Some applications require an attic floor installation of the

horizontal unit. In this case the unit should be set in a full size

secondary drain pan on top of a vibration absorbing mesh.

The secondary drain pan prevents possible condensate

overflow or water leakage damage to the ceiling. The

secondary drain pan is usually placed on a plywood base

isolated from the ceiling joists by additional layers of vibration

absorbing mesh. In both cases, a 3/4” drain connected to this

secondary pan should be run to an eave at a location that will

be noticeable. If the unit is located in a crawl space, the

bottom of the unit must be at least 4” above grade to prevent

flooding of the electrical parts due to heavy rains.

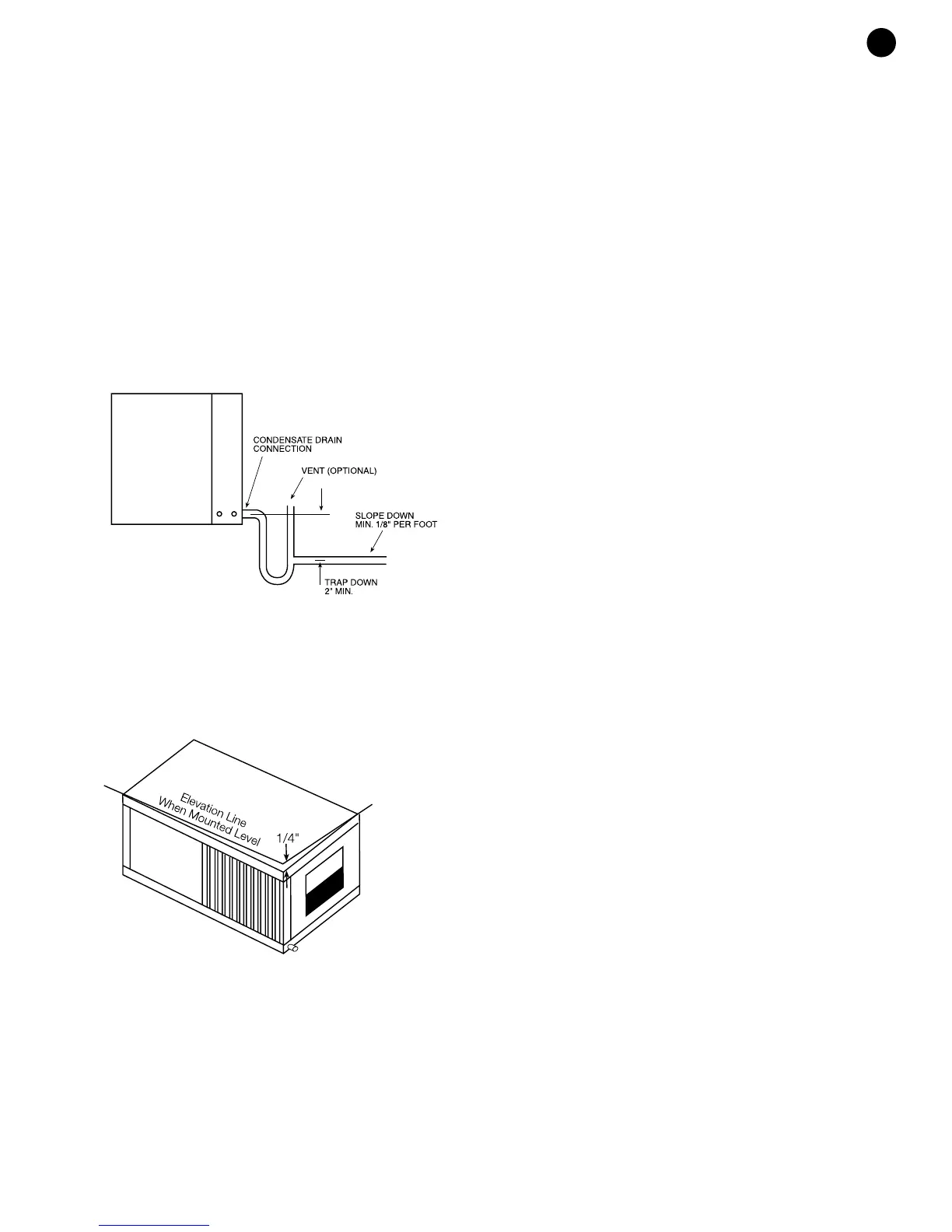

CONDENSATE DRAIN:

A drain line must be connected to the heat pump and pitched

away from the unit a minimum of 1/8” per foot to allow the

condensate to flow away from the unit.

This connection must be in conformance with local plumbing

codes. A trap must be installed in the condensate line to

insure free condensate flow. (Heat Pumps are not internally

trapped). A vertical air vent is sometimes required to avoid air

pockets. (See Figure #3). The length of the trap depends on

the amount of positive or negative pressure on the drain pan.

A second trap must not be included.

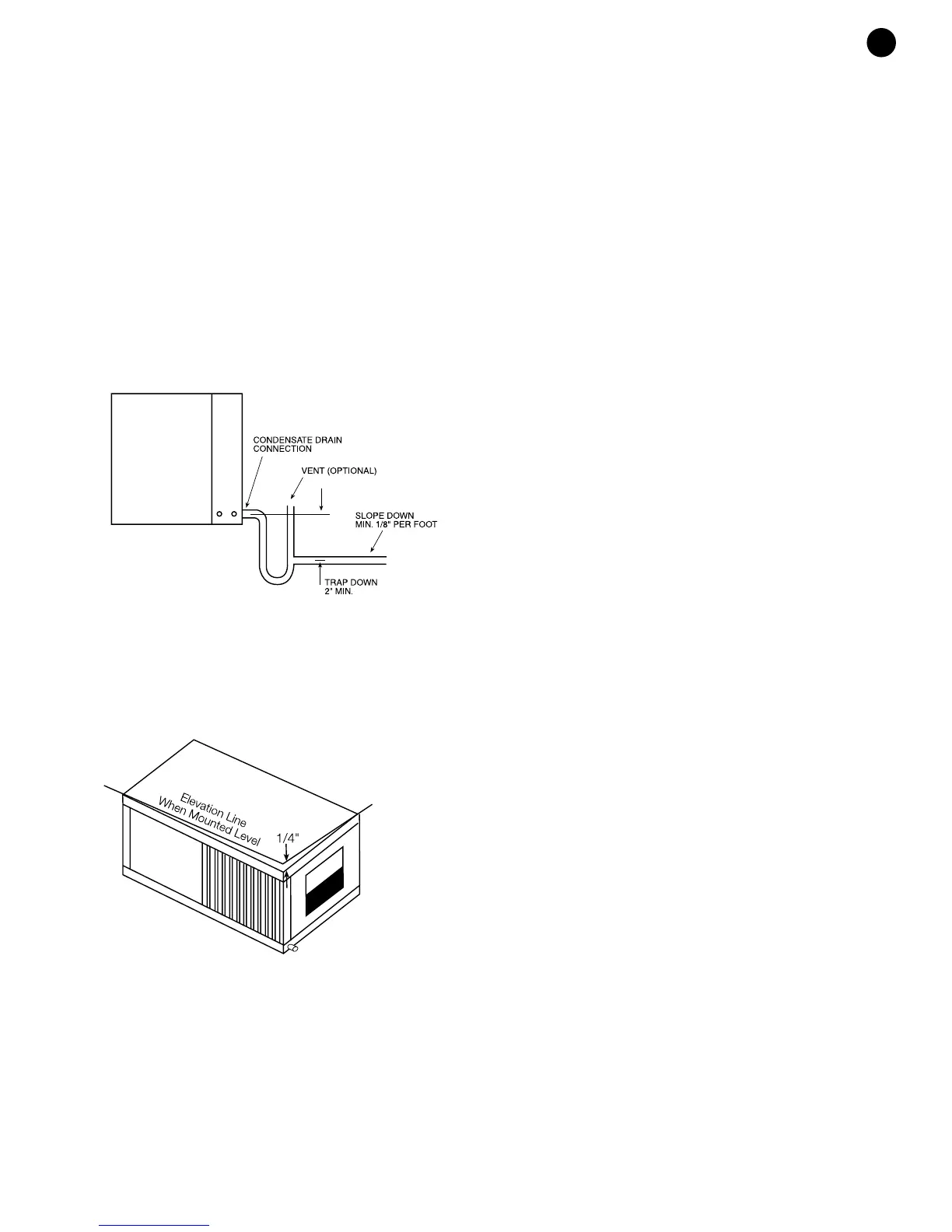

The horizontal unit should be pitched approximately 1/4”

towards the drain in both directions, to facilitate condensate

removal. (See Figure #4)

DUCT SYSTEM:

All EV models are provided with a return air duct flange and a

supply air outlet collar to facilitate duct connections. Refer to

the individual data specification sheet for physical dimensions

of the collar and flange.

A flexible connector is recommended for supply and return air

connections on metal duct systems. All metal ducting should

be insulated with a minimum of one inch duct insulation to

avoid heat loss or gain and prevent condensate forming during

the cooling operation. Application of the unit to uninsulated

duct work is not recommended as the unit’s performance will

be adversely affected. Do not connect discharge ducts directly

to the blower outlet. The factory provided air filter must be

removed when using a filter back return air grill.The factory

filter should be left in place on a free return system.

If the unit will be installed in a new installation with new duct

work, the installation should be designed using current

ASHRAE procedures for duct sizing. If the unit will be

connected to an existing duct system, a check should be

made to assure that the duct system has the capacity to

handle the air required for the unit application. If the duct

system is too small, larger duct work must be installed. Be

certain to check for existing leaks and repair.

