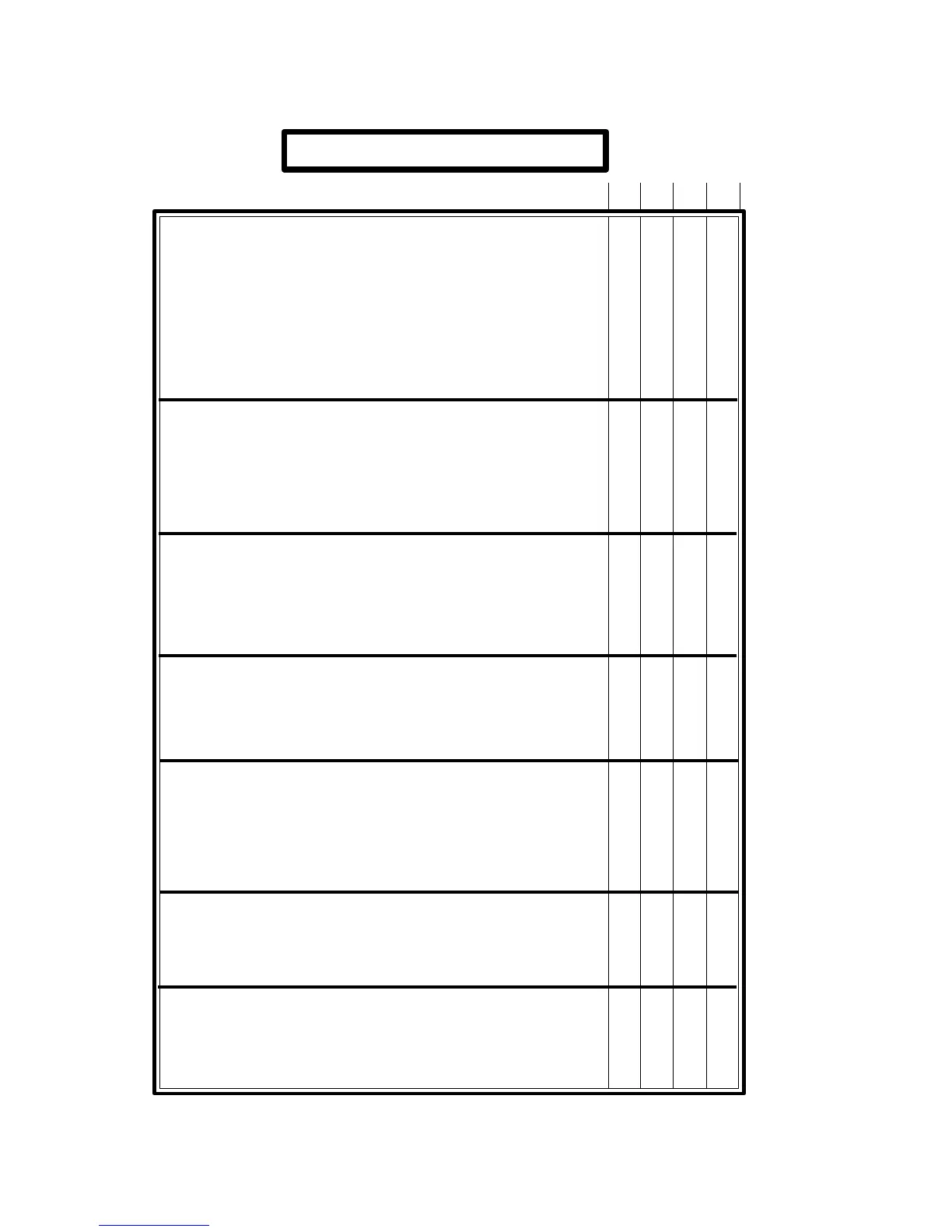

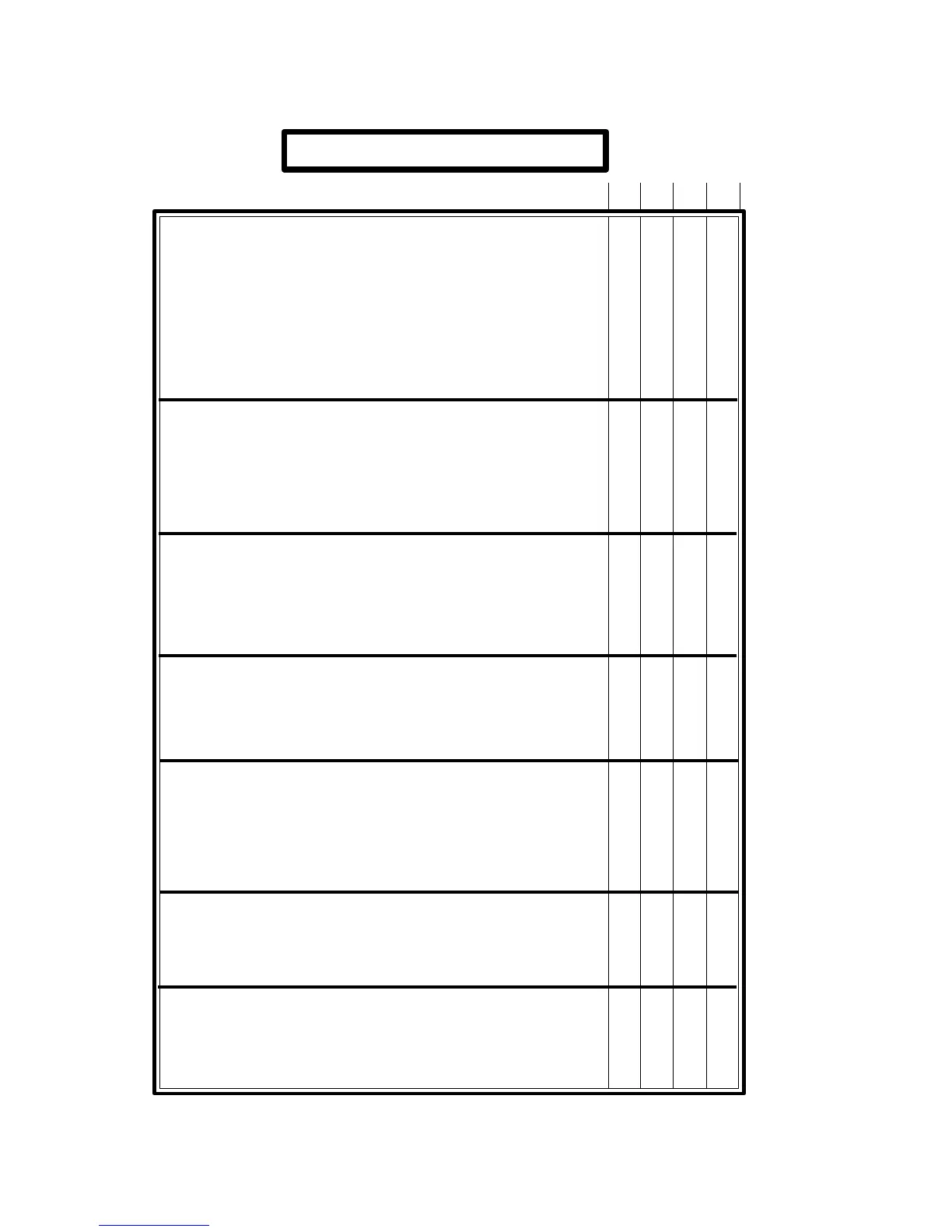

TECHNICAL DESCRIPTION

GP M MG MS

INPUTS/OUTPUTS

Feedback inputs. ........................................................................................ 6 6 6 6

Linear axes ........................................................................... 4 4 4 5

Rotary axes........................................................................... 2 2 2 2

Spindle encoder.................................................................... 1 1 1 1

Electronic handwheels ......................................................... 1 1 1 1

Probe input ............................................................................................. x x x x

Square-wave feedback signal multiplying factor, x2/x4 ........................... x x x x

Sine-wave feedback signal multiplying factor, x2/x4/10/x20 ................... x x x x

Maximum counting resolution 0.001mm/0.001°/0.0001inch.................... x x x x

Analog outputs (±10V) for axis servo drives ............................................ 4 4 4 5

Spindle analog output (±10V) ................................................................... 1 1 1 1

AXIS CONTROL

Axes involved in linear interpolations....................................................... 3 3 3 3

Axes involved in circular interpolations.................................................... 2 2 2 2

Helical interpolation .................................................................................. x x x x

Electronic threading .................................................................................. x x x

Spindle control .......................................................................................... x x x x

Software travel limits ................................................................................ x x x x

Spindle orientation .................................................................................... x x x x

Management of non-servo-controlled Open-Loop motor ......................... x

PROGRAMMING

Part Zero preset by user............................................................................. x x x x

Absolute/incremental programming .......................................................... x x x x

Programming in cartesian coordinates ...................................................... x x x x

Programming in polar coordinates ............................................................ x x x x

