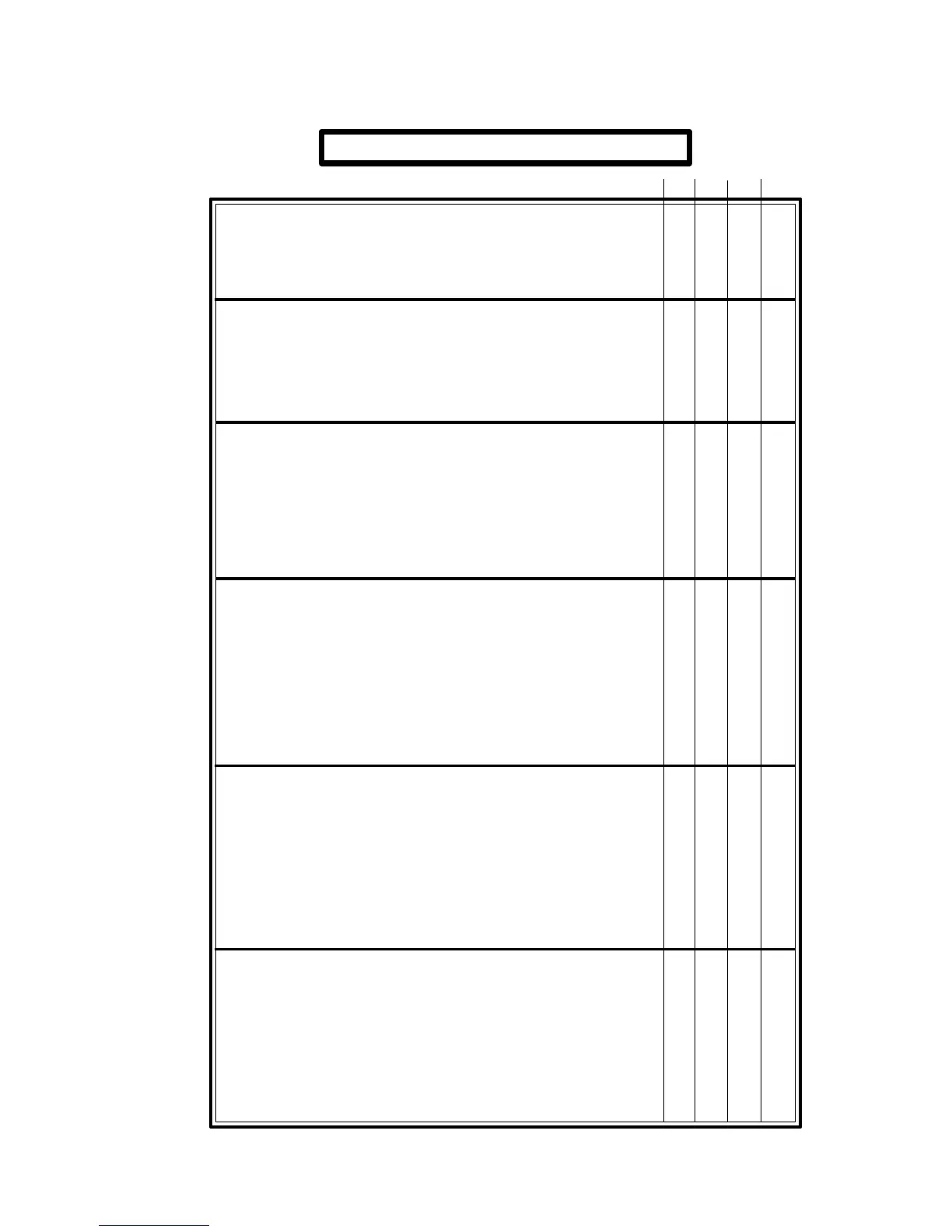

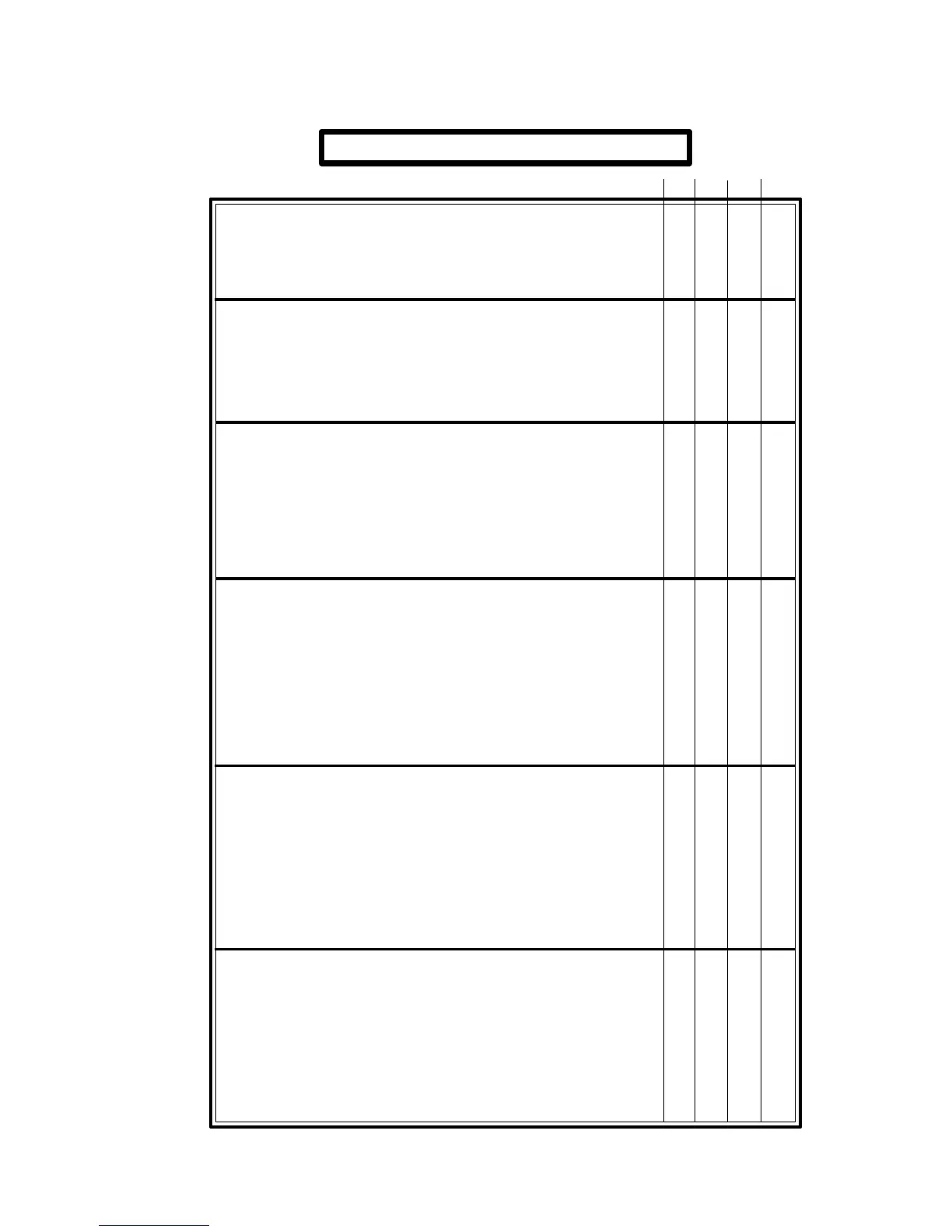

PREPARATORY FUNCTIONS

GP M MG MS

AXES AND COORDINATE SYSTEMS

XY (G17) plane selection ........................................................................... x x x x

XZ and YZ plane selection (G18,G19) ...................................................... x x x x

Part measuring units. Millimeters or inches (G70,G71) ............................. x x x x

Absolute/incremental programming (G90,G91) ........................................ x x x x

Independent axis (G65) .............................................................................. x x x x

REFERENCE SYSTEMS

Machine reference (home) search (G74) .................................................... x x x x

Coordinate preset (G92) ............................................................................. x x x x

Zero offsets (G53...G59) ............................................................................ x x x x

Polar origin preset (G93) ............................................................................ x x x x

Store current part zero (G31)...................................................................... x x x x

Recover stored part zero (G32) ................................................................. x x x x

PREPARATORY FUNCTIONS

Feedrate F .............................................................................................. x x x x

Feedrate in mm/min. or inches/minute (G94) ............................................ x x x x

Feedrate in mm/revolution or inches/revolution (G95) .............................. x x x x

Constant surface speed (G96)..................................................................... x x x x

Constant tool center speed (G97) ............................................................... x x x x

Programmable feedrate override (G49)...................................................... x x x x

Spindle speed (S)........................................................................................ x x x x

S value limit (G92) ..................................................................................... x x x x

Tool and tool offset selection (T) ............................................................... x x x x

AUXILIARY FUNCTIONS

Program stop (M00) ................................................................................... x x x x

Conditional program stop (M01)................................................................ x x x x

End of program (M02) ............................................................................... x x x x

End of program with return to first block (M30) ....................................... x x x x

Clockwise spindle start (M03).................................................................... x x x x

