6

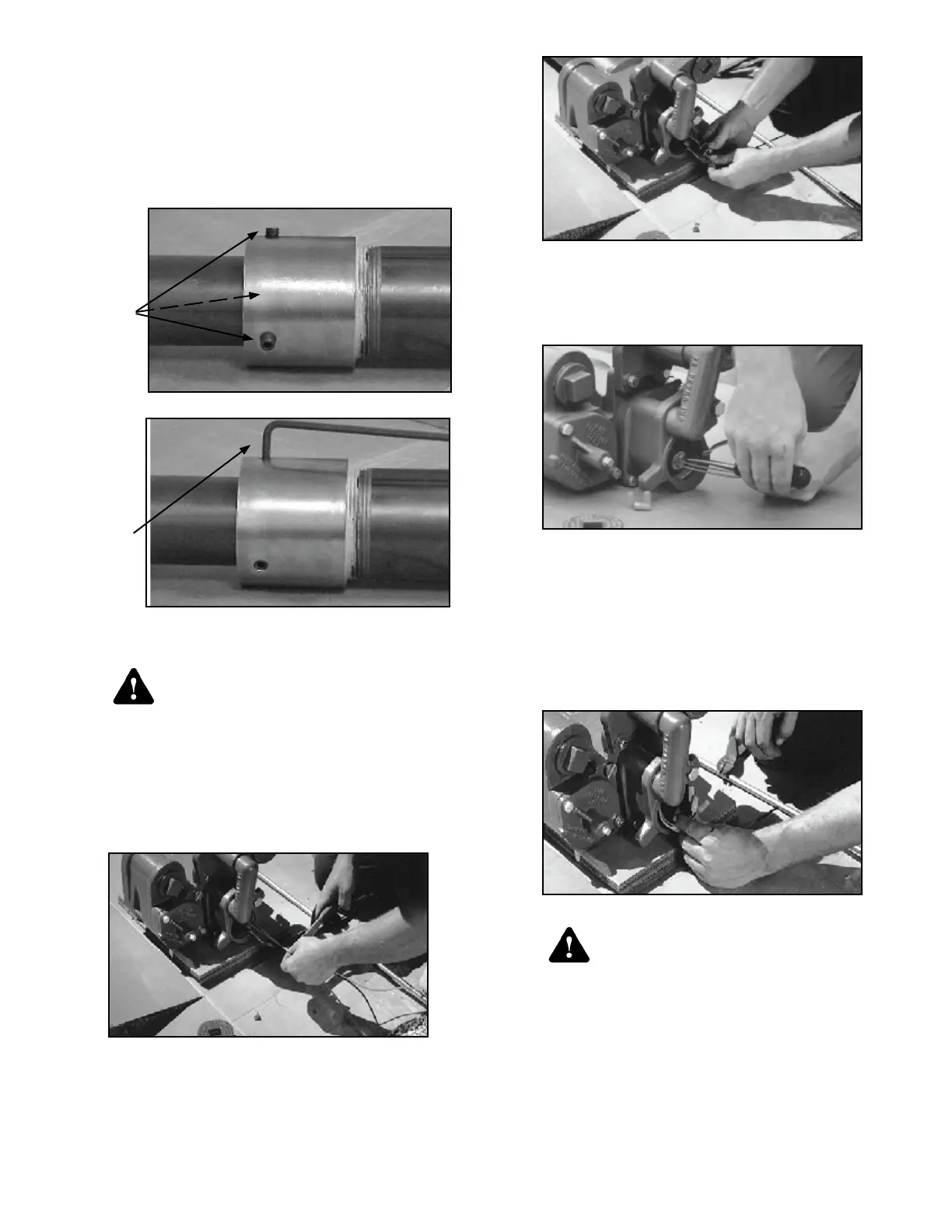

18. Once the length is correct, lock the STP length by

tightening all three coupling setscrews. Tighten the

setscrews nger-tight, making sure they come into

contact with the pipe (Figure 7).

19. Tighten each setscrew an additional full turn

minimum. The head of the setscrews should be

ush or below ush with the outer surface of the

coupling (Figure 8).

Setscrews

3 places

Figure 7: Install Setscrews

5 / 32"

Allen

Wrench

Figure 8: Tighten Setscrews

Failure to properly tighten the coupling

setscrews at this stage could present

a risk of death, serious bodily injury

and / or equipment damage due to

movement of pipes during installation.

