REFER TO THE CHARTS ON PAGE 8 FOR THE

RECOMMENDED TUBE O.D. SIZES ON LIQUID AND

SUCTION LINES.

Undersized line sets will increase the refrigerant pressure drop

between the indoor evaporator and outdoor unit, resulting in a

decrease in system capacity. Oversizing the line sets may result in

excessive refrigerant charge, thereby making the system more

susceptible to liquid migration.

Condensing units are available with pre-charged, sweat-type copper

connecting fittings.

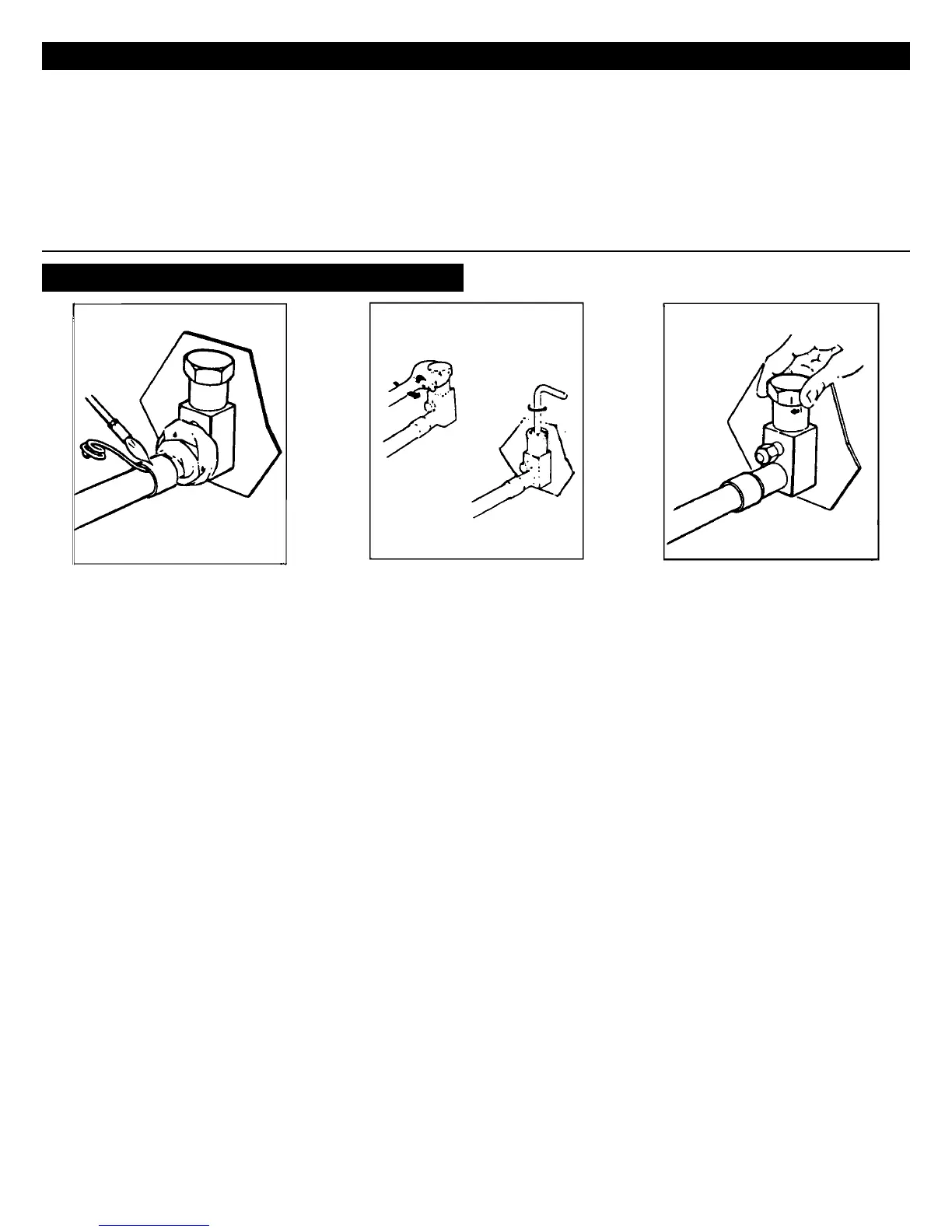

1. Remove the valve core from the

schrader port. Wrap a wet rag around the

copper stub. Flux the joint and braze with

silphos rod containing at least 10%

silver. DO NOT USE SOFT SOLDER.

Replace the valve core after brazing.

