5

Example

Grade to tank mounting threads (bury depth) 48"

Minus manifold height without leak detector

(w / leak detector height = 12.50)

-11"

Minus 6" for top clearance (2" minimum) -6

= Maximum riser size 31"

Length Setting

14. Cut wire tie(s) securing the motor wire at the top of

the pump; lay the wires out above the pump head

so that wires can feed through conduit freely when

setting length (Figure 4).

Figure 4: Cut Wires

Failure to cut wire ties prior to setting

pump length could result in damage to

electrical motor wires, presenting a risk

of lethal electrical shock or equipment

failure.

15. Measure from the bottom of the tank to the top of

tank mounting threads. Subtract the distance for

clearance between the PMA and the bottom of the

tank (6" recommended). This is the length to which

the pump should be extracted, measured from the

bottom of the riser threads to the bottom of the

motor end bell.

Note: 6" clearance provides a 5" clearance from the

pump motor end bell to the bottom of the tank once

the riser is screwed into tank mounting threads.

Tank + thread measurement 96"

Distance from bottom (5") + riser thread

engagement (1")

-6"

= Length (bottom of riser to end bell) 90"

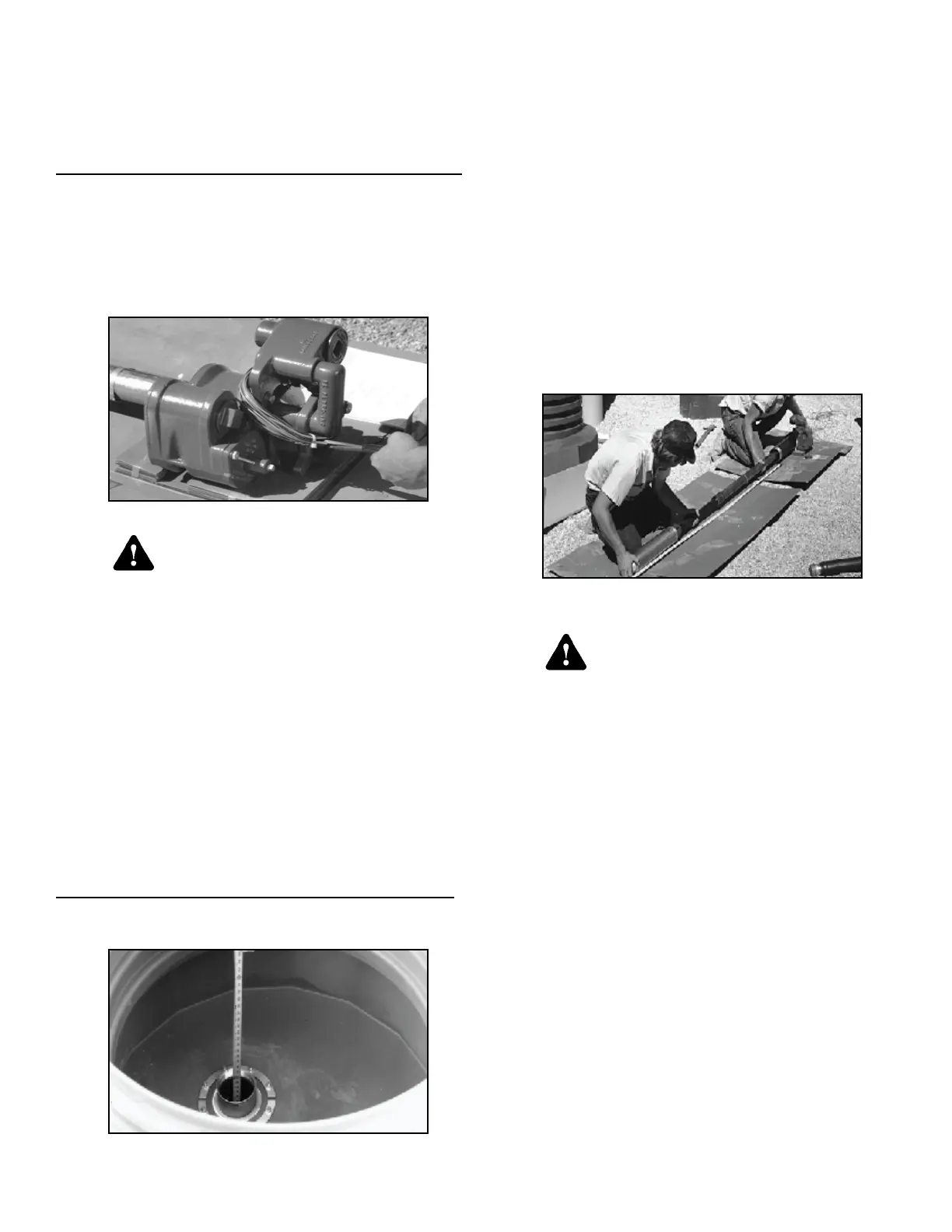

Figure 5: Measure Tank

16. Hold the manifold securely to the surface to

prevent damage while setting length.

To allow movement of the telescoping pipe,

verify that none of the pipe coupling setscrews

are in contact with the pipe. Lay a tape measure

out to accurately measure the distance from the

bottom of the riser to the bottom of the pump

motor end bell.

17.

Grasp the pump just above the PMA and pull rmly,

extending to the length required (from Step 15).

Note: Use care to ensure electrical conduit wires

at the top of the discharge manifold are not

damaged during length setting. If column pipe

is extended beyond desired length have a

second person retract conduit wires as column

pipe is shortened. This will prevent damage to

conduit wires.

Figure 6: Measure Riser

The motor discharge head must not be

rotated more than one full rotation in

either direction. Rotating could cause

damage to the electrical motor wires,

presenting a risk of potentially lethal

electrical shock or equipment failure.

Note: O-ring seals inside the locking coupling may have

sealed to the column pipe during shipping. Spin the

motor discharge head slightly (not more than one

full rotation) while pulling to loosen the O-ring seals.

Warning

Warning

Loading...

Loading...