5.4 Resetting IP addresses to the factory setting

1.Set all switch elements for address setting DIL1 (1...6)

and DIL2 (1...2) to “ON”.

2.Switch bus node off and back on.

3.Set IP address via dynamic addressing è 5.3.

5.5 Configuration with “Generic Ethernet Module”

Integrate participants into the project and configure

them

è Documentation of the control system

Example with software STUDIO5000 from

ROCKWELLAUTOMATION:

Integration and configuration of the bus node

can only take place as long as there is no online

connection to the controller è Menu “Commu

nications” è “Go Offline”

1.In the “Controller Organizer” window in the “I/O Config

uration” area, open the dialogue window “Select Mod

ule Type” with a click of the right mouse button on “Eth

ernet” and with the context command “New Module”.

2.In the “Catalog”, select the module “Generic Ethernet

Module” from the table. To simplify the search, limit the

selection with the text filter.

3.Click on “Create” to confirm the selection.

The “Module Properties” dialogue window opens.

4.In the “Name” text field, enter a designation for the bus

node.

5.In the “Comm Format” list field, select the data format:

– “Data-SINT” (standard)

– “Data - SINT - With Statusbyte” with use of status

bytes over a separate connection

– “Data - INT” with usage of Word-based devices, e.g.

analogue module

6.Calculate the total size of the assigned address space.

7.Dependent on the I/O assignment for “Input” and

“Output”, input the following connection parameters.

Connection Parameters

Instance Size

1)2)

Variable Assembly Length Inputs

4)

101

Variable Assembly Length Outputs 100

Single Port Inputs 111 8

3)

Single Port Outputs 110 8

Dual Port Inputs 121 16

3)

Dual Port Outputs 120 16

Dual Port Inputs 131 32

3)

Dual Port Outputs 130 32

Dual Port Inputs 141 64

3)

Dual Port Outputs 140 64

1) Calculate the total size in bytes of the assigned address space

2) For “Data - INT”: Cut value in half

3) Increase value by 2 prefixed status bytes only if DIL switch

2.5 = ON è 5.2

8.Optional: To use status bytes over a separate connec

tion, input the following parameters.

Connection Parameters

Instance Size

Status Input 103 2

Status Output (Heartbeat) 254 –

9.For “Configuration”, enter the following values:

“Assembly Instance”=102 and “Size”=0

10. Enter IP address of the bus node.

11. Click on “Apply” to accept the inputs.

12. Close the dialogue window with “OK”.

In the “Controller Organizer” window in the “I/O Configur

ation” area, the bus node appears under “Ethernet” as a

newly integrated participant.

Using participant properties

è Documentation of the control system

Characteristic

Feature

Vendor Name Festo Corporation

Vendor ID 26 = 1A

h

Device Type 12 = 0C

h

Product Code 6001 = 1771

h

Major Revision 1

Status Current status of the bus node

Serial Number is displayed

Product Name CTEU-EP

Input Size/Output Size 0 ... 64 bytes

AssemblyInstance è Table “Connection Paramet

ers”

Extended EtherNet/IP participant properties

Min. bus cycle time (Reques

ted Packet Interval, RPI)

1 ms

Connections

Total of all connections Max. 32

Exclusive Owner Max. 1

Input only Max. 32

Listen only Max. 31

1)

1) Only with simultaneous connection “Exclusive Owner” or “Input

only”

5.6 Configuration with device master file (EDS file)

To simplify set-up of the CTEU-EP bus node, Festo makes

a device description file (EDS) available è www.festo.

com/sp.

The EDS file contains all information required to integrate

the CTEU-EP into the hardware configuration of your con

trol system.

Note...................................

Requirements

The software for configuration of your control system

supports import of EDS files.

5.7 Changing start addresses of inputs/outputs

è Documentation of the control system

In most cases, the control system handles the assignment

of the input/output addresses and the diagnostic addres

ses.

5.8 Setting up “QuickConnect” (QC) EtherNet/IP

function

è Documentation of the control system

Activate “QuickConnect” in the control system.

Activate “QuickConnect” via attribute 12 of the TCP/IP

interface object (factory setting: deactivated).

Note...................................

With use of the EtherNet/IP function “QuickConnect”,

Auto-Negotiation and Crossover detection (Auto-MDI/

MDI-X) are not available. Assignment of the pins for

transmitted and received data at the TP2 connection is

crossed.

