13 15 1814 1716

19 21 2420 2322

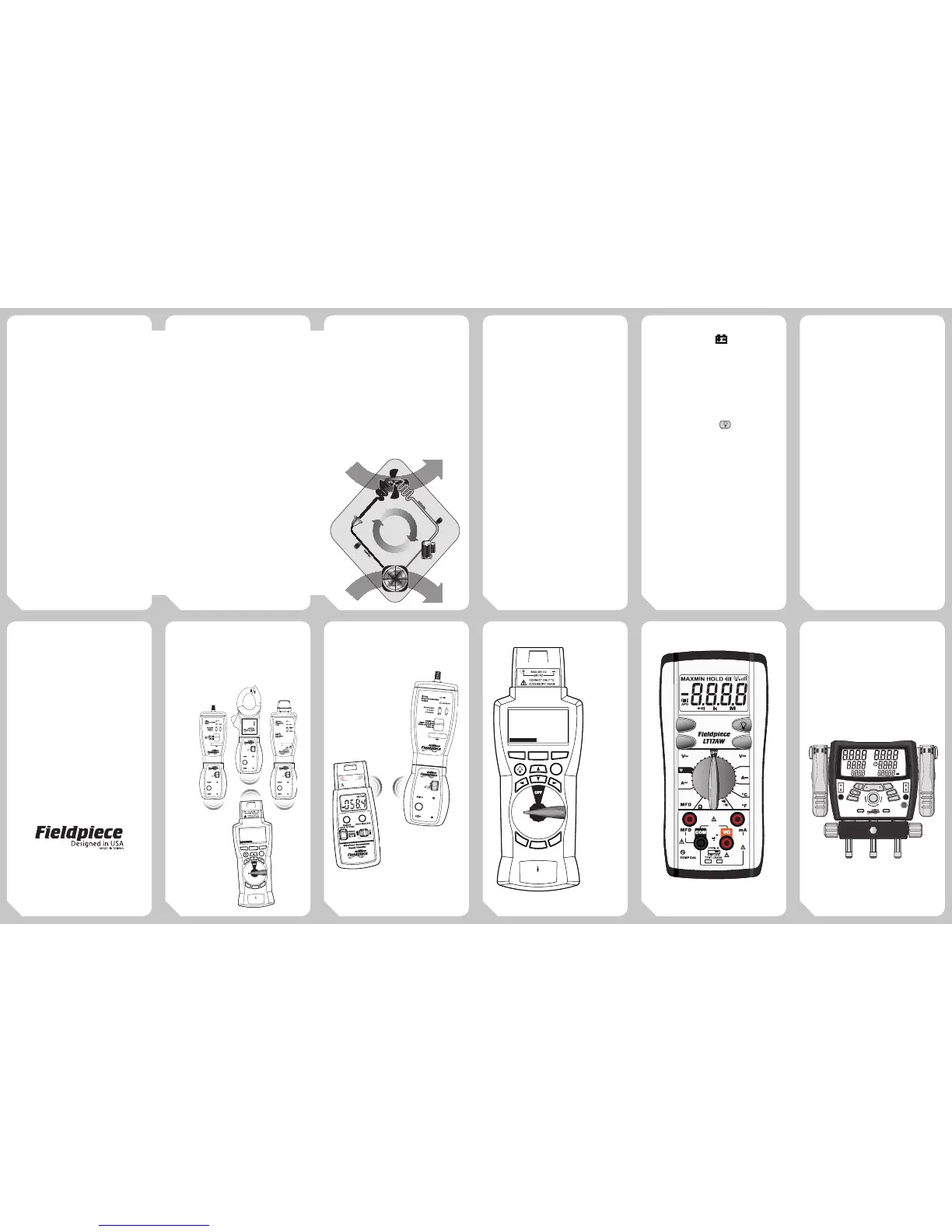

A/C Basics

The Evaporator, Condenser,

Restrictor (Throttling valve) and

Compressor are the four basic

components of an air conditioner.

Following one pound of refrigerant

through the system shows the

function of each component.

