page 3 of 12

INSTALLATION OF SWG POWER VENTER

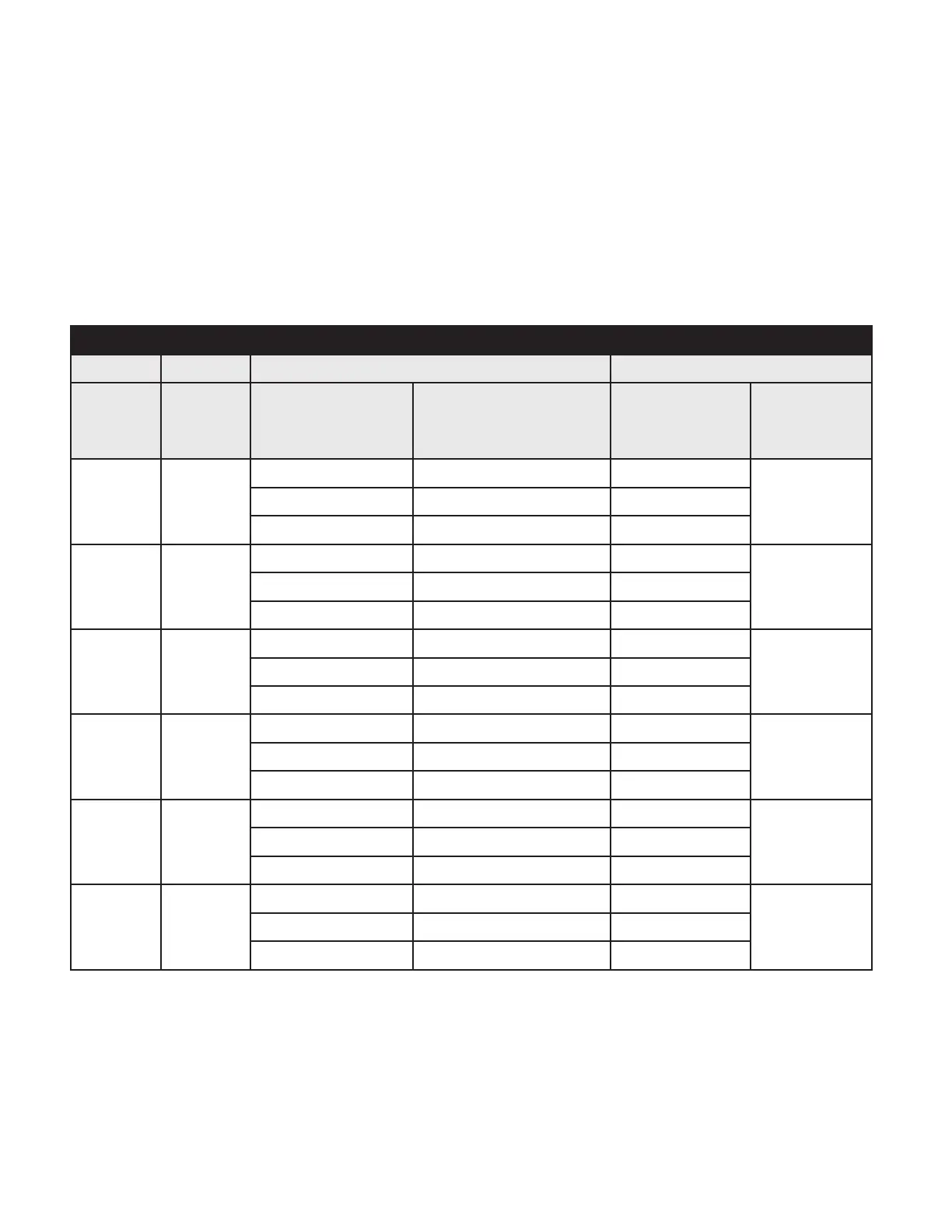

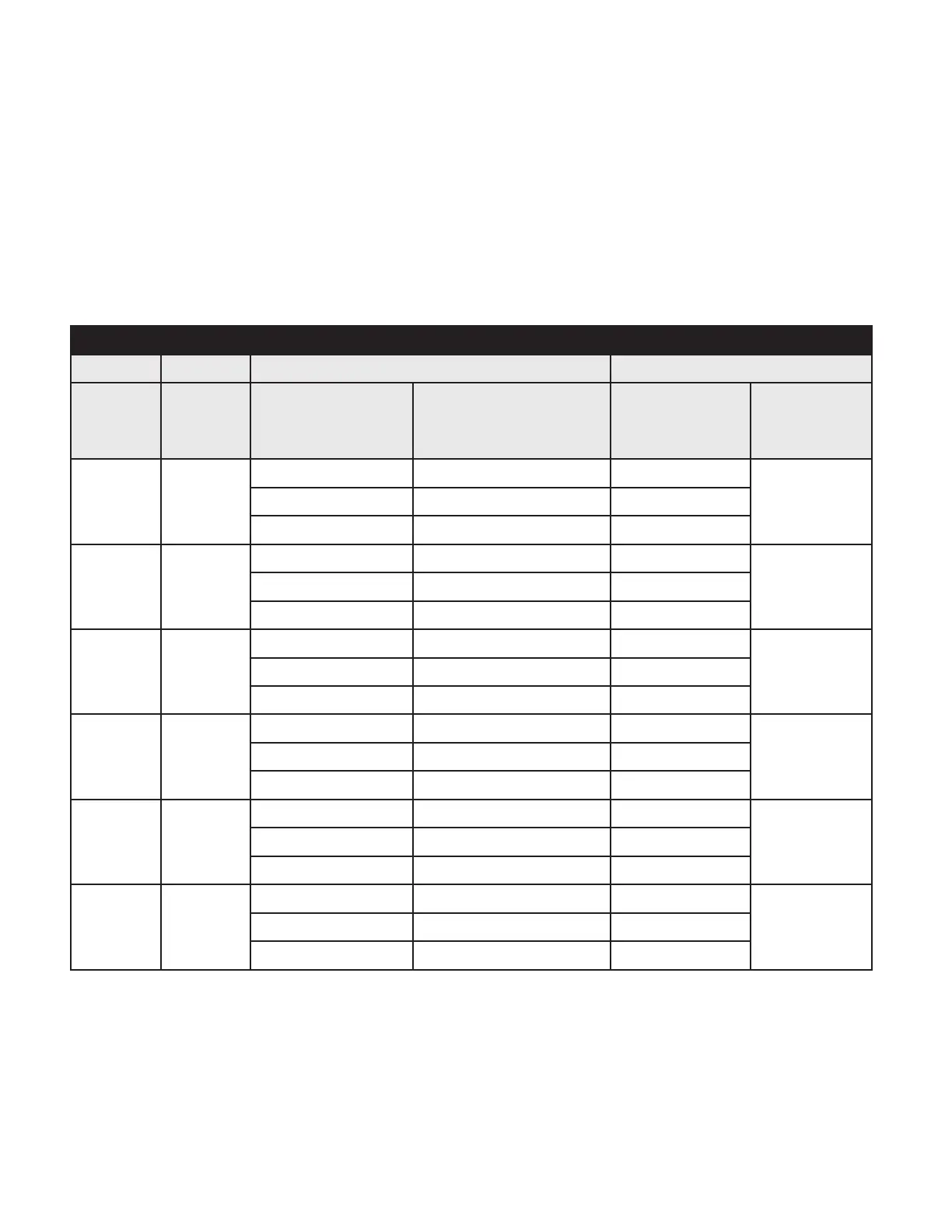

UNIT SIZING CHART

OIL GAS MAXIMUM EQUIVALENT FEET OF VENT PIPE

MAX*

OIL GPH

INPUT

MAX**

BTU/HR

INPUT

AT MAX BTU/HR

INPUT

AT 60% OF MAX BTU/HR

INPUT

VENTING WITH

VENT PIPE SIZE

MODEL

N/A 70,000

21 80 3"

SWG–350 100 4"

--- --- ---

1.10 170,000

--- 23 3"

SWG–4HD

SWG–4s

35 100 4"

65 100 5"

1.85 290,000

16 44 4"

SWG–5

SWG–5s

51 100 5"

95 100 6"

2.65 416,000

28 78 5"

SWG–6

SWG–6s

68 100 6"

100 100 7"

3.60 566,000

28 78 6"

SWG–761 100 7"

90 100 8"

4.75 740,000

26 72 7"

SWG–851 100 8"

70 100 9"

8. Air ow adjustment MUST be made to ensure appliance e ciency. This should be done at the appliance

exhaust outlet with a velocity meter, draft gauge, or by "match test procedure". A match test is in accordance

with National Fuel Gas Code ANSI Z223.1, Section 8.6.

9. On oil- red and gas- red heating appliances not equipped with a draft hood, a barometric draft control MUST

be installed to regulate proper air ow and uctuations in the system’s air ow during operation. Fluctuations

may come from wind loads on the outlet of the power venter, house de-pressurization during windy days,

and the di erent house ventilation requirements between summer and winter operation. For gas appliances,

use a Field Controls Type MG-1 Barometric Draft Control. For oil appliances, use a Field Controls Type M or RC

Barometric Draft Control. Gas- red draft induced systems should have a single-acting barometric draft control

installed.

Table 1

*Rating at 100 psi. Sizing based on appliance maximum input rate not actual ring rate.

**Do not exceed maximum BTU/HR input rating or maximum oil GPH input. For multiple venting system applications, add the input for

each appliance. Category I gas- red draft induced systems require an SWG-4HD or larger. Category III gas- red draft induced systems

require an SWG-5 or larger.

PROCEDURE FOR CALCULATING TOTAL EQUIVALENT PIPE LENGTH IN FEET

1. Calculate the total equivalent feet for each type of tting used in the venting system from Table 2.

2. Calculate the total amount of feet for the straight lengths of vent pipe.

3. Add the equivalent feet for the tting with the total amount of feet of straight lengths. This will

approximate the total equivalent feet of the vent system.

P/N 46139100 Rev P 08/19

Loading...

Loading...