Deactivate Crossover detection in the hardware con

figuration of the network neighbour (“Partner Port)”.

Set baud rate to 100 Mbit/s.

Activate full-duplex mode.

Select interconnecting cable dependent on pin as

signment of network connection of product connec

ted to TP2:

– Crossover-cable with identical pin assignment of

the ports

– Patch-cable with different pin assignment of the

ports

5.9 Check network communication

Note...................................

Functional test

– The LED NS is illuminated green (with faultless com

munication between control system and bus node).

– The LEDs TP1 or TP2 flash green (è 7).

6 EtherNet/IP Objects

Object

class

In

stance

Name Type

1

h

1 Identity Object

4

h

è 5.5 Assembly Object

è “Connection Parameters”

47

h

1 Device Level Ring Object

48

h

1 QoS Object

F5

h

1 TCP/IP-Interface Object

F6

h

1...2 Ethernet Link Object

64

h

1...64 Discrete Output Byte Object

65

h

1...64 Discrete Input Byte Object

67

h

1...2 Diagnostics Object (Status

bytes)

68

h

1...2 Slave Information Object

69

h

1 System Object

6A

h

1...2 IPort Module Parameter Object

6B

h

1...2 Port Configuration Object

300

h

1...2 ISDU Access Object

1)

1) ISDU = Indexed Service Data Unit

For detailed information on the objects è www.festo.

com/sp è User documentation: “CTEU-EP” è Appendix

to operating instructions.

