page 7 of 12

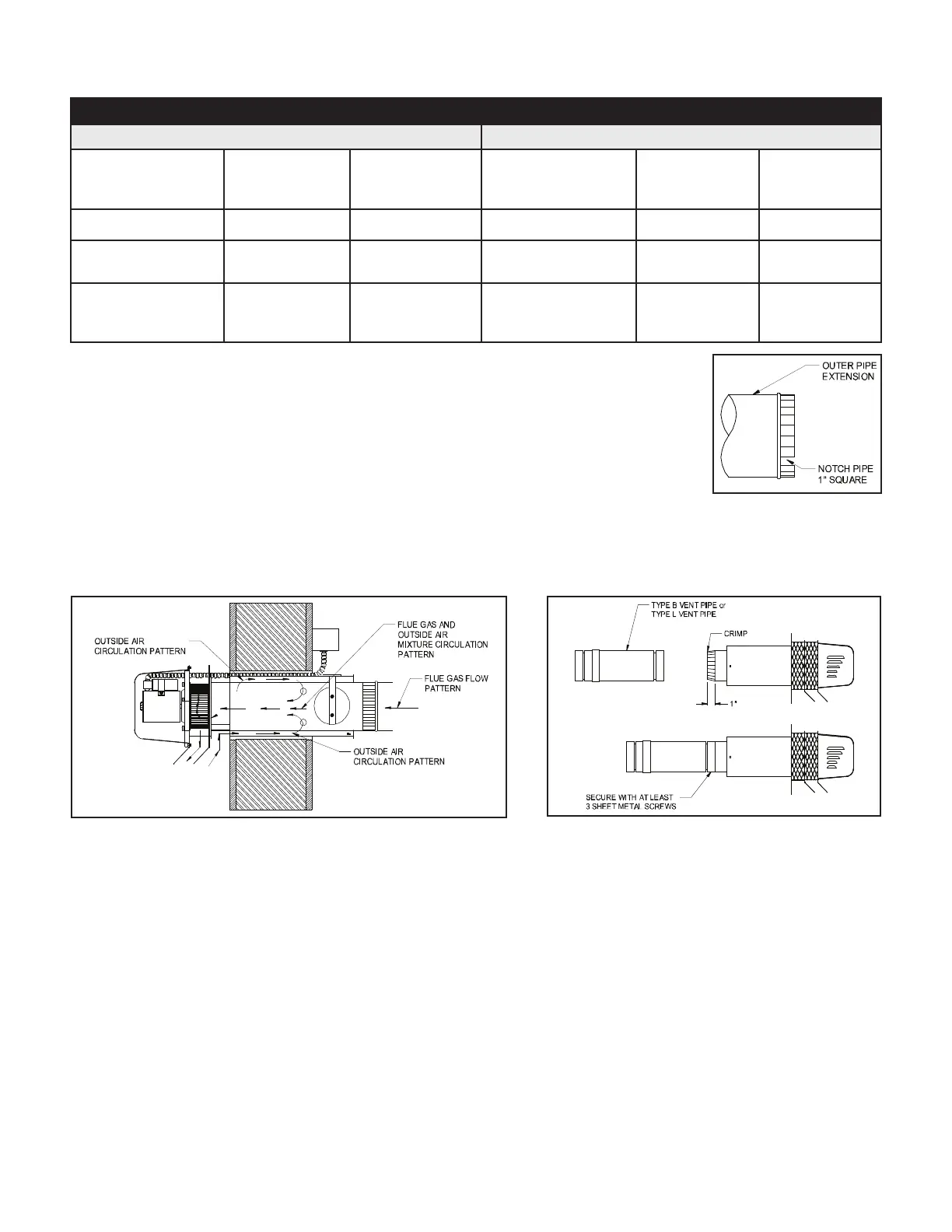

Use a PEK series extension kit or follow installation method below for a double

pipe system. To install an outer pipe extension to the SWG power venter, the end

pipe cover on the power venter must be removed. Then, cut a 1 inch square notch

into the vent pipe extension before attaching the power venter. (See Figure 5) This

allows clearance for the adjustment damper. Install the needed pipe extensions and

terminate the outer pipe extension with the end pipe cover. (See Diagram B) The

table above shows minimum allowable clearances when using single or double pipe

systems. When the outer pipe is extended over the inner pipe, use the double pipe

guidelines when determining clearances. Figure 6 shows how the air ow pattern

through an SWG reduces the required clearances to combustibles.

NOTE: Vent pipe joints should be secured with at least three (3) sheet metal screws.

