1

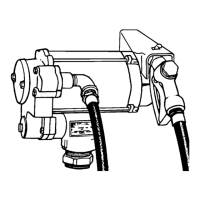

SERIES FR702VR

115 and 230 VOLT AC

FUEL TRANSFER PUMP

Owner’s Operation & Safety Manual

Models FR702VR & FR702VER

OUTSTANDING FEATURES

•Up to 18 GPM/68 LPM

•UL listed dispenser & motor

•Full 1/3 HP explosion proof motor

•Meter accuracy

of ±

1%

GENERAL DESCRIPTION

The FR702VR compact cabinet pump is based on Fill-Rite’s

FR700V positive displacement, direct drive pump, and Fill-Rite’s

series 800C nutating disc flow meter which features a flow rate of 5

to 20 GPM or 19 to 76 LPM and is accurate to within ± 1%.

Depending on product viscosity and nozzle selection, the FR702VR

can deliver up to 18 gallons/68 liters of fluid per minute. This

pumping system is UL listed for use with gasoline and diesel fuel.

The U.S. gallon meter has three resettable wheels, two unit wheels

and a tenth wheel. Its non-resettable totalizer has five unit wheels

and a tenth wheel. The optional liter meter has three unit wheels

which can be reset to zero. Its non-resettable totalizer has six unit

wheels.

OPTIONS

• Automatic nozzles

• Metering in U.S.

gallons or liters

•

Red or

white cabinet paint

• Pedestal for island installations

•

220 VAC, 50/60

Hz

TECHNICAL INFORMATION

Design Features:

• 1.25" NPT inlet, 3/4" NPT outlet

• 22 PSI maximum outlet pressure

• Minimum dry vacuum of 10" Hg

• Furnished with 3/4" dia. x 12' hose and manual nozzle

•

Cabinet measures 13"W x 11.5"D x 17.5"H (38 x 29 x

43.6 cm)

•

Built-in check valve, bypass valve and thermal exp

ansion

valve

•

No additional foot valve or check

valve needed to hold

prime

•

1/3 HP 115VAC-60Hz, 5.5 amp, 1725 RPM, direct

drive

motor

•

Ball bearing construction: no lubrication required

• Thermal overload protection

•

Explosion

proof

•

Meter’s mechanical totalizer to 100,000 units

•

Meter accuracy is ± 1%

• Unit wheels have large 11/16" (18 mm) figures

• Convenient, large reset knob with positive zero stop

• Not for

resale use

• Pre-installed Anti-Siphon Valve

FLUID COMPATIBILITY

If in doubt about compatibility of a specific fluid, contact supplier of

fluid to check for any adverse reactions to the wetted materials in

the parts list.

SAFETY INSTRUCTIONS

To ensure safe and efficient operation, it is essential to read and

follow each of these warnings and precautions.

1.

Improper use or installation of this product can caus

e serious

bodily

injury or death.

2.

Do NOT smoke near pump or use pump near an

open flame

w

hen pumping flammable fluids. Fire could result.

3.

A Fill-Rite filter should be used on pump outlet to en

sure that

no foreign mate

rial is transferred to

fuel tank