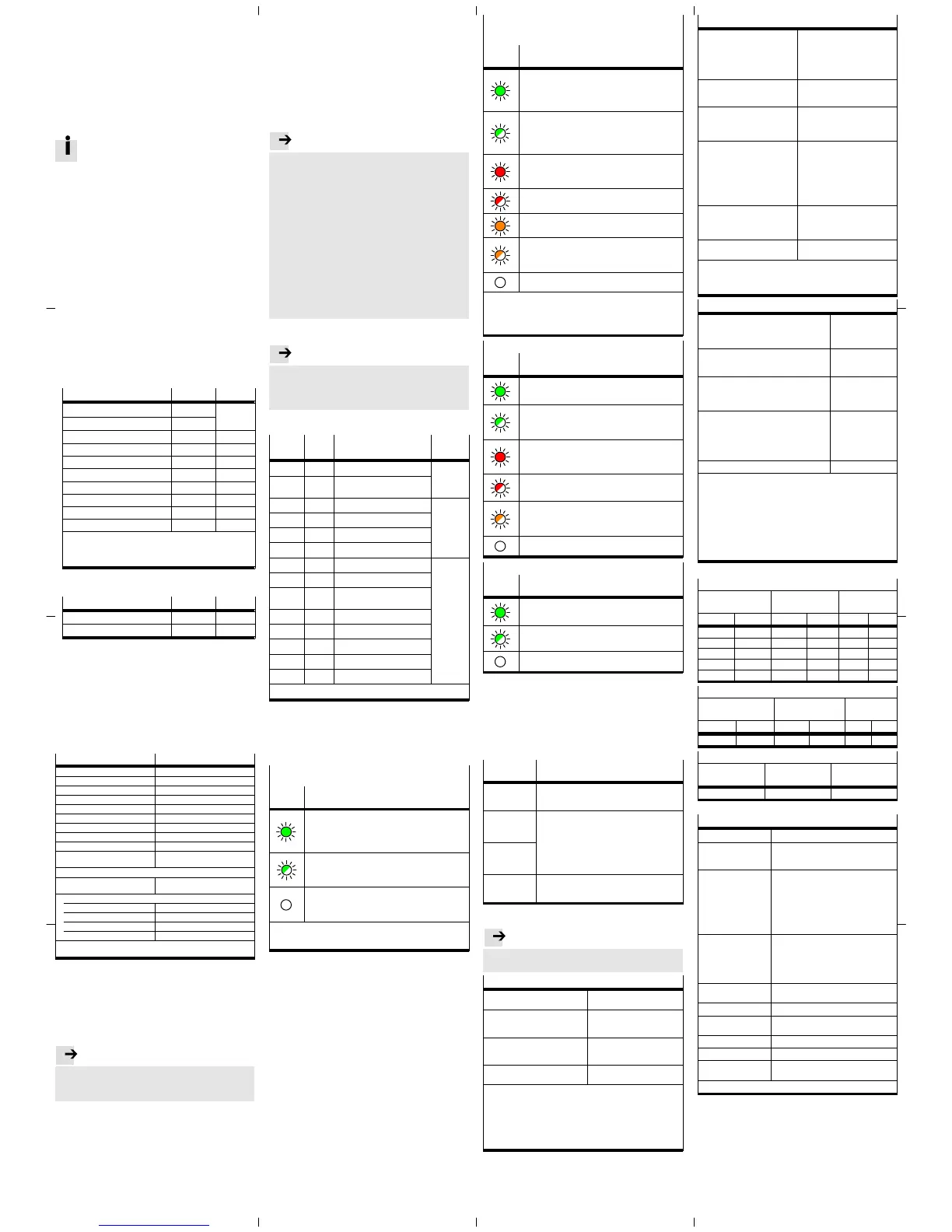

7 Diagnostics

PS – Status of the operating voltage supply

(Power System)

LED

display

Status and significance

LED illuminated green:

– Normal operating status

– Operating voltage is present (within the permissible

range)

– Load voltage is present (within permitted range)

1)

LED flashes green (flashing frequency: 1 Hz)

– Operating voltage is below the required voltage

– Load voltage is below the required level

1)

– Short circuit at the I-Port

1)

LED is off:

– Operating voltage is not present

– Operating voltage is below the voltage required for

diagnostic functions

1) This display only relates to the status of the load voltage if the

connected product is monitoring the load voltage and reports its

status to the bus node.

X1 and X2 – Status of the internal communication

between the bus node and the connected product

“I-Port Device1” or “I-Port Device2”

1)

LED in

dicator

Status and significance

LED illuminated green:

– Normal operating status

– I-Port Device 1 or 2 is connected correctly

– Operating and load voltage are connected (within

permitted range)

2)

LED flashing green:

– Status of diagnostics

– Undervoltage at system or additional power supply

– Connection between the bus node and the I-Port

Device is OK

LED illuminated red:

– I-Port Device is connected correctly, but the internal

communication is malfunctioning

– After commissioning, I-Port Device removed

LED flashing red:

– Error in the bus node

Both LEDs illuminated orange:

– Firmware update active

Both LEDs flash orange

– To locate the bus node (“module location”), e.g. dur

ing hardware configuration in the control system or

for troubleshooting

LED is off:

– No product connected to the bus node

1) Accessory with two I-Port interfaces required to connect two

products

2) This display only relates to the status of the load voltage if the

connected product is monitoring the load voltage and reports its

status to the bus node.

NS – Network status

LED

display

Status and significance

LED illuminated green:

– Normal operating status (“online”)

– Communication with the network is OK

LED flashing green:

– Communication with the network is OK

– IP address is assigned

– Connection is not configured

LED illuminated red:

– No communication to the network (“offline”), e.g.

through invalid bus address (example: address con

flict) or baud rate

LED flashing red:

– Communication with the network disrupted, time-out

detected (Bus time-out)

LED flashes orange:

– To locate the connected product (“module location”),

e.g. during hardware configuration in the control

system or for troubleshooting

LED is off:

– No network connection

TP1/TP2 – connection status “Link1” or “Link2”

LED

display

Status and significance

LED illuminated green:

– Normal operating status

– Network connection is OK

Both LEDs, TP1 and TP2 flash green:

– Data traffic

LED is off:

– No network connected

8 Maintenance

No special measures.

9 Accessories

è www.festo.com/catalogue

10 Glossary

Term/

abbreviation

Significance

QuickConnect Operating mode of the bus node, guarantees a

fast connection after restart of the network parti

cipants.

EtherNet/I P

Network protocol in automation technology

based on Industrial Ethernet (TCP/IP) for data

interchange between a higher-order control sys

tem (industry PC, PLC or IO Controller), network

participants and field devices (Field Devices/

Modules), e.g. valve terminals or drives

è www.odva.org

è www.modbus.org

ModbusTCP

PLC Programmable logic controller, also designated

system controller or controller for short (Program

mable Logic Controller, PLC)

11 Technical data

Note...................................

Technical data for the connected products can be ob

tained from the product documentation.