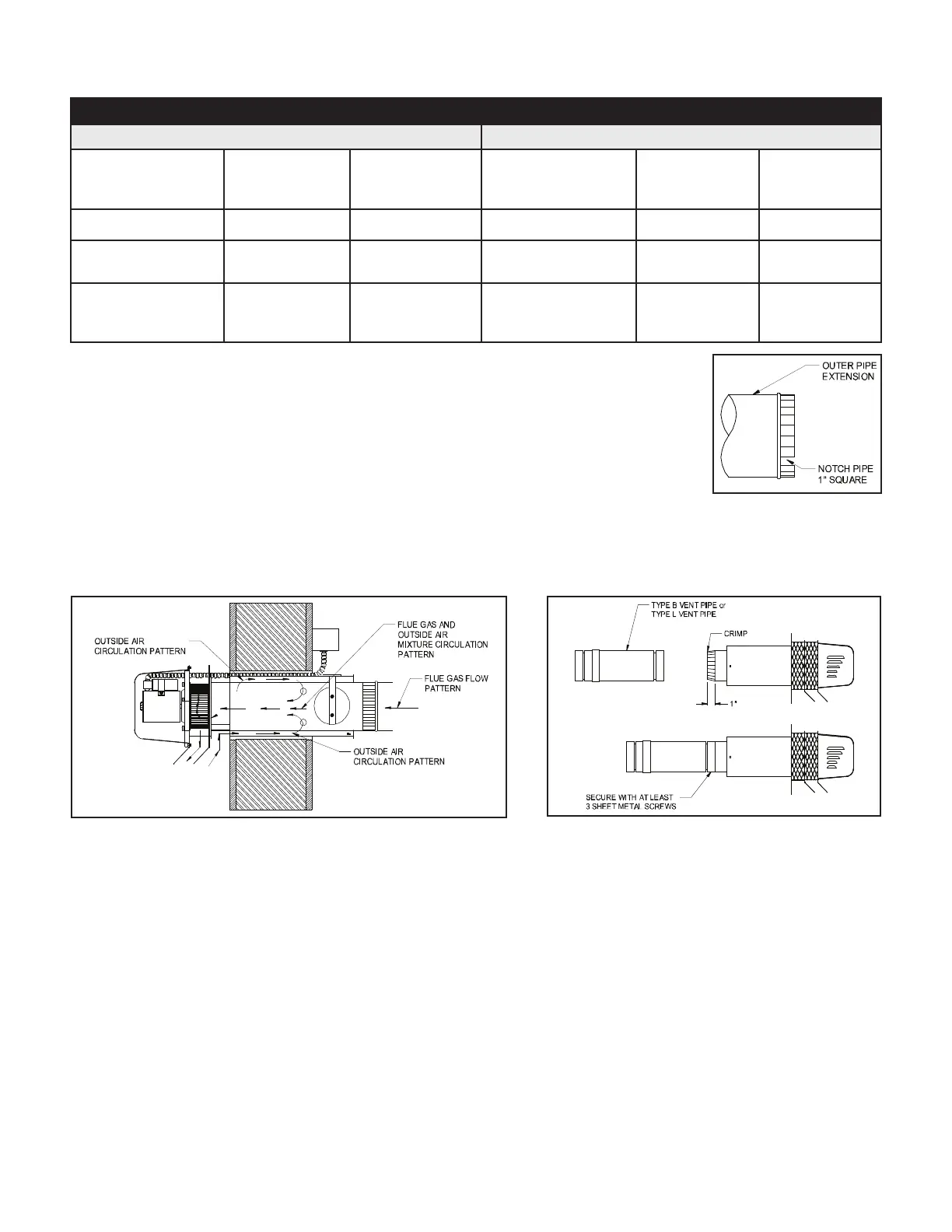

CLASS B AND CLASS L DOUBLE WALL VENT PIPE INSTALLATION

(Follow vent pipe manufacturer's listed or recommended clearances from combustible material.)

1. Using a hand crimper or a like device, crimp the inner pipe of the SWG power venter approximately 1"

long. (See Figure 7)

2. Attach the vent pipe over the crimped end of the SWG power venter inner pipe.

3. Secure the vent pipe to the SWG power venter inner pipe with at least three (3) #8 sheet metal screws.

Pre-drilling the holes through both pipes will allow easier fastening.

WIRING

NOTE: Refer to appropriate control kit for proper installation instructions.

Wire the power venter motor and controls in accordance with the National Electrical Code and applicable

local codes. UNIT MUST BE GROUNDED. Check ground circuit to make certain that the unit has been properly

grounded. The wiring should be protected by an over-current circuit device rated at 15 amperes. CAUTION MUST

be taken to ensure that the wiring does not come in contact with any heat source. All line voltage and safety

control circuits between the power venter and the appliance MUST be wired in accordance with the National

Electrical Code for class 1 wiring or equivalent.

INSTALLATION CLEARANCE WITH SINGLE WALL VENT PIPE

DOUBLE PIPE SYSTEM SINGLE PIPE SYSTEM

Allowable inlet

temperature SWG

Stainless Steel

Allowable inlet

temperature

SWG

Clearance

(A)

Allowable inlet

temperature SWG

Stainless Steel

Allowable inlet

temperature

SWG

Clearance

(B)

400ºF or less 400ºF or less

1

⁄2" minimum 400ºF or less 400ºF or less 3" minimum

400ºF to

650ºF US/575ºF CA

400ºF to 550ºF 1" minimum

400ºF to

650ºF US/575ºF CA

400ºF to 550ºF 4" minimum

400ºF to

650ºF US/575ºF CA

400ºF to 550ºF

1

⁄2" minimum with

sheet metal liner

400ºF to

650ºF US/575ºF CA

400ºF to 550ºF

3" minimum

with sheet

metal liner

Figure 6

Figure 7

Figure 5

INSTALLATION USING SINGLE WALL VENT PIPE

Table 3

P/N 46139100 Rev P 08/19

Loading...

Loading...