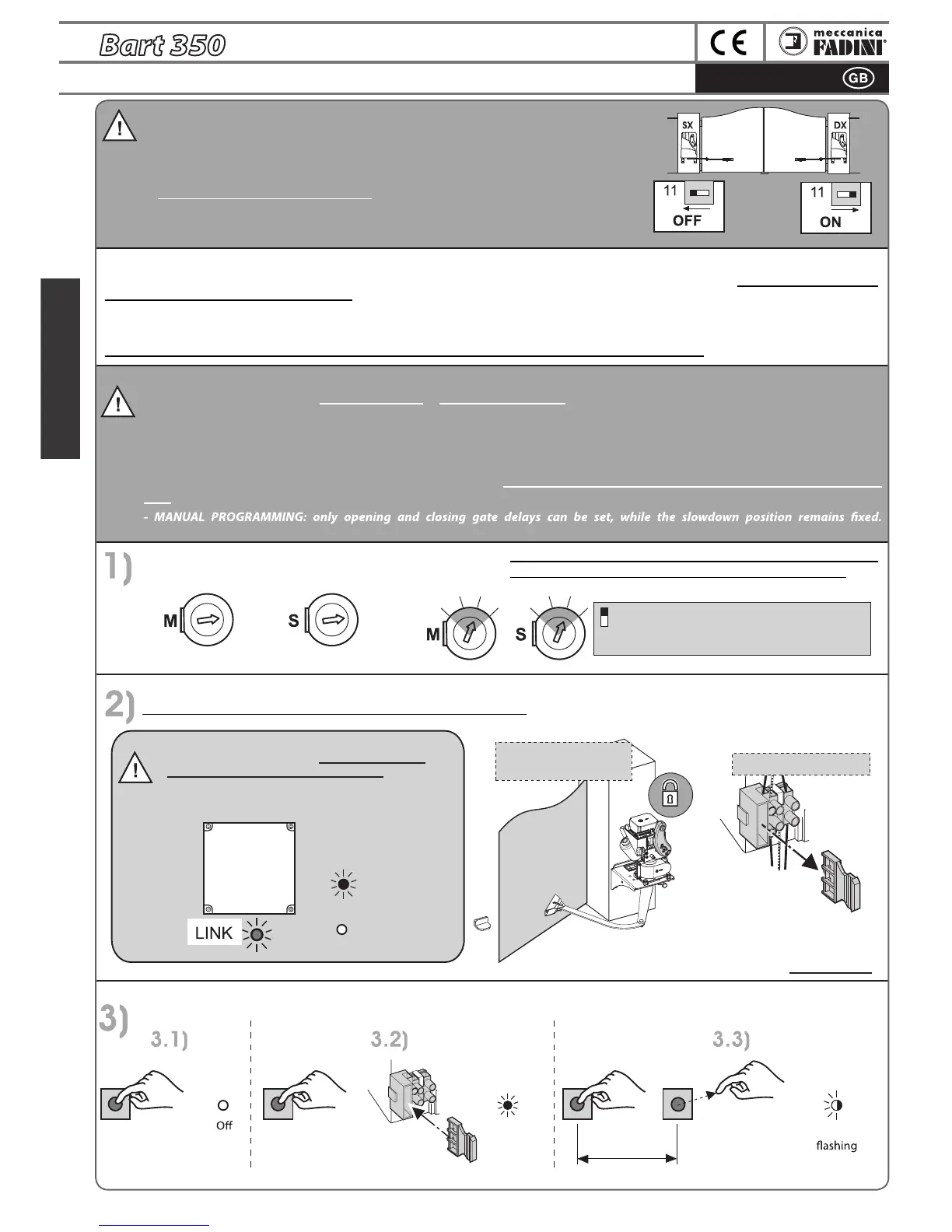

1) Correctly select Dip 11 on Elpro 35M for Bart 350 Master installation on the Right

(DX) or on the Left (Sx), as seen from inside.

2) Adjust the opening gate stops (pg.10) or enable limit switches (pg.11).

3) All GREEN LEDs MUST ALWAYS BE ON, otherwise check all NC safety contacts.

4) Check if the LINK LEDS in Elpro 35M and Elpro 35S are on, otherwise verify connection

to terminals 15-16-17-18.

IMPORTANT:

ELPRO 35M has the function of self-programming or manual programming:

- SELF-PROGRAMMING:

Recommended for systems with single gates (in this case, bridge terminals A-C and B-D), or for gates without gate overlap. The entire

opening and closing of one or both one gates, including slowdown before limit switch end stops, is left to the electronic board. This

operation is performed only with one pulse, and the programmer manages all gate movements.

Please note: Self-programming is recommended for gates which do not require an opening delay or are not equipped with an electric

lock.

Recommended for gates which overlap or have an electric lock on Bart 350 Master.

