7 8

Setup and Adjustment Setup and Adjustment (continued)

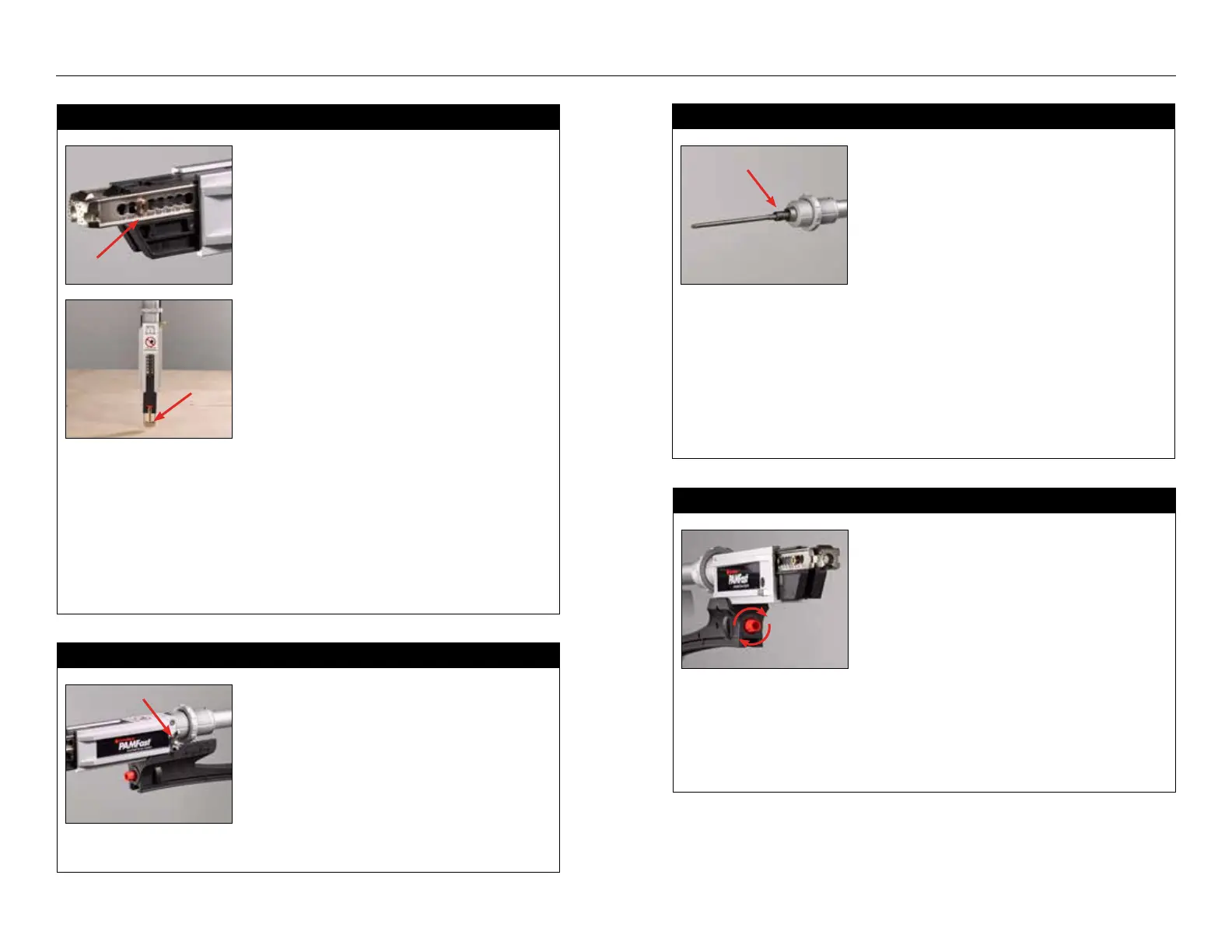

3) Belt Guide Adjustment

Belt tension on the PAMFast AutoFeed

tool is preset for 1

3

⁄4" fasteners. Use

of alternate size fasteners may require

adjustment of the belt tension.

Turn the red Tension Knob clockwise

to increase belt tension, or counter-

clockwise to reduce belt tension.(Fig 3a).

I Do not overtighten This will prevent the collated screw

strip from properly feeding through the belt guide. Proper tension

prevents excessive slack in the collated strip and ensures precise

advancement of the strip between drives.