Programming in cylindrical coordinates (radius, angle, axis) ................... x x x x

Programming by angle and cartesian coordinate....................................... x x x x

COMPENSATION

Tool radius compensation ......................................................................... x x x

Tool length compensation ......................................................................... x x x x

Leadscrew backlash compensation............................................................ x x x x

Leadscrew error compensation.................................................................. x x x x

Cross compensation (beam sag) ................................................................ x x x x

DISPLAY

CNC text in Spanish, English, French, German and Italian ...................... x x x x

Display of execution time.......................................................................... x x x x

Piece counter ............................................................................................. x x x x

Graphic movement display and part simulation ........................................ x x

Tool base position display ......................................................................... x x x x

Tool tip position display............................................................................ x x x x

Geometric programming aide.................................................................... x x x x

COMMUNICATION WITH OTHER DEVICES

Communication vía RS232C ..................................................................... x x x x

Communication via DNC .......................................................................... x x x x

Communication via RS485 (FAGOR LAN) ............................................. x x x x

ISO program loading from peripherals...................................................... x x x x

OTHERS

Parametric programming ........................................................................... x x x x

Model digitizing ........................................................................................ x x x x

Possibility of an integrated PLC ................................................................ x x x x

Sheetmetal tracing on LASER machines................................................... x

Jig Grinder ............................................................................................. x

Loading...

Loading...