Electrical characteristics

Degree of protection through

housing

IP65/IP67

1)2)

Protection against electric shock

(protection against direct and

indirect contact)

through the use of PELV circuits

(Protective Extra-Low Voltage)

Disconnection of network

connections for operating voltage

power supply U

EL/SEN

Galvanically separated through

transformer (up to 500 V)

CE mark

3)

(see declaration of con

formity) è www.festo.com

In accordance with EU EMC Dir

ective

1) Requirement: Bus node mounted completely, plug connector in

the plugged-in status or provided with cover cap.

2) Connected products may only satisfy a lower degree of protec

tion.

3) The product is intended for use in an industrial environment.

Outside of industrial environments, e.g. in commercial and

mixed-residential areas, actions to suppress interference may

have to be taken.

General mechanical characteristics

Vibration and shock resistance

(in accordance with

IEC/EN 60068)

1)

– Vibration (part 2-6)

– Shock (part 2-27)

– Continuous shock (part 2-27)

Severity level (SL)

1)

for wall or

H-rail mounting

– Wall: SG2; H-rail: SG1

– Wall: SG2; H-rail: SG1

– Wall and H-rail: SG1

Temperature range

2)

– Storage/transpor t

– Operation

–20 … +70 °C

–5 … +50 °C

Corrosion protection The product is intended for in

door use in a typical industrial at

mosphere.

Avoid condensation.

Materials

– Housing

– Cover

– Fibre-optic cables

– Threaded bushing M12

– Threaded bushing M3

– Seals

– Screws

RoHS-compliant

PA reinforced

PA

PC

Brass, nickel-plated

Brass

NBR

Steel, galvanized

Dimensions

– Width

– Length

– Height

40 mm

91 mm

39 mm

Weight (bus node without cables

and sub-assembly)

98 g

1) Explanation of the severity level è Table “Explanation on

vibration and shock – severity level”

2) Connected products may only cover a less extensive temperat

ure range.

Power supply

Operating voltage for bus node and connec

ted products

1)

– Nominal value

– Tolerance range

24 V DC

18 … 30 V DC

2)

Load voltage for bus nodes and connected

products

1)

– Tolerance range 18 … 30 V DC

2)

Intrinsic current consumption at nominal op

erating voltage 24 V DC

from operating voltage supply for electron

ics/sensors (U

EL/SEN

)

Typ. 65 mA

(internal electronics)

Power rating of operating and load voltage

power supplies

1)3)

– Bus node on the connected product (e.g.

valve terminal)

– Bus node on the decentralised electrical

connection box CAPC

Max. 4 A

Max. 2 A

per I-Port Device

4)

Power failure buffering 10 ms

1) Separate, external fuses are required for the operating and load

voltage power supplies (no bus node-internal overload and po

larity reversal protection for the products connected via X1

and X2).

2) The tolerance range is dependent on the connected products.

