AP-KA 65

11

GB

7.3 Fitting the guide plates [7]

The guide plates

[1-1]

are mounted on the perfo-

rated board according to the size and shape of the

workpiece to ensure safe guidance of the work-

piece and prevent it from tipping.

7.4 Fitting the additional roller [7 A]

The additional roller

[1-4]

can be fitted to help

guide the machine more accurately along long

workpieces.

Turn clockwise to mount securely in position.

Unscrew anticlockwise to remove.

8 Installing in a separate work plate

The Festool installation instructions contain:

– Dimensions of the cut-out for the adapter plate

– Dimensions of the hole pattern for positioning

the guide plates

After preparing the separate work plate, you

can continue fitting the other elements as de-

scribed in

chapter

7

.

9 Settings

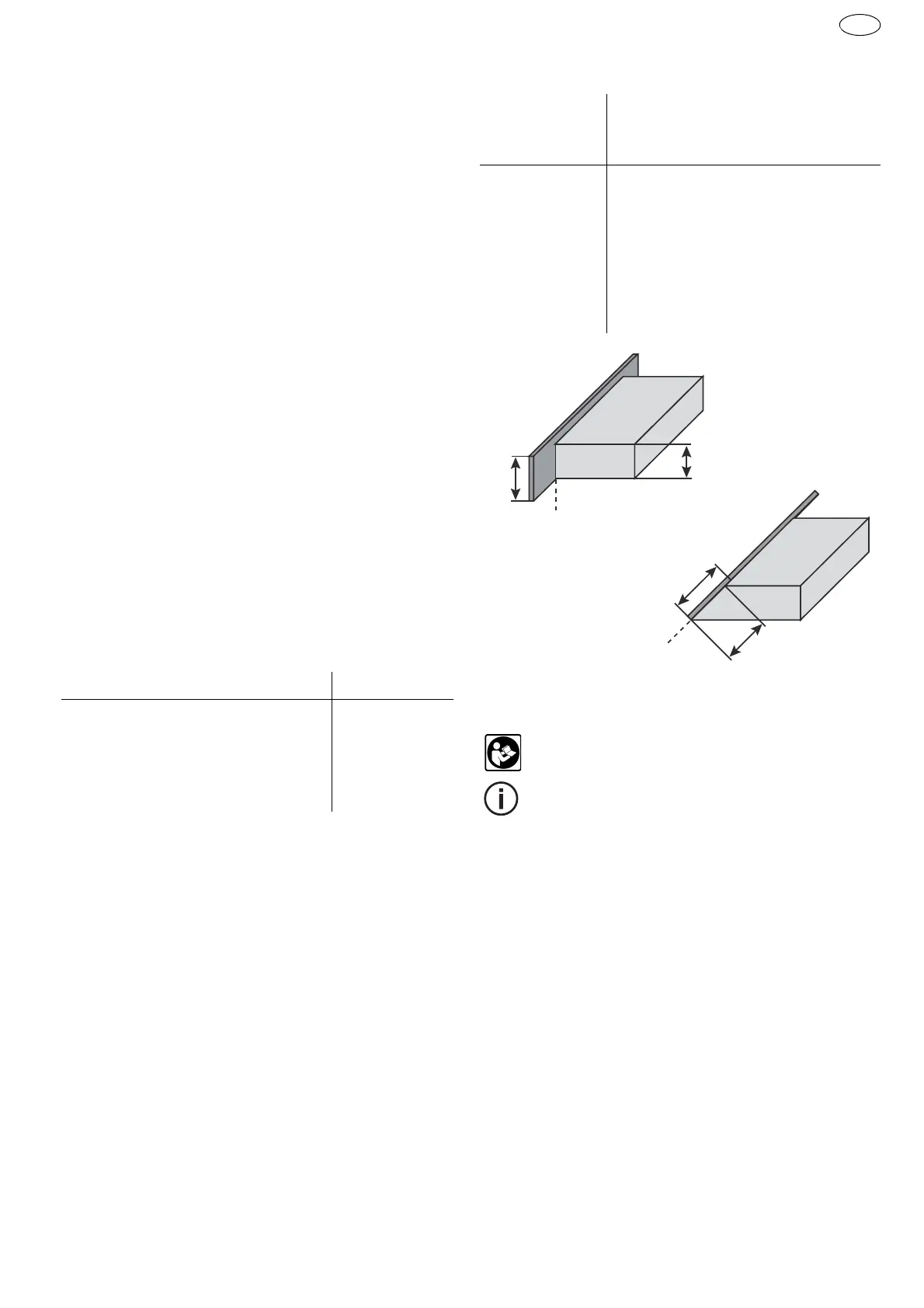

9.1 Adjusting the guide rail adapter [8]

The guide rail adapter

[1-11]

can be adjusted to

match the thickness of the edge band. The distance

between the workpiece and the adhesive roll can be

adjusted depending on the setting selected.

Lift the guide rail adapter

[1-11]

.

Change the setting to adjust the guide rail

adapter

[1-11]

to the thickness of the edge.

Lower the guide rail adapter

[1-11]

and engage

in position.