The duct system and all diffusers should be sized to handle

the designed air flow quietly. To maximize sound attenuation

of the unit blower, the supply and return air plenums should

be insulated. There should be no direct straight air path thru

the return air grille into the heat pump. The return air inlet to

the heat pump must have at least one 90 degree turn away

from the space return air grille. If air noise or excessive air flow

are a problem, the blower speed can be changed to a lower

speed to reduce air flow.

ELECTRICAL:

All field wiring must comply with local and national fire, safety

and electrical codes. Power to the unit must be within the

operating voltage range indicated on the unit’s nameplate. On

three phase units, phases must be balanced within 2%.

Properly sized fuses or HACR circuit breakers must be

installed for branch circuit protection. See equipment rating

plate for maximum size. The unit is supplied with an opening

for attaching conduit. Be certain to connect the ground lead to

the ground lug in the control box. Connect the power leads as

indicated on the unit wiring diagram.

NOTE: Units supplied with internal electric heat require two

(2) separate power supplies. One for the unit compressor

circuit and one for the electric heater elements which also

powers the unit blower motor and control circuit.

Refer to the ELECTRIC HEATER PACKAGE OPTION section

on page 6 and figure #8. for wiring instructions, minimum

circuit ampacities and maximum fuse/breaker sizing.

THERMOSTAT CONNECTIONS:

Thermostat wiring is connected to the 7-position low voltage

terminal block located in the upper portion of the electrical

box. The thermostat connections and their functions are as

follows:

C Transformer 24 VAC Common

O Reversing Valve (energized in cooling)

Y Compressor contactor

R Transformer 24 VAC Hot

W2 Auxiliary Electric Heat (2

nd

stage heat) runs in

conjunction with the compressor

G Fan

E Emergency heat

3

EV SERIES

(Figure #3)

(Figure #4)

Loading...

Loading...