3

Note: Some underground storage tanks are ballasted

with water during construction. DO NOT use the

submersible pump to remove water from the tank.

The pump is designed for use with petroleum

products only, and pumping other uids will

seriously damage the unit. We do not recommend

immersing the pump in water, but, if this does

happen, immediately ll the tank with motor fuel

after the water is removed from the tank. Severe

corrosion takes place very quickly if the unit has

been submerged in water and is then exposed to

air. If the pump will not operate after gasoline is

put into the tank, remove the extractable portion,

remove the black plastic end cap from the pump

motor assembly (PMA), and turn the Allen screw

clockwise at the end of the PMA. This will break

free the PMA from any corrosion that may be

present. Reinstall the PMA end cap and the

extractable section into the pump housing.

Installer:

This instruction booklet MUST be left with the owner of the

service station at which the equipment is being installed.

Station Owner:

Retain these instructions for future use and provide them

to persons servicing or removing this equipment.

Installation Instructions

The piping and underground storage tank must be installed

using good standard industry practices. There are several

publications that can be used for reference, some of which

are:

Automotive and Marine Service Station Code, NFPA •

30A, Flammable and Combustible Code, NFPA 30, and

National Electrical Code, NFPA 70 (NEC), National Fire

Protection Association, Quincy, Mass.

Recommended Practices for Installation of Underground •

Liquid Storage Systems, The Petroleum Equipment

Institute, PEI / RP100, Latest Edition.

Recommended Practices for Installation of Aboveground •

Storage Systems for Motor Vehicle Fueling, The

Petroleum Equipment Institute, PEI / RP200, Latest

Edition.

Installation of Underground Petroleum Storage Systems, •

American Petroleum Institute, API Recommended

Practice 1615, Latest Edition.

Required Tools

Standard 3 / 4" drive ratchet wrench or breaker bar (no •

sockets required)

Standard at head screwdriver•

Wire cutter and stripper•

5 / 32" Allen wrench for securing set screw in telescoping •

pipe coupling (VL units only)

Pipe wrench (36" minimum) for tightening 4" Riser•

1 / 4" hex driver with socket and ratchet wrench, or 1 / 4" •

Allen wrench for attaching PMA

Measuring tape long enough to reach bottom of the tank •

from 30" to 70" above the tank

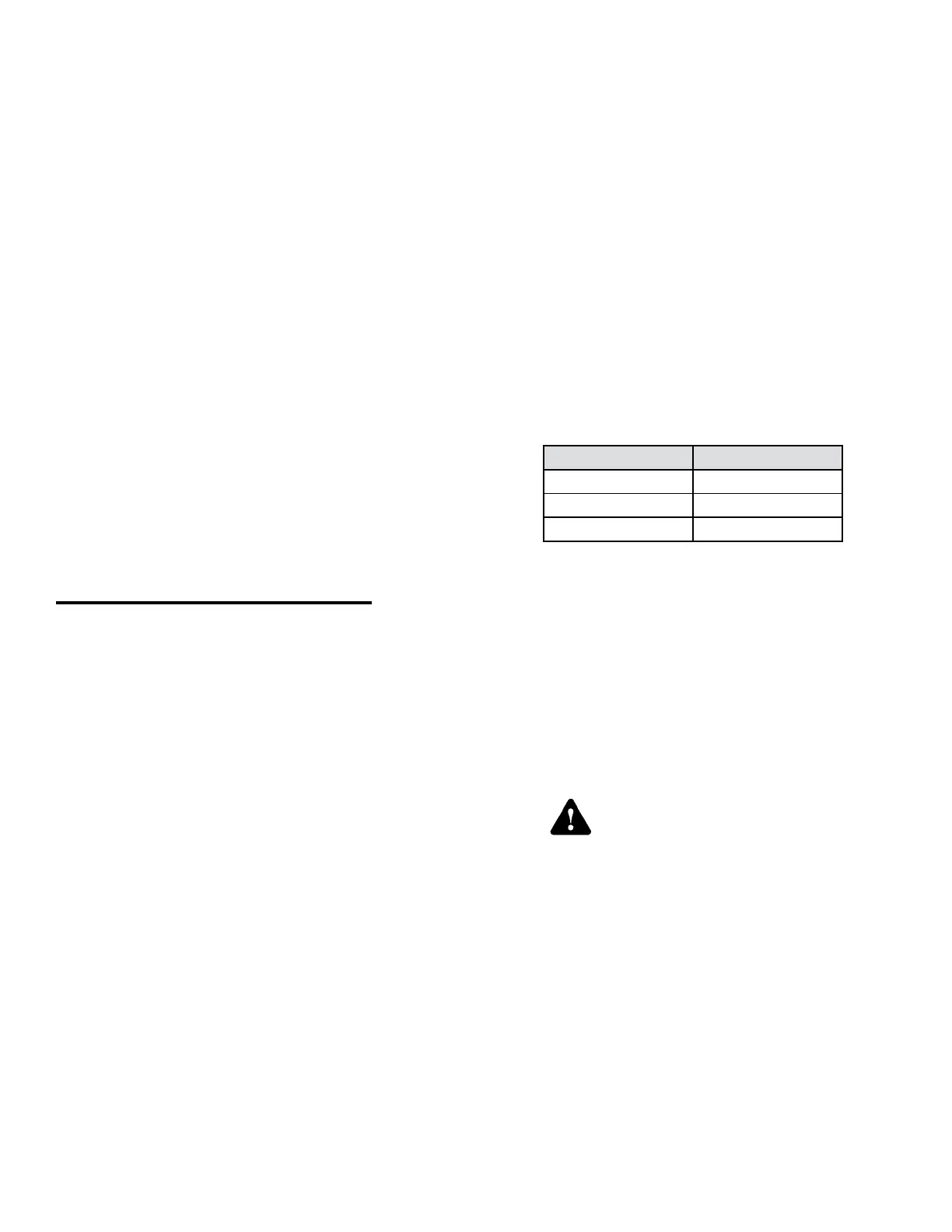

Note: All wiring must conform to applicable guidelines in

accordance with all federal, state, and local codes.

Failure to comply with all applicable guidelines

could result in an unsafe installation. Use the

following table for maximum wire length to wire

gauge ratios for submersible wiring:

Wire Size Maximum Run

10 gauge 650 feet

12 gauge 400 feet

14 gauge 250 feet

Preparation

1. Fill out the Warranty Registration Card and return

it to FE Petro.

Note: If your STP / IST does not operate correctly or

there are any questions concerning installation or

service, please contact FE Petro Technical Service

at (800) 225-9787.

2. Disconnect power to the submersible pump at the

electrical supply box (if already installed).

3. Tag and lock out electrical circuit breakers so they

are not turned on accidentally.

If installing xed length pump (non-•

variable) with PMA mounted, go to

“secure to tank” section.

If installing variable length pump •

continue with this section.

If installing xed length pump (non-•

variable) without PMA mounted,

complete “mounting PMA” section,

then go to “secure to tank” section.

Warning

Loading...

Loading...