page 9 of 12

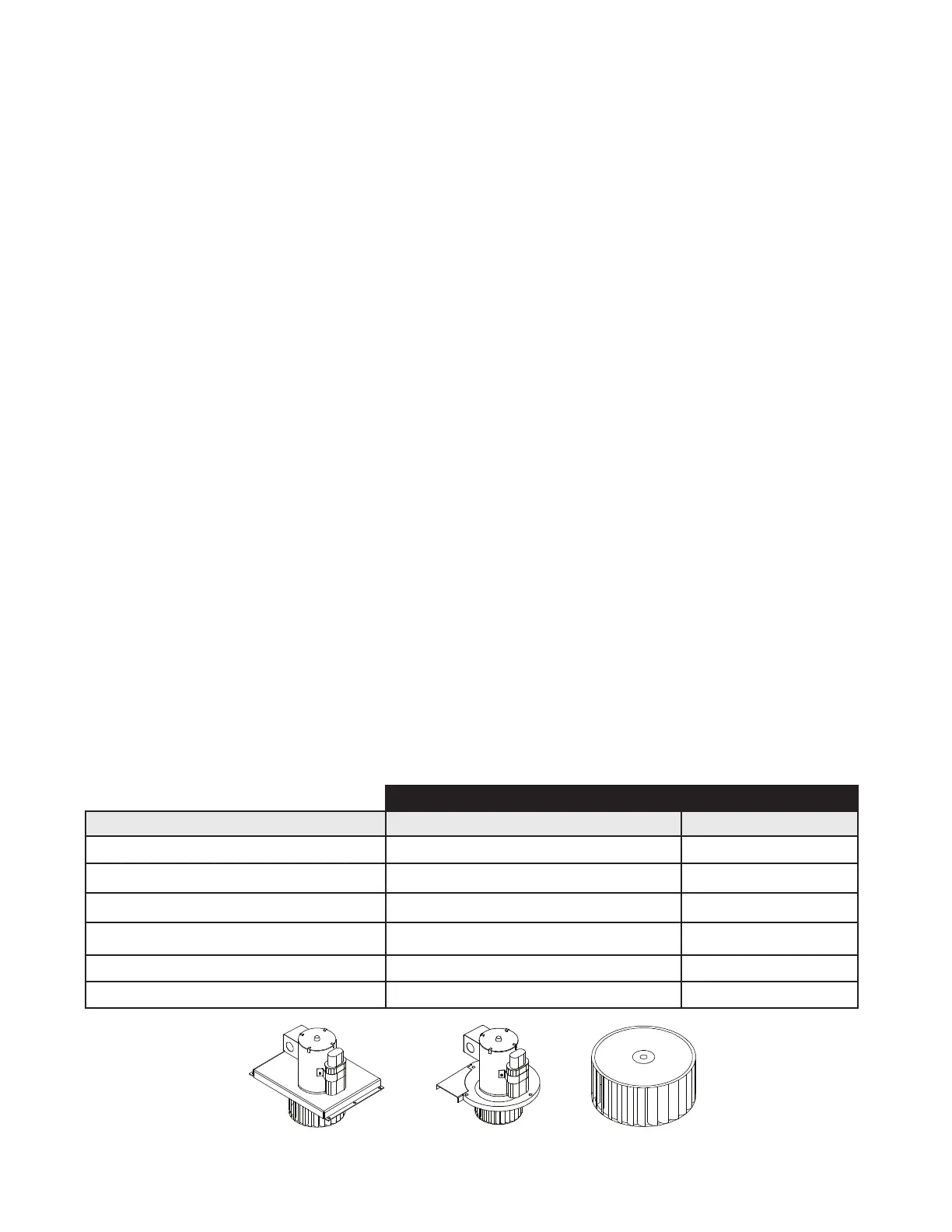

PART NUMBERS

MODEL REPAIR MOTOR ASSEMBLY BLOWER WHEEL

SWG–3 46196601 46131800

SWG–4HD, SWG–4s 46234800 46310400

SWG–5, SWG–5s 46234900 46213800

SWG–6, SWG–6s 46235000 46385800

SWG–7 46152401 46154700

SWG–8 46460101 46154800

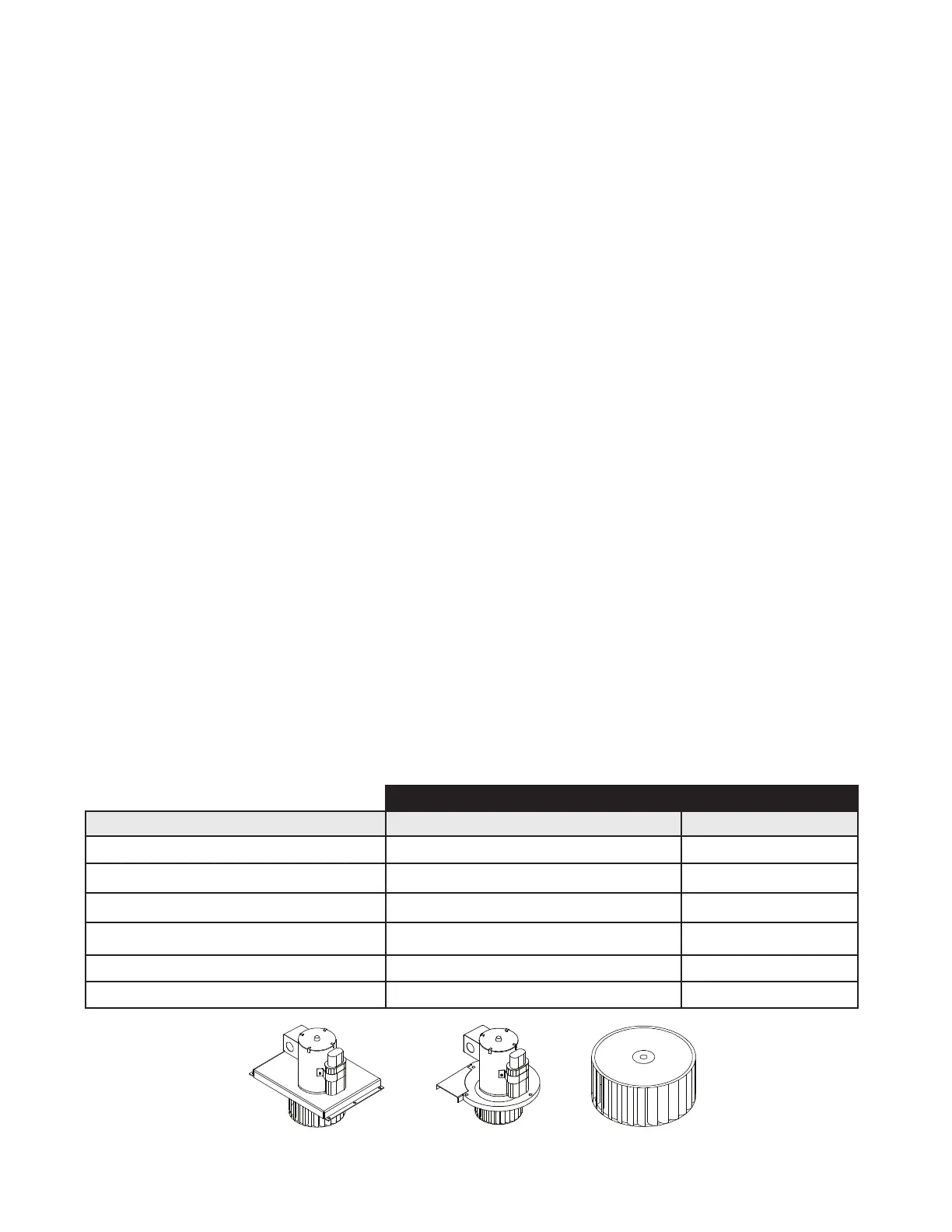

SWG Repair

Motor Assembly

SWG Repair

Motor Assembly

Blower

Wheel

MAINTENANCE

1. Motor: Inspect the motor once a year - motor should rotate freely. To prolong the life of the motor, it must

be lubricated with six drops of SWG Superlube, Part # 46226200, annually.

2. Wheel: Inspect the power venter wheel annually to clear any soot, ash or coating which inhibits either

rotation or air ow. Remove all foreign materials before operating.

3. Vent System: Inspect all vent connections annually for looseness, for evidence of corrosion and for ue

gas leakage. Replace, seal or tighten pipe connections if necessary. Check the power venter choke plate

to ensure it is secured in place. Check the barometric draft control, if installed, to ensure the gate

swings freely.

4. System Safety Devices: With the heating system operating, disconnect the pressure sensing tube from

the pressure switch on the CK Kit. This will stop the burner operation. Re-connecting the tube will relight

the burner. For 30 millivolt operating systems, disconnect one lead of the spill switch circuit from the

thermocouple junction block. This will shut o the pilot and the burner. Re-connection will allow relighting

the pilot.

REPLACEMENT PARTS

