17 18

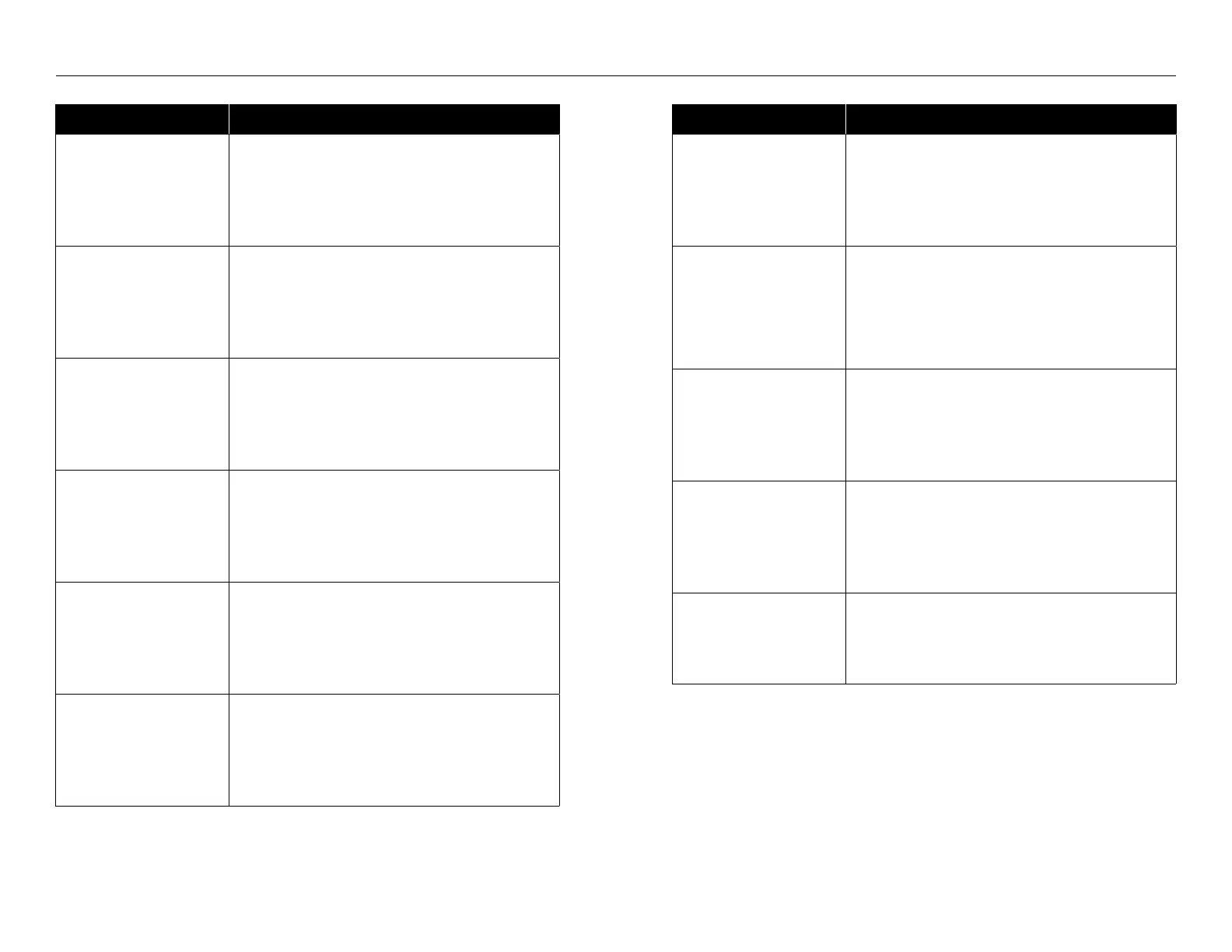

Troubleshooting Troubleshooting (continued)

Symptom Remedy

Motor turns and bit engages,

but screw does not insert or

falls to the side when tool is

raised

•

Check that motor reversing switch is in forward position.

•

Check Depth Control screw setting as it may be too long.

Screw inserts but does not go

in all the way

•

Confirm the bit is the correct length for the attachment.

•

Check to be sure that collars on the depth control/nose

pieces screws are seated correctly (see Set Up,

Depth Control Adjustment).

Screw strip falls forward out

of belt guide when tool is

raised into position

•

Turn orange knob attached to the front of belt guide

to increase tension.

Screw does not countersink

properly

•

Turn countersink adjustment ring until the proper

countersink is achieved.

•

Check bit to be sure it is the right type and length.

Screw tip drags on surface

before installation of screw

•

Screw tip is likely beyond the outside of the Depth

Control. Adjust Depth Control until screw tip protrudes

halfway into Depth Control Throat.

First few screws advance then

the belt stops moving

•

Loosen tension control on the belt guide to allow

movement.

•

Check gear wheel movement as described under

Cleaning and Repair.