Counter-clockwise spindle start (M04) ...................................................... x x x x

Spindle stop (M05) ..................................................................................... x x x x

Tool change in machining centers (M06)................................................... x x x x

Spindle orientation (M19) .......................................................................... x x x x

Spindle speed range change (M41, M42, M43, M44)................................ x x x x

Functions associated with pallets (M22, M23, M24, M25)........................ x x x

PATH CONTROL

Rapid traverse (G00) ................................................................................x x x x

Linear interpolation (G01)........................................................................x x x x

Circular interpolation (G02,G03) .............................................................x x x x

Circular interpolation with absolute center coordinates (G06).................x x x x

Circular path tangent to previous path (G08) ...........................................x x x x

Arc defined by three points (G09)............................................................x x x x

Tangential entry at beginning of a machining operation (G37) ..............x x x x

Tangential exit at the end of a machining operation (G38) ......................x x x x

Controlled radius blend (G36)..................................................................x x x x

Chamfer (G39) .........................................................................................x x x x

Electronic threading (G33) ......................................................................... x x x

ADDITIONAL PREPARATORY FUNCTIONS

Dwell (G04 K)..........................................................................................x x x x

Round and square corner (G05, G07) ......................................................x x x x

Mirror image (G10,G11,G12) ..................................................................x x x x

Mirror image along the Z axis (G13) .......................................................x x x x

Scaling factor (G72) .................................................................................x x x x

Pattern rotation (G73)...............................................................................x x x x

Slaving/unslaving of axes (G77, G78) .....................................................x x x x

Single block treatment (G47, G48) ..........................................................x x x x

User error display (G30)...........................................................................x x x x

Automatic block generation (G76) ............................................................. x

Communication with FAGOR Local Area Network (G52)......................x x x x

Loading...

Loading...