8.2 Electrical Installation

WARNING!

Risk of injury due to electric shock.

• For the electric power supply, use SELV or PELV circuits that guarantee a reli-

able electric disconnection from the mains network.

• Observe IEC60204-1/EN60204-1.

1. If a screened cable is used: earth the shield at the cable end farther away

from the valve.

2. Install electrical connecting cable without squeezing, kinking or stretching.

3. Tighten the electrical connecting cable onto plug M12. Tightening torque:

maximum 0.3Nm

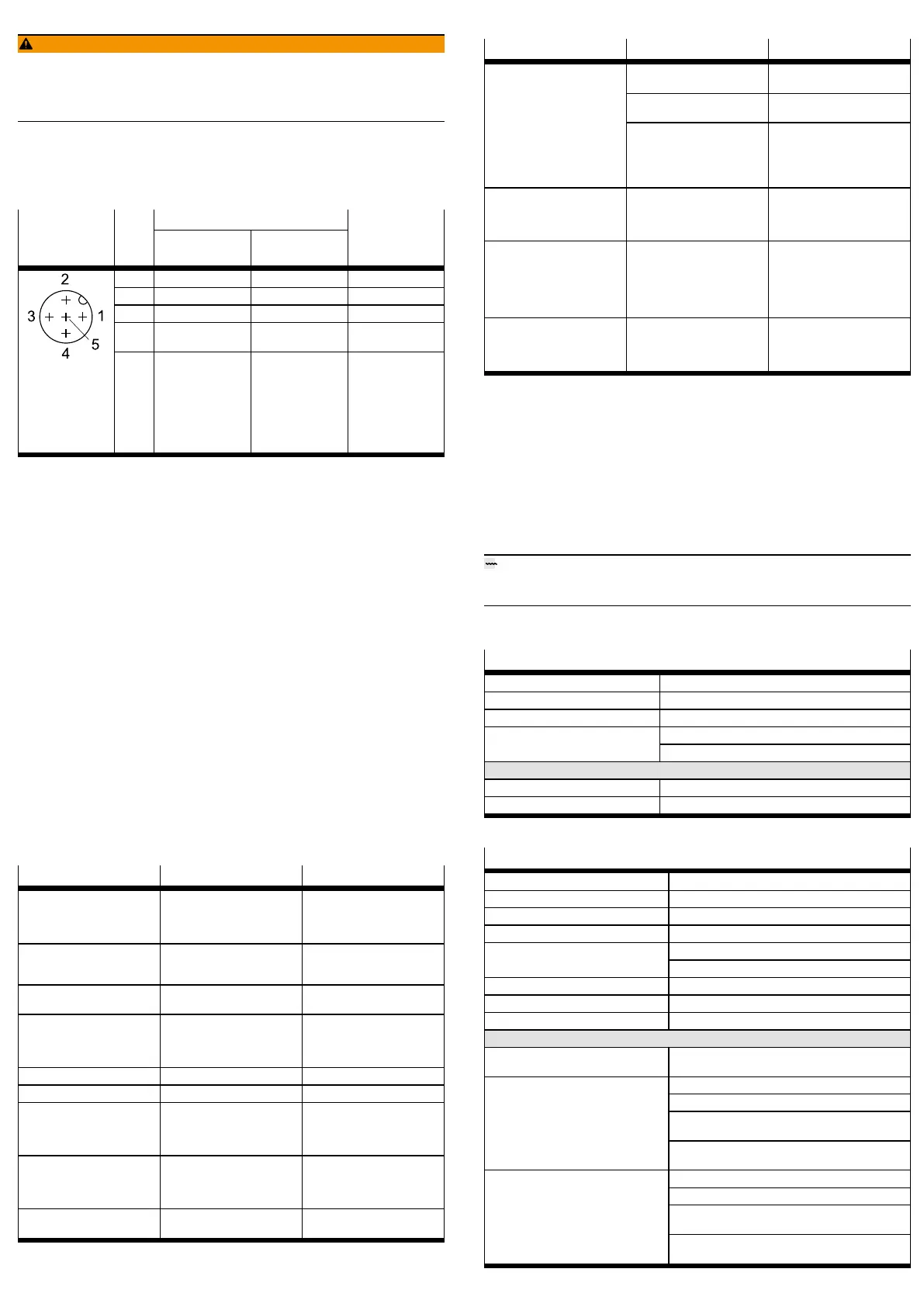

AllocationConnection Pin

Analogue Alternative

(digital input)

Wire colour

1)

(NEBU-M12...)

1 + 24 VDC + 24 VDC BN

2 Setpoint value (-) DI1 WH

3 GND GND BU

4 Setpoint value

(+)/PWM

DI0 BK

5 Actual value output

– related to pin 2

"Setpoint value

(-)" for type

VPPI -...- V1 -...

– related to pin 3

"GND" for

VPPI -...- A4 -...

DI2 GY

1) Colour code in accordance with IEC 60757:1983-01

Tab. 3 Pin Allocation for Plug M12, 5-pin

9 Commissioning

Requirements:

– The valve must be assembled.

– The pneumatic and electrical installation must be complete and checked.

1. Check operating conditions and critical limits è 14 Technical Data.

2. Switch on the power supply.

3. Switch on the compressed air supply.

4. If necessary, adjust the control response of the valve.

Setting the Control Response

The control response of the valve can be set in the menu of the TFT screen with

the help of the operating buttons on the top of the valve èDescription propor-

tional control valve VPPI -...- D èwww.festo.com/sp.

10 Cleaning

1. Switch off the following energy sources to clean the outside:

– Compressed air

– Operating voltage

2. Clean the outside of the product with a soft cloth. Do not use aggressive

cleaning agents.

11 Malfunctions

11.1 Diagnostics

The following table shows an overview of the error messages in the display.

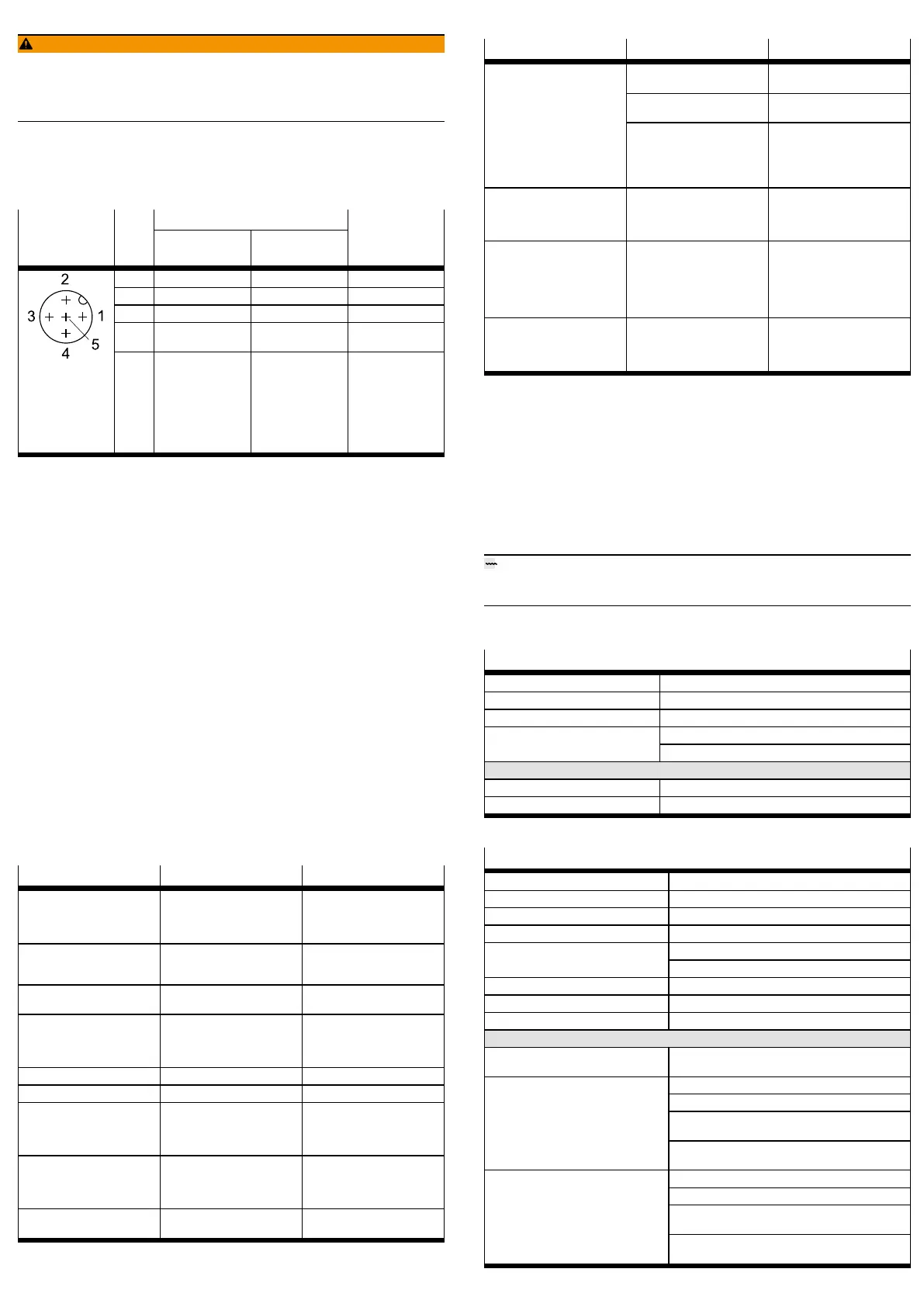

Error text in the display Error description Remedy

"Overheat" Working temperature is too

high. Valve is in temperature

shut-off.

Switch off the valve, let it cool

down and restart. Reduce ambi-

ent temperature or temperature

of medium.

"Cable break" Cable break setpoint input Check connection to setpoint

generator.

Replace supply cable.

"Oscillation" Continuous vibration detected. Select another parameter set

for application.

"No air supply" No input pressure p1.

Setpoint value not reached.

Increase input pressure p1.

Maintain permissible maximum

operating pressure

è 14 Technical Data.

"DC-supply low" Supply voltage is too low. Increase supply voltage.

"DC-supply high" Supply voltage is too high. Reduce supply voltage.

"Heat protection" Temperature critical, power

reduction active

Reduce ambient temperature or

temperature of medium. Ensure

sufficient compressed air sup-

ply.

"High deviation" Setpoint value not reached.

Input pressure p1 is too low.

Air consumption at the working

port is too high.

Increase input pressure p1.

Maintain permissible maximum

operating pressure

è 14 Technical Data.

"Setpoint high" Analogue setpoint value is too

high.

Correct setpoint value.

Tab. 4

11.2 Fault Clearance

Error description Cause Remedy

Operating voltage not applied. Check the operating voltage

connection.

No setpoint voltage. Check the controller and con-

nection.

Valve does not respond.

Working temperature is too

high. Valve is in temperature

shut-off.

Switch off the valve, let it cool

down and restart.

Reduce ambient temperature

and / or temperature of medi-

um.

Valve normally open:

The working pressure at (2)

falls to the level at (3) (ambient

pressure or vacuum).

Cable break setpoint input Check connection to setpoint

generator.

Replace supply cable.

Valve normally closed:

The working pressure at (2)

deviates upwards or down-

wards from the setpoint value

(working pressure is neither

pressurised nor exhausted).

Cable break setpoint input Check connection to setpoint

generator.

Replace supply cable.

Setpoint value not reached. Input pressure at (1) is too low. Increase input pressure at (1).

Maintain permissible maximum

operating pressure

è 14 Technical Data.

Tab. 5 Fault Clearance

12 Disassembly

1. Switch off compressed air supply.

2. Specify setpoint value 0bar.

3. Switch off operating voltage.

4. Remove electrical connecting cables.

5. Remove compressed air lines.

6. Dismantle the product.

13 Disposal

ENVIRONMENT!

Send the packaging and product for environmentally sound recycling in accord-

ance with the current regulations èwww.festo.com/sp.

14 Technical Data

General Technical Data

Valve function 3-way proportional-pressure regulator

Mounting position Any

Product weight [g] 370

RCMApprovals

KC

Materials

Seals HNBR

Housing PA-reinforced

Tab. 6 General Technical Data

Operating and Ambient Conditions

Ambient temperature [°C] 0…50

Storage temperature [°C] –20…+70

Temperature of medium [°C] 0…50

Degree of protection IP65

Compressed air to ISO 8573-1:2010 [7:4:4]Operating medium

Inert gases

Note on the operating medium Lubricated operation not possible

Climate class to EN60721 3k3

Nominal insert height

<3000m above sea level

Vibration resistance/shock resistance (as per IEC60068)

Note Explanation of the severity levels (SG)

è Tab. 8 Features of severity level (SL)

Individual valve fastened with screws: SG2

Individual valve on H-rail: SG1

Linking of max. 3 valves with lateral screw mounting:

SG2

Vibration (part 2-6)

Linking of max. 5 valves with lateral screw mounting:

SG1

Individual valve fastened with screws: SG2

Individual valve on H-rail: SG1

Linking of max. 3 valves with lateral screw mounting:

SG2

Shock (part 2 – 27)

Linking of max. 5 valves with lateral screw mounting:

SG1

Tab. 7 Operating and Ambient Conditions

Loading...

Loading...