4

3

a) Disc leveling: - To eliminate uneven penetration and side draft, leveling is

done by means of top link.

4. Don’t allow anyone to come across the disc ridger.

6. Lift the disc ridger before approaching the road.

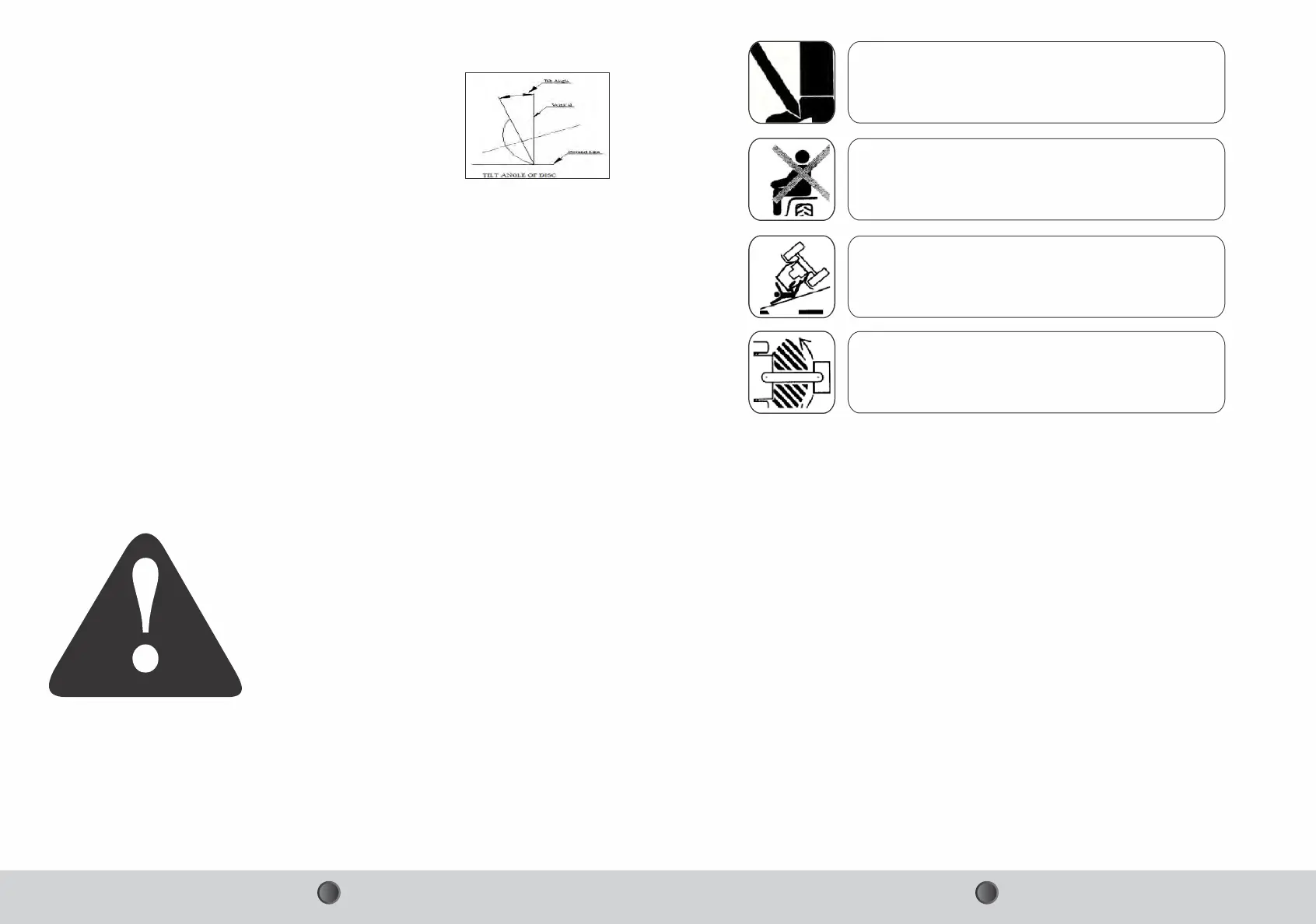

b) Tilt Angle is the angle which the plain of the cutting

edge makes with the vertical line. Its ranges lie

between 150 - 250. Increasing the tilt angle improves

disc penetration in heavy, sticky soils. Decreasing the

tilt angle improves disc penetration in loose and brittle

soils.

c) Depth control:-

The depth at which the implement is required to work is controlled hydraulically

by raising or lowering the control lever on the tractor.

1. Before you start working, Please check all nuts & bolts of the disc ridger.

3.3 WARNING FOR THE DRIVER

2. Be vigilant about the tree roots and stones. Don’t work on stony soil.

3. Tractor should be in first high or fourth low gear.

5. Lift the disc ridger during turning.

3.4 SAFETY

Understanding the Machine Safety Labels

The machine safety labels shown in this section are

placed in important areas on your machine to draw

attention to potential safety hazards.

The operator’s manual also explains any potential

safety hazards whenever necessary.

On your machine the words DANGER WARNING and

CAUTION are used with this safety-alert symbol.

DANGER identifies the most serious hazards.

† Before ploughing with disc ridger take care that nobody stands near it.

Safety-Alert Symbol

Never allow riders on the tractor or implement

unless an additional seat is available.

Be careful when moving around steep gradient to

avoid sharp turn.

Never transport the implement on rough roads

during the night. When operating, avoid sharp

turns that may cause tractor colliding with the

implement.

In order to protect yourself always wear adequate

clothes and shoes during the operations.

4.1 MAINTENANCE INSTRUCTIONS

4. MAINTENANCE

If you work with the disc ridger on stony land, maintenance also increases. Please

follow these rules to get the best results.

1. If the soil has entered the grease nipple, then change the nipple.

2. If disc ridger is new after initial working of first two hours, tighten all nuts & bolts.

3. After every fifty hours grease all greasing points with grease gun and tighten all

nuts & bolts.

4. After every fifty hours, open the bearing hub of disc ridger & cleanse with diesel

oil & pump in new grease.

2. Replace the worn out nuts & bolts.

3. If disc ridger has to remain unused for long time then clean it & apply a layer of

used oil for rust prevention.

4.2 STORAGE OF MACHINE AFTER WORK

These steps will enhance the life of your disc ridger.

1. Wash the disc ridger after work.

Loading...

Loading...