4

Mounting the PMA

4. Lay packaged pump on a at, open surface and

remove the package.

5. Flatten pump packaging and lay the PMA on the

end of the pump in preparation for mounting.

6. The PMA mounting hardware kit (# 152350902)

is attached to the PMA packaging. It contains

a gasket, a tube of grease, and four 5 / 16" cap

screws with lockwashers.

7. Remove the two packaging ends and the

protective sleeve from the PMA.

8. Apply grease provided to the inside wall of the

pump motor electrical connector, and the rubber of

the lead assembly connector.

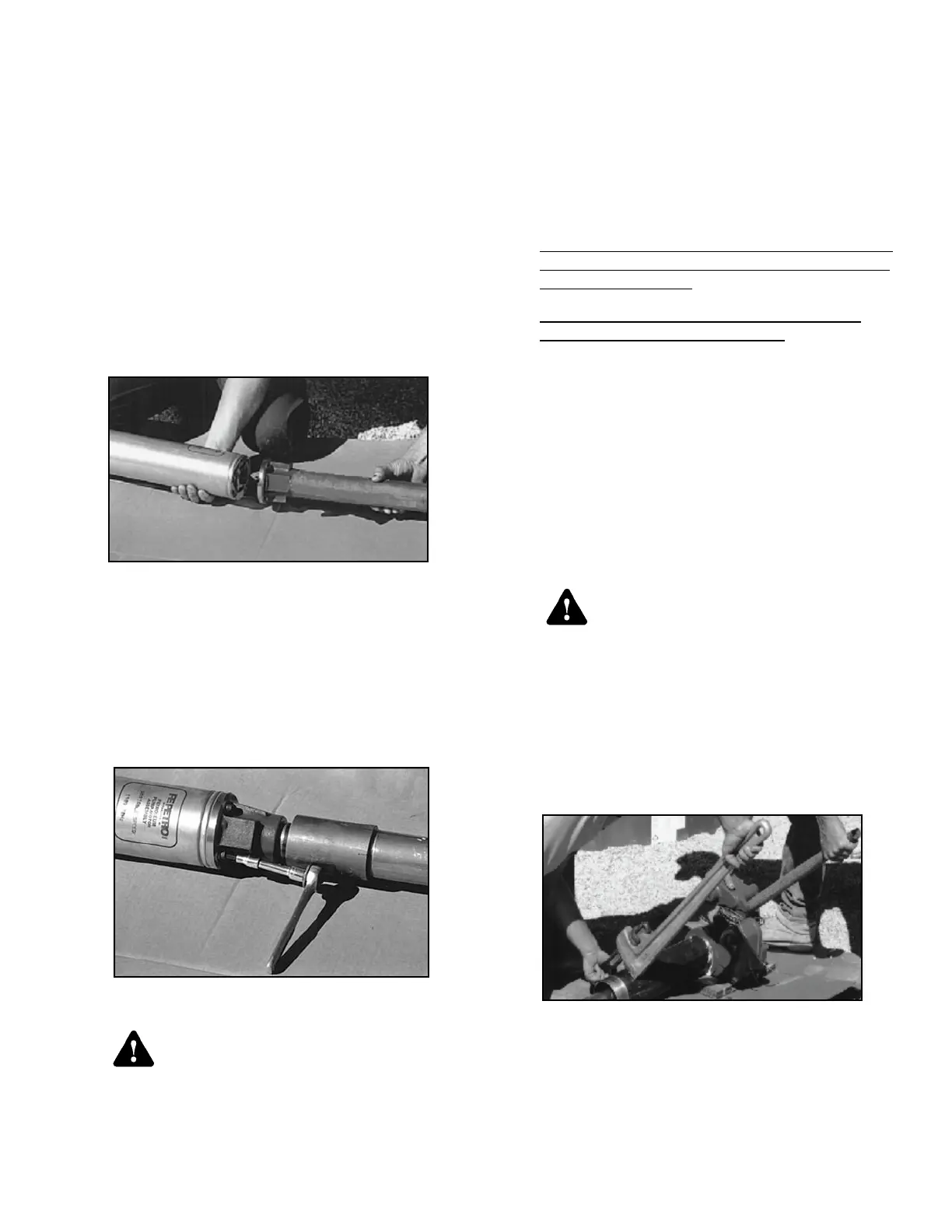

9. Place the gasket on the end of the PMA, aligning

locating pin and bolt holes (Figure 1).