PMA Wiring

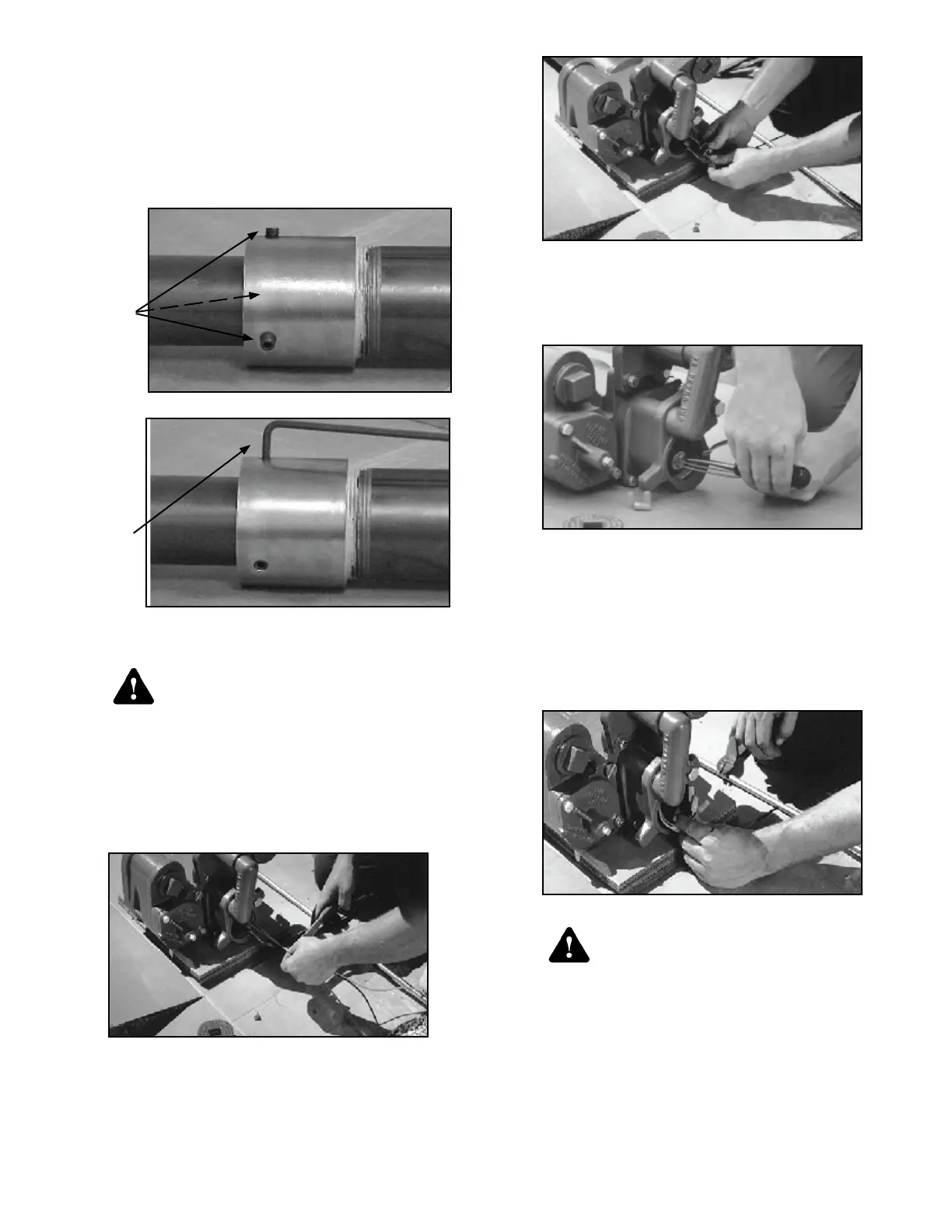

20. Measure approximately 6" of wire from the

discharge manifold; cut off excess wire and

discard (Figure 9).

Figure 9: Measure and Cut Wire

21. Place the three wires through the contractors plug

assembly (from hardware pack p / n 400301903)

as shown in gure 10.

Figure 10: Wire Through Contractor’s Plug

22. Using the screwdriver slide the contractors plug

into its seat in the discharge manifold. Tighten the

two screws in the contractor plug to secure it in

place (Figure 11).

Figure 11: Attach Contractor’s Plug

23. Strip the wire insulation back approximately 3 / 8"

on the three motor leads. Using the wire nuts

supplied (from hardware pack p / n 400301903)

connect to the wires from the electrical connector

orange to orange, black to black, and red to red.

24.

Coil the wires and push into the discharge manifold

cavity using care to ensure wires are not damaged

on discharge manifold threads (Figure 12)

.

Figure 12: Push Wires into Cavity

Damage to the electrical conduit wires

creates a risk of lethal electrical shock

and equipment failure. Do NOT use

equipment if electrical wires have

been damaged (contact FE Petro for

assistance).

25. Tighten the discharge head cover (from hardware

pack p / n 400301907) in place using a 3 / 4" ratchet

or breaker bar (Figure 13).

Warning

Warning

Loading...

Loading...