Subcooled liquid refrigerant at high

pressure enters the restrictor and is

throttled to saturated refrigerant at a

lower pressure. The restrictor can be

of either a xed or TXV/EXV type. The

xed type must be charged to a target

superheat that varies with indoor and

outdoor conditions. TXV/EXV systems

must be charged to subcooling.

The evaporator capacity varies

with the indoor heat load on a xed

restrictor. The TXV/EXV regulates the

size of the restriction to maintain a

constant superheat. This essentially

adjusts the capacity of the evaporator

responding to the indoor heat load.

After the restrictor, refrigerant enters

the evaporator at a low temperature

and pressure and boils (evaporates)

condenses back into a liquid. Once

all of the gas is condensed into a

liquid, additional removal of heat

causes a temperature drop that

is known as subcooling. TXV/EXV

systems are charged to subcooling

since superheat is controlled by

the throttle valve. Subcooling

measurements are taken on the

liquid line between the condenser

and TXV/EXV. Finally, the subcooled

liquid enters the restrictor and the

cycle starts again.

Maintenance

Clean the exterior with a dry cloth.

Do not use liquid.

Sensor Care

When not in use it is best to protect

this sensors with the vinyl slip cover

included with the SRH3.

Extreme conditions or exposure to

solvent vapors may oset the RH%

sensor. If this happens, place the

sensor in a controlled envrionment of

75%RH and between 68°F - 86°F for a

period of 24 hours.

To create a 75%RH environment

moisten a small amout of table salt,

in an open container such as a clean

2 liter bottle cap.

Place the container with the salt

solution and the SRH3 probe in a

sealable plastic bag, and leave the bag

in a room temperature location where

it will not be disturbed for 24 hours.

Note: It is important that the salt

solution does not come in direct

contact with the sensor, as this may

permenantly damage the sensor.

Battery ReplacementWhen

the meter displays the battery

should be replaced. Turn your SRH3

o and replace with 9V battery.

Auto Power O

Your SRH3 powers o automatically

after approximately 15 minutes to

lengthen battery life. To disable

"Auto O," hold the button while

powering on your SRH3. When

disabled, APO will not display in upper

left of LCD.

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject

to verication of the defect.

This warranty does not apply

to defects resulting from abuse,

neglect, accident, unauthorized

repair, alteration, or unreasonable use

of the instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

including but not limited to implied

warranties of merchantability and

tness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

State laws vary. The above

limitations or exclusions may not

apply to you.

For Service

In the USA, call Fieldpiece

Instruments for one-price-x-all out of

warranty service pricing. Send check or

money order for the amount quoted.

Send the meter freight prepaid to

Fieldpiece Instruments. Send proof

of date and location of purchase for

in-warranty service. The meter will be

repaired or replaced, at the option of

Fieldpiece, and returned via least cost

transportation. Outside of the USA,

please visit www.eldpiece.com for

service contact information.

www.fieldpiece.com

© Fieldpiece Instruments, Inc 2011; v05

Wireless Solutions

from Fieldpiece

into a gas by absorbing heat from the

indoor air. The refrigerant stays at the

same temperature and pressure until

all the refrigerant evaporates into a

gas. After the refrigerant becomes a

gas, it will continue to absorb heat

and become superheated at which

point its temperature will change. The

Superheat measurement is the best

indication of refrigerant charge level

in a fixed restrictor system. A TXV/

EXV system will keep the superheat

constant. There must be superheat

present to ensure liquid does not

ood the compressor.

Superheat measurements are taken

on the suction line between the

evaporator and compressor.

The compressor takes this low

temperature, low pressure, slightly

superheated refrigerant and

compresses it to a much higher

temperature and pressure.

The highly superheated gas enters

the condenser and rejects heat

into the outside air. The refrigerant

EVAPORATOR

CONDENSER

THROTTLE

VALVE

COMPRESSOR

REFRIGERANT

FLOW

H

i

g

h

P

r

e

s

s

u

r

e

S

i

d

e

L

o

w

P

r

e

s

s

u

r

e

S

i

d

e

RETURN AIR SUPPLY AIR

OUTDOOR AIR HOT AIR

Loading...

Loading...