Should the motor or blower wheel need replacing, the following replacement items are available. The Repair

Motor Assembly contains the Motor and Blower Wheel factory assembled to a mounting bracket.

Table 4

5. Visually determine that the main burner is burning properly; i.e., no oating, lifting or ashbacks. When

performing smoke test on oil- red systems, the burner should operate at a zero to a trace smoke. This can

indicate reduced available combustion air to burner.

6. If appliances are equipped with high and low ame control or ame modulation, check for proper main

burner operation at low ame.

7. Test for spillage at draft hood or barometric draft control opening and burner inlet air location after 5

minutes of main burner operation. Use a draft gauge, ame of a match or candle, smoke from a cigarette,

cigar or pipe. If spillage occurs, adequate air is not available. Shut o heating appliance thermostat and

check for spillage around the draft hood, barometric draft control or burner inlet air location after power

venter has stopped operation. If a ow reversal is noticed, house de-pressurization is occurring and make up

air is required. For oil- red systems, this may be noticed by oil fume smell after post purge cycle.

8. Turn on all fuel burning appliances within the same room so that they will operate at their maximum input.

Then repeat Steps 5 through 7.

9. Return doors, windows, exhaust fans, replace dampers and any other fuel-burning appliances to their

previous condition of use.

P/N 46139100 Rev P 08/19

Loading...

Loading...