NOTE:

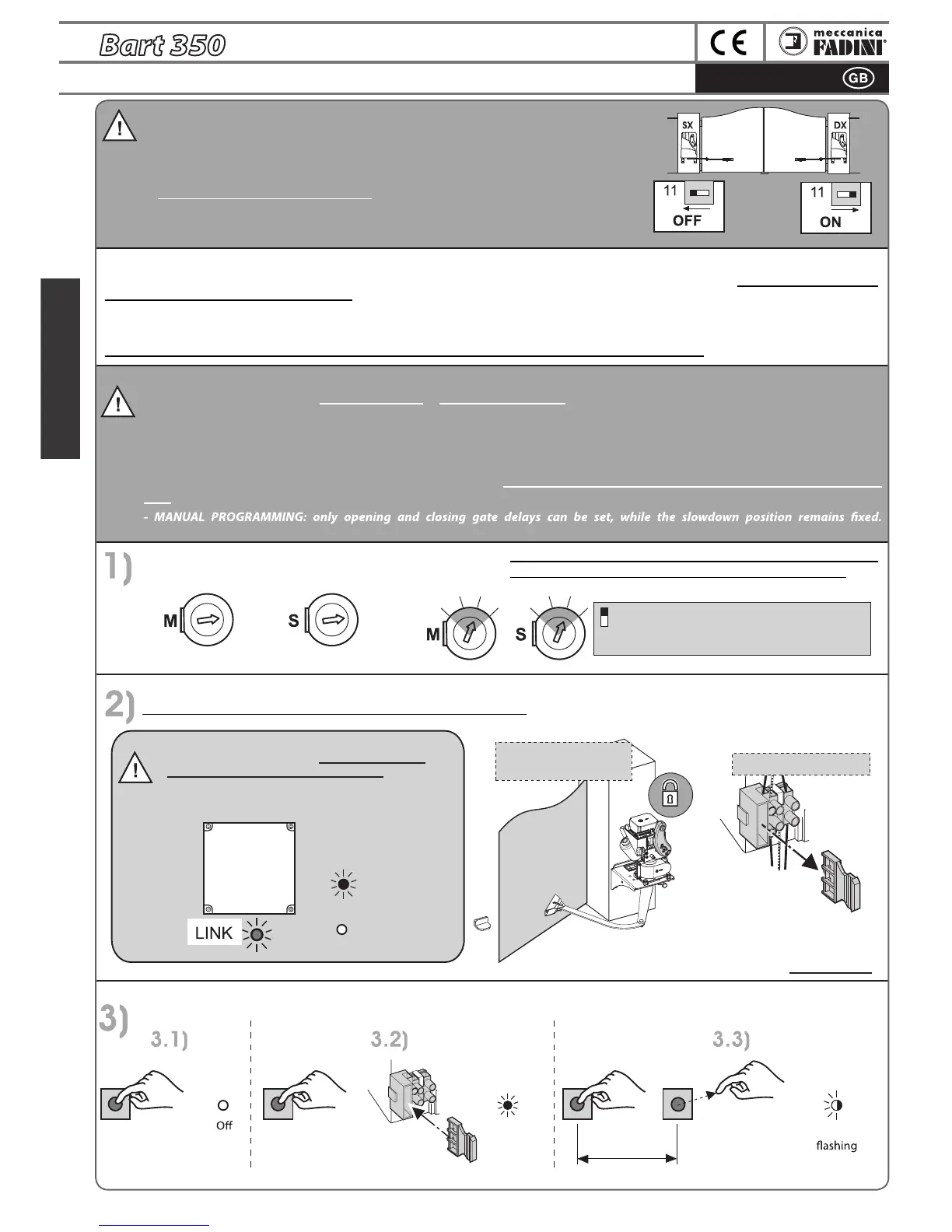

When mains power is present, all green LEDs on the

Elpro 35M and Elpro 35S must always be on.

If the green LEDs are not all on, check each electrical

connection before continuing with programming.

General information on programming:

- Any time a change is made to the gate stop position,limit switch cam, control board or to any of its component, you must reprogram gate

opening and closing with the same procedure.

- Even in the absence of mains power, programming is always stored. During the rst cycle after a black-out, the Bart will automatically search

for the rst end stop or limit switch at slow speed.

- During all programming phases, all control and safety accessories are deactivated. The utmost care is therefore recommended.

ONLY STOP CONTACTS 3-6 AND RADIO CONTACT 3-7 ARE ENABLED ONLY FOR MANUAL PROGRAMMING PULSES

IMPORTANT: adjust the torque trimmer according to th

e

type of material and inertia of the gate...

Lock the gate: pg.38 “Operations for restoring gate locking”.

Remove the power fuse on Bart 350 Master and power the system...

...low torque (maximum position three) is recommended for

light or deformable gates (in aluminium, wood, PVC, etc.)

ON: Decreases sensitivity on closing gate stop, to

prevent the gate travel from being reversed too

easily in case of incorrect installations.

min

LP LP

LP

min

min

GREEN LEDs

on

Bart 350 MASTER

Bart 350 SLAVE

Bart 350 MASTER

RED LEDs

o

min

max

On

slow

4-5 sec

max

maxmax

6

MASTER

SLAVE

Bart 350 Master locked

Bart 350 Slave locked

Remove the power

fuse present only on

the

Bart 350 Master.

with the programming button pressed, insert the line fuse, after 4/5 seconds, release the programming button: the LP LED will

remain on, conrming that programming is in progress

ELPRO 35M

Loading...

Loading...