Fig. 3a

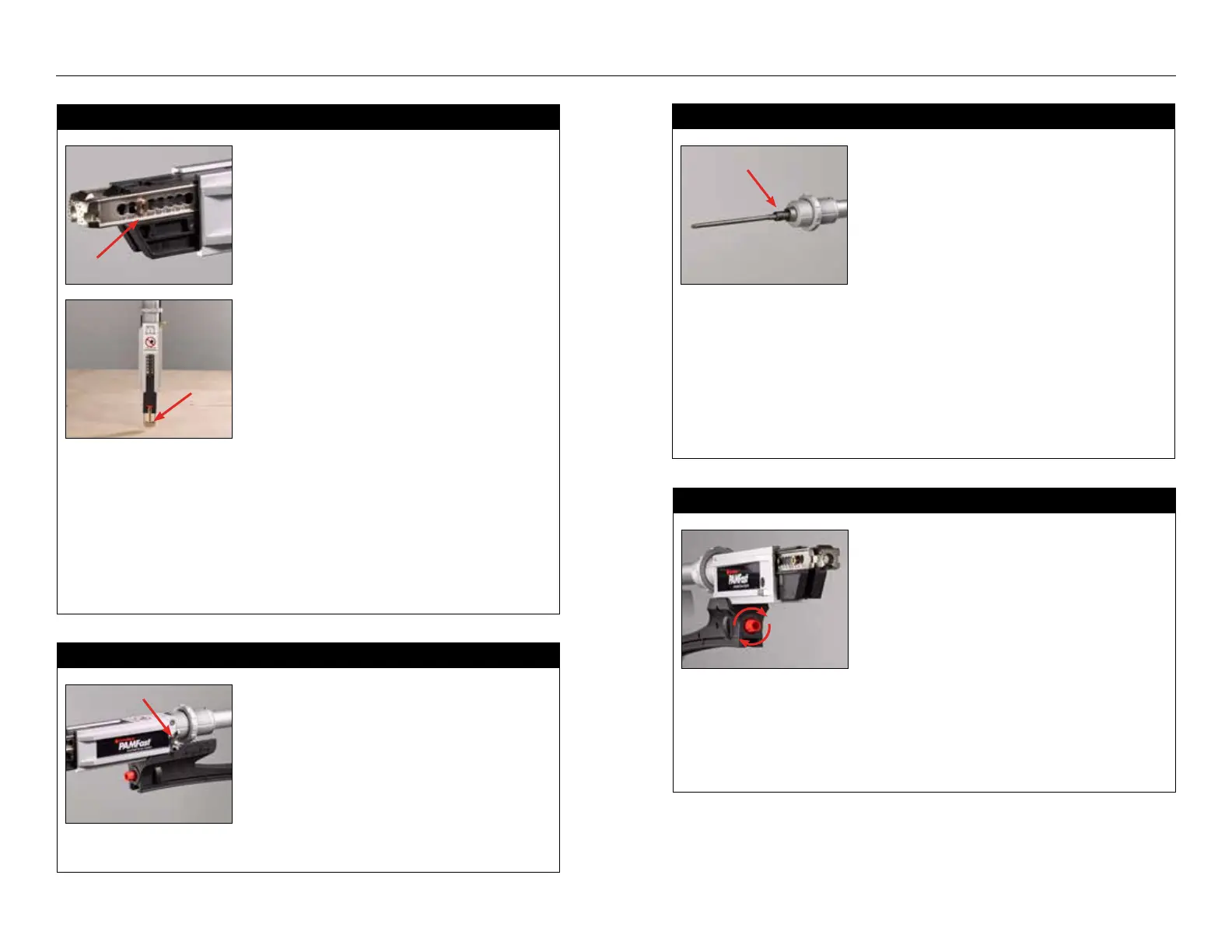

1) Screw Size Adjustment for Depth Control

Start by adjusting the PAMFast AutoFeed

attachment to accommodate the correct

screw length. The screw length is always

displayed on the side of the box of your

genuine PAMFast collated screws.

Loosen the shoulder screws on both sides

of the Depth Control and slide it to the

appropriate setting using the numbers

stamped on the Depth Control (Fig 1a).

When appropriately adjusted, the tip

of the fastener will be approximately

1

⁄

8

"

inside the face of the nose piece (Fig 1b).

I Note that the screws holding the Depth Control/

Nosepiece have collars so be sure that the collars of the

screws sit down in the cutouts of the Depth Control. If they

are not fully recessed, the gliding piece will not go back into

the housing fully and screw will not countersink.

2) Bit Replacement

For smooth operation and to reduce

cam-out, FastenMaster recommends

replacing drive bits after every

1,000 screws.

• Loosen the Wing Nut on the side

of the attachment assembly (Fig 2a).

2) Bit Replacement (continued)

• Remove the attachment assembly

to reveal the bit (Fig. 2b).

• Depress the lock collar and remove

the bit. After inserting the new bit,

release the collar to lock the bit

into place.

I Use only genuine PAMFast bits. Every tool comes

with one PAMDrive bit installed on tool. Additional bits such

as Phillips and Torx may be purchased.

• Bit should be approximately the same length as housing.

• Ensure bit type (Phillips, Torx or PAMDrive) matches

screw recess.

Fig. 1a

Fig. 1b

Fig. 2a

Fig. 2b

Loading...

Loading...