Figure 1: Aligning Pins

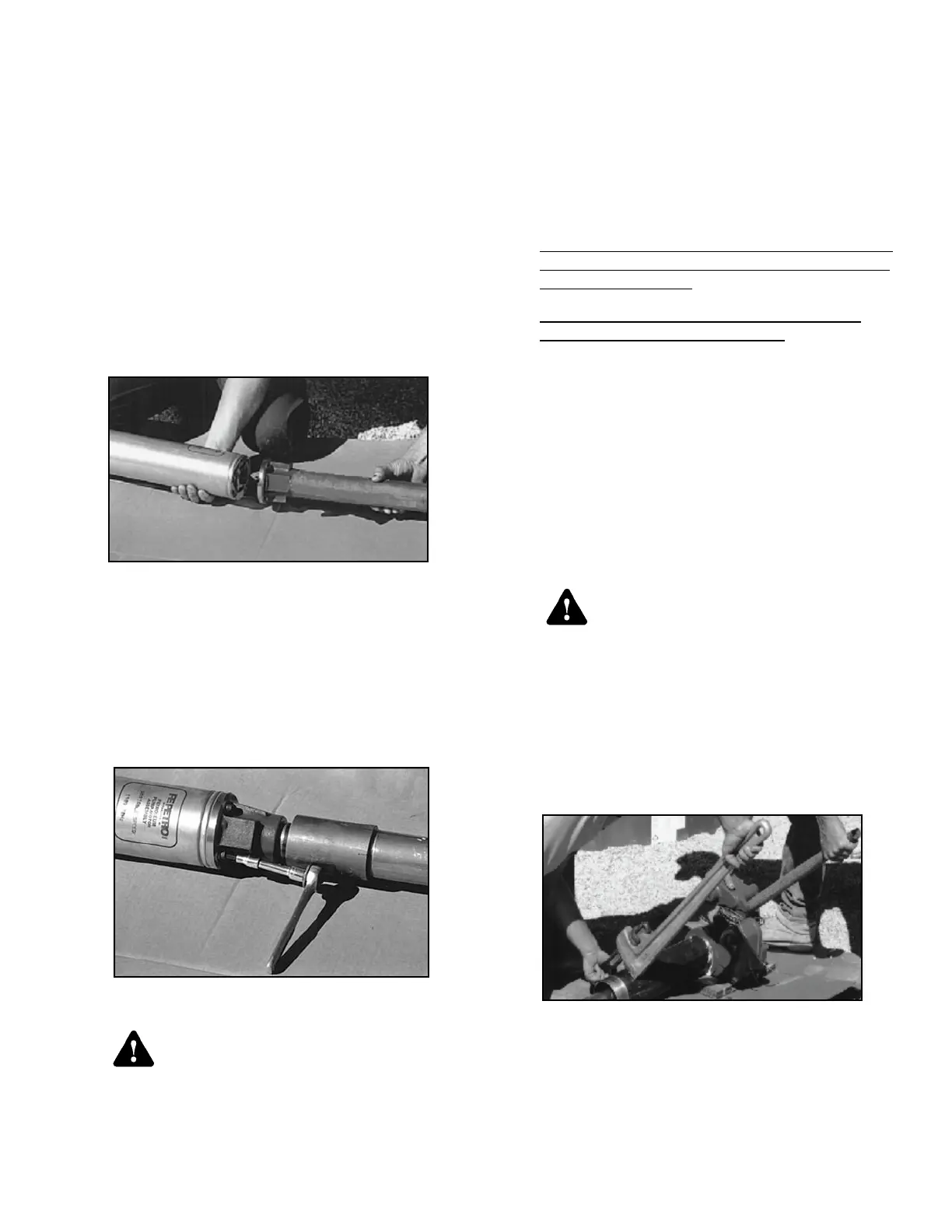

10. Mount PMA onto discharge head by aligning

locating pin on PMA with hole in discharge head,

assuring that the lead assembly in the motor

discharge head is seated in its notched position,

and that the PMA gasket is properly in place.

11. Tighten PMA onto discharge head using four cap

screws and lock washers supplied. A cross bolt-

tightening pattern is recommended for securing

PMA (Figure 2).

Figure 2: Tighten Bolts

The motor discharge head must not be

rotated more than one full rotation in

either direction. Rotation could cause

damage to the electrical connections

in the conduit, creating a risk of lethal

electrical shock or equipment failure.

Note: Before assembling the PMA to the discharge

casting make sure the wire lead is properly set

and aligned in the discharge casting. Improper

alignment could damage the wire lead or motor

pins. Failure to push PMA up snug against the

discharge casting before tightening cap screws, or

failure to use a cross-pattern while tightening the

bolts could break the discharge casting or strip the

threads in the PMA.

Note: IST units without a VS4 sufx and STP units with a

VS2 sufx can only be electrically connected to an

IST-VFC or MagVFC.

STP or IST units with a VS4 sufx can only be

electrically connected to a MagVFC. Unlike FE

Petro’s standard pumps, the following pumps

cannot be interchanged with competitive models:

The variable speed PMA VS2 (which is part of IST •

units without the VS4 sufx or the STP units sufxed

with VS2)

The PMA VS4 (which is part of the IST and STP •

units with the VS4 sufx)

12. Apply a non-hardening, UL classied, gasoline-

resistant pipe sealing compound to the riser pipe

threads, if not already installed.

Failure to use a proper thread sealing

compound could result in a lack of

seal where the riser threads into the

tank opening, making it impossible to

perform a tank-tightness test. This may

also create a potential site for fuel to

leak into the environment and / or the

containment sump.

13. Slide riser over the PMA and tighten into manifold

threads (Figure 3). Maximum riser size is found

by taking the grade to tank mounting thread

measurement and subtracting the manifold height

and clearance (6" clearance recommended).

Figure 3: Attach Riser

Note: Riser material required for pump is 4.5" outside

diameter with a .188" wall. Minimum riser length

supplied by FE Petro is 7".

Warning

Warning

Loading...

Loading...