Call 800·518·3569 or access fastenmaster.com for a technical specialist

if assistance is needed

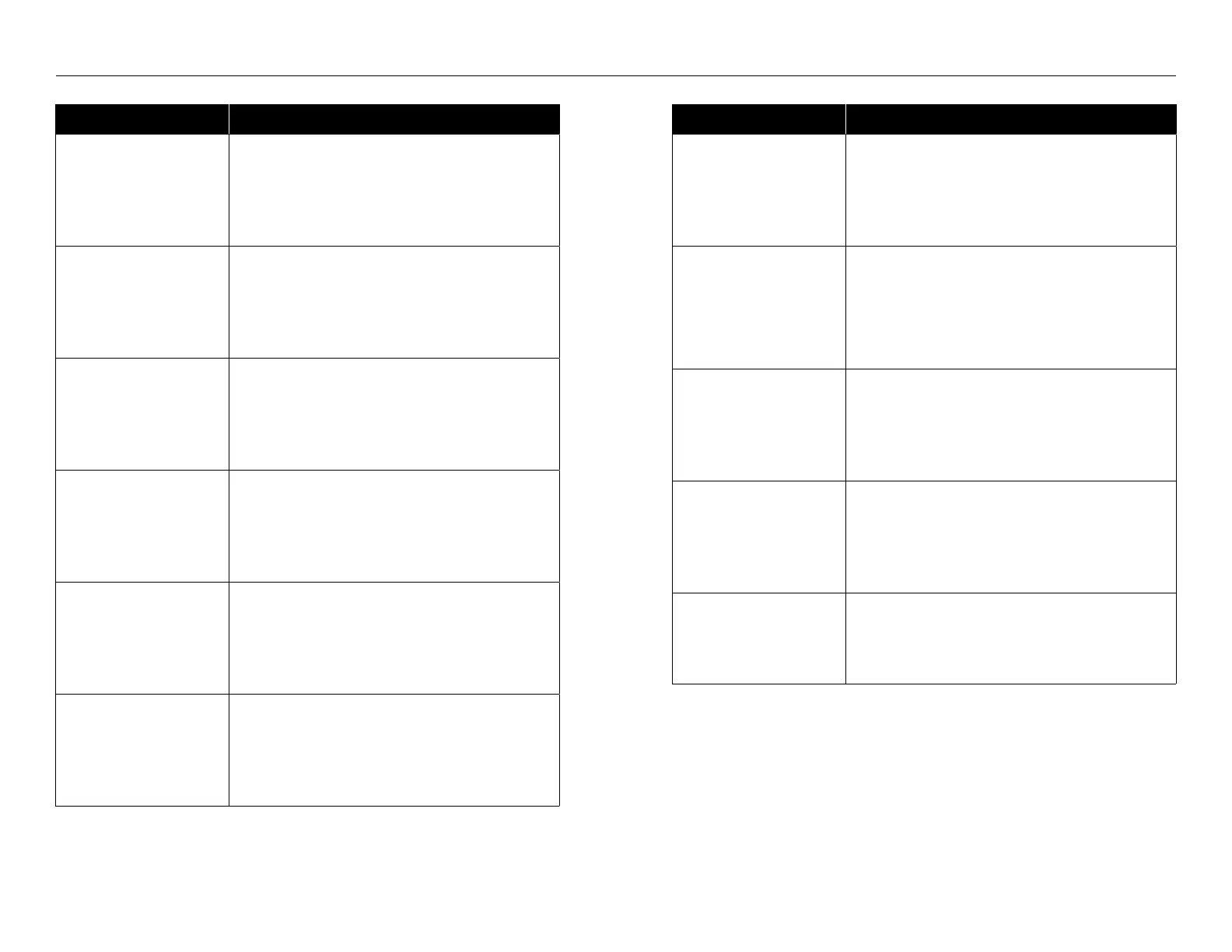

Symptom Remedy

Gliding piece will not retract

fully into housing on down-

stroke

•

Check that screws holding Depth Control in place are

fully seated into cut outs.

Gliding piece jams or is

difficult to move in the

housing.

•

Check first that there are no burrs on the front of the

housing that are interfering with the movement of the

gliding piece.

•

Check the width of the housing opening to ensure that

a bump or blow from something else has not forced the

front of the housing inward.

Screw is inserted only part

way before bit tip starts to

spin in recess.

•

Maintain constant downward pressure while screw is

being inserted. Too little or inconsistent pressure on

down-stroke will cause bit tip to lose full contact with

screw recess and potentially strip out recess.

Jammed fastener

•

Stop motor.

•

Pull screws completely through Gliding Piece.

Reinsert in belt guide and gliding piece.

•

To avoid jamming, be sure motor is running before

down stroke begins.

Screw becomes jammed in

Depth Control, gliding piece

or housing

•

Remove the fastener and test the tool.

Most of time the jam will cause no damage.

Loading...

Loading...