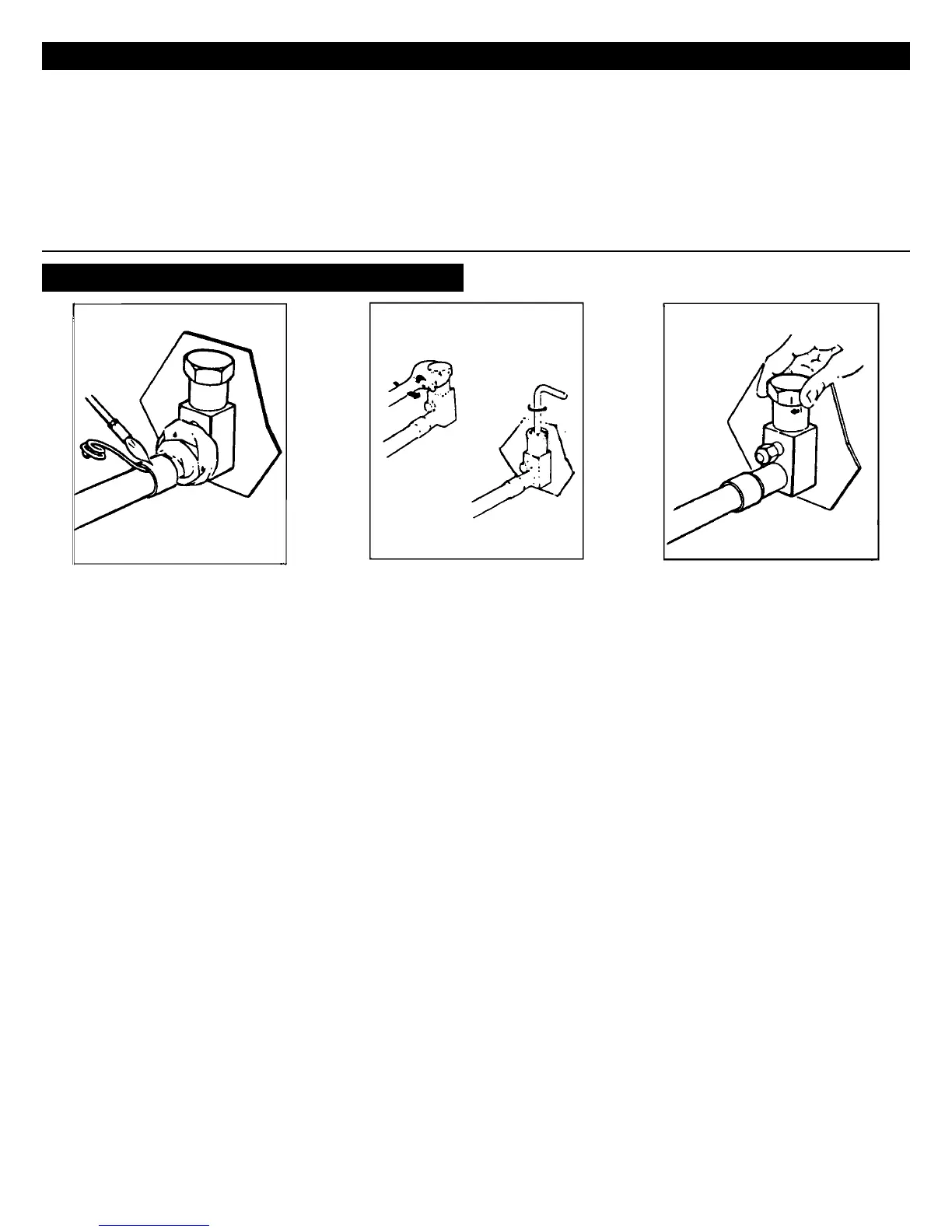

2. Leak-check all braze joints at

approximately 80 psi pressure, purge,

and evacuate the lines. NOTE: DO NOT

USE AIR TO LEAK-CHECK BRAZE

JOINTS. DRY NITROGEN SHOULD BE

USED.

3. This is not a back-seating valve. To open

the valve cap use an adjustable wrench.

To open the valve, insert a hex wrench

(

3

/16" for the liquid line,

5

/16" for the vapor

line) into the stem and back out

counterclockwise until the valve stem

just touches the retaining ring. Do not

over tighten.

4. Replace the valve cap finger-tight, then

tighten an additional

1

/

12 turn or

1

/

2 hex

flat. A metal-to-metal seal is now

complete.

COPPER SUCTION & LIQUID LINES

SWEAT-TYPE CONNECT FITTINGS

6

Loading...

Loading...