3) Total power rating of operating and load voltage power supplies

PS and PL (residual current), maximum permitted current con

sumption of bus node and connected products

4) Total power rating of operating and load voltage power supplies

PS and PL (residual current), maximum permitted current con

sumption per I-Port Device

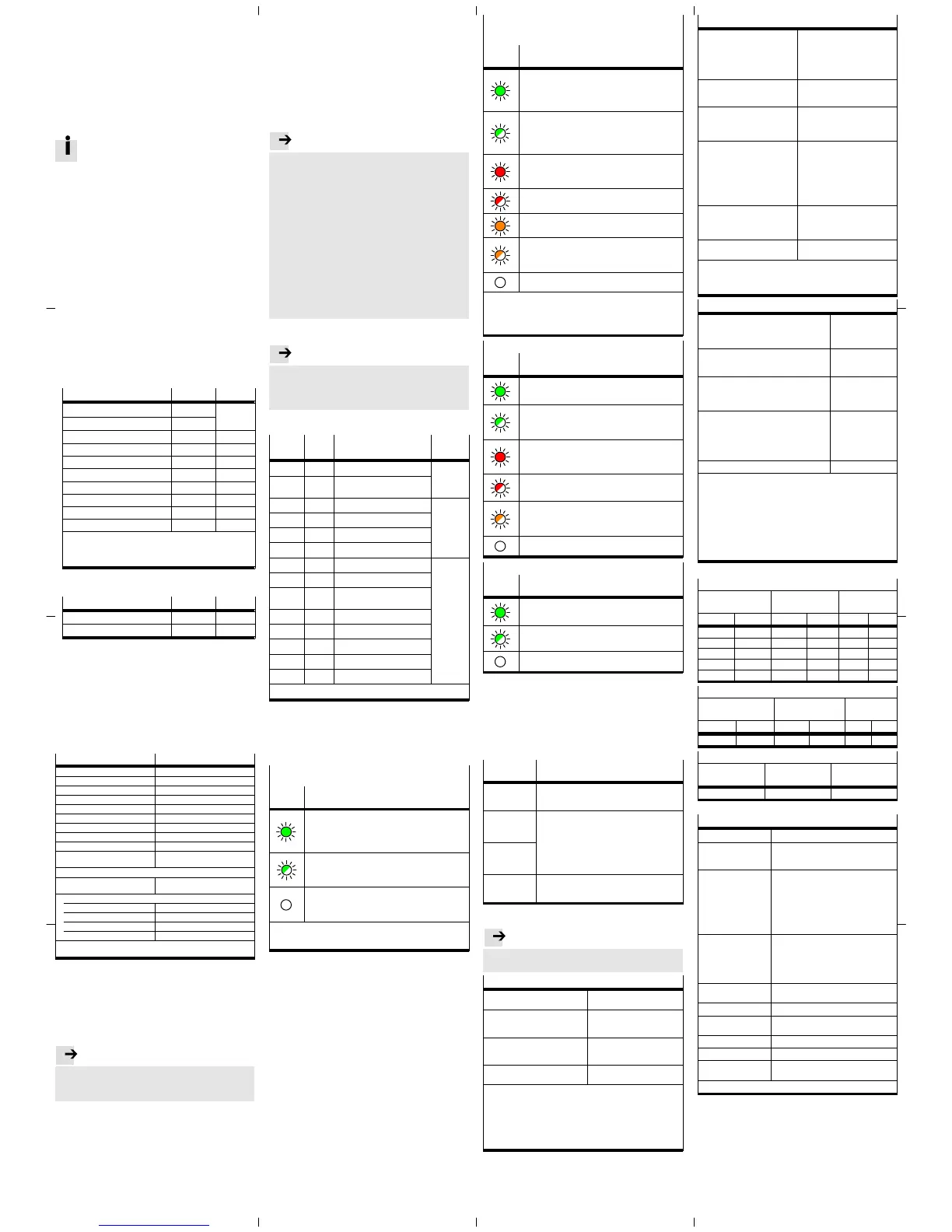

Explanation on vibration and shock – severity level

Vibration load

Frequency range

[Hz]

Acceleration

[m/s

2

]

Displacement

[mm]

SL1 SL2 SL1 SL2 SL1 SL2

2 … 8 2 … 8 – – ±3.5 ±3.5

8 … 27 8 … 27 10 10 – –

27 … 58 27 … 60 – – ±0.15 ±0.35

58 … 160 60 … 160 20 50 – –

160 … 200 160 … 200 10 10 – –

Shock load

Acceleration

[m/s

2

]

Duration

[ms]

Shocks per

direction

SL1 SL2 SL1 SL2 SL1 SL2

±150 ±300 11 11 5 5

Continuous shock load

Acceleration

[m/s

2

]

Duration

[ms]

Shocks per dir

ection

±150 6 1000

Network-specific characteristics

Network protocol EtherNet/I P or ModbusTCP

Supported protocols – Cyclic data exchange

– Simple Network Management Protocol

(SNMP)

Supported functions – QuickConnect (QC)

– Device Level Ring (DLR)

– Acyclic data access via Explicit Mes

saging

– Address Conflict Detection (ACD)

– Firmware update

– Integrated Switch

– System status via image table

System-specific func

tions

– Diagnostics information (system dia

gnosis, undervoltage, communication

errors)

– Web server (status of bus node and

connected products, serial number,

configuration)

Transmission techno

logy

Switched Fast Ethernet;

Design 100BaseTX

Transmission rate 10/100 Mbit/s, full-duplex/half-duplex

Bus cycle time (Reques

ted Packet Interval, RPI)

1 ms

Network connections 2 x socket, M12, D-coded, 4-pin

Crossover detection Auto-MDI/MDI-X

1)

Max. address volume

inputs/outputs

– 64 bytes I, 64 bytes O,

– 66 bytes I (with status bytes)

1) Only if QuickConnect is not active

Loading...

Loading...