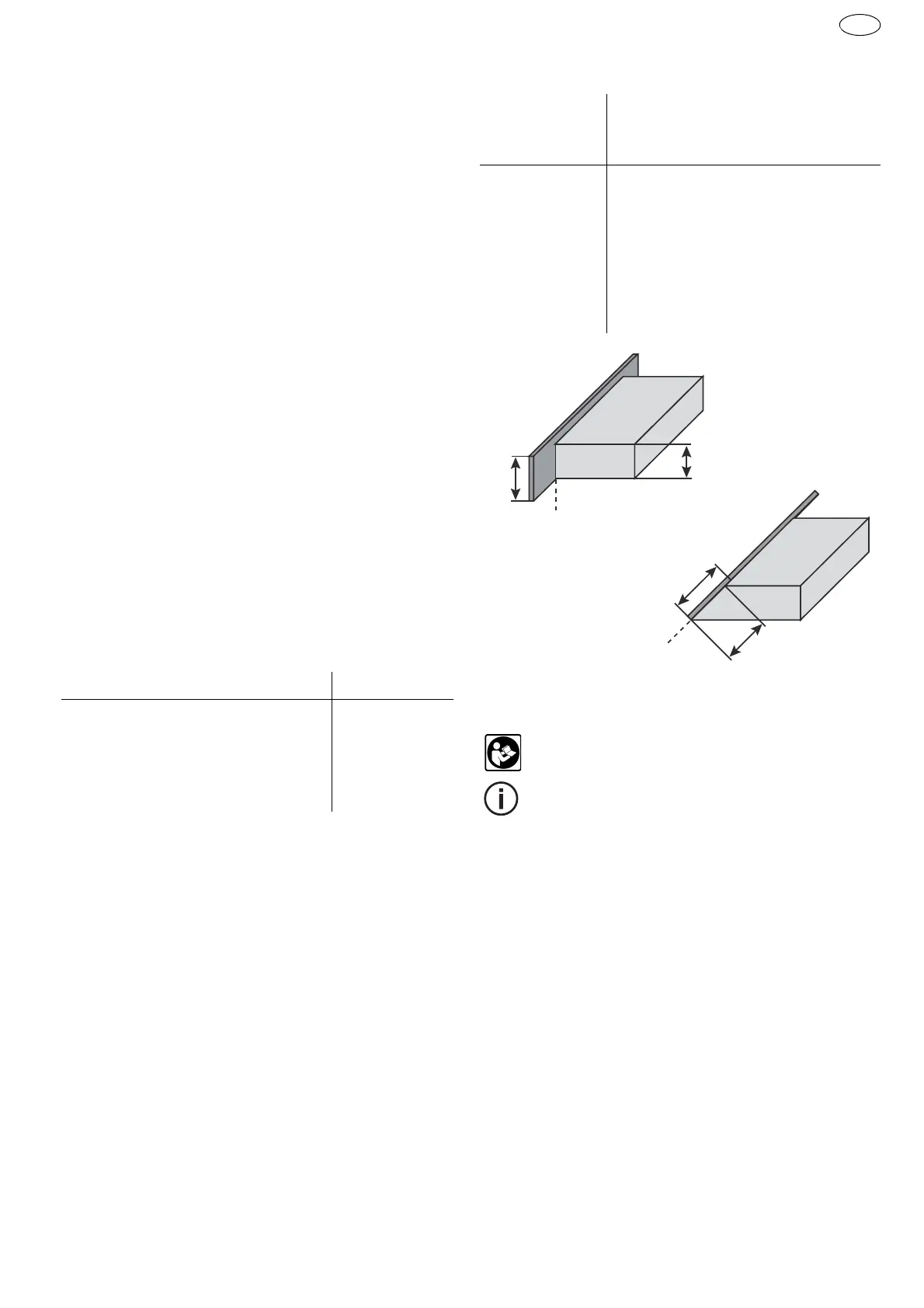

9.2 Adjusting the angle scale [1-10]

The angle scale

[1-10]

can be used to adapt the an-

gle of the stationary fixture to the sloping surface of

the workpiece.

Release the rotary angle adjustment knobs

[1-

7]

by turning anticlockwise

[3]

.

Set the angle.

Tighten the rotary angle adjustment knobs

[1-7]

by turning clockwise

[3]

.

Overview of required edge band width in relation

to the workpiece height and angle setting

9.3 Edge bander settings

Observe the operating instructions for the

edge bander KA 65.

The edge bander

cannot be moved to purg-

ing position

in the stationary fixture! In order

to carry out purging, the edge bander must

be removed from the stationary fixture.

10 Working with the machine

10.1 Attaching the edge band

Guide the edge band behind the guide pin

[1-9]

on the edging infeed to prevent the edge band

from slipping at the preset angle during the glu-

ing process

[9]

.

Press the start button on the edge bander once

to start feeding in the edging

[9]

.

Position the workpiece on the guide rail adapter

[1-11]

[10]

.

Press the start button on the edge bander again

and wait until adhesive visibly appears on the

edge band

[10]

.

Push the workpiece from right to left past the

edge bander while applying pressure on the

contact roller

[11]

.

Thickness of the edge band in mm Setting

0.5 - 0.8 0.5

0.8 - 1.3 1

1.3- 2.3 2

2.3- 3.0 3

Workpiece

height (h1) in

mm

Minimum height of the edge band

(h2) in mm for angle setting

0° 22.5° 45°

18

22 24 31

22

26 29 37

25

29 32 41

28

32 35 46

38

42 46 60

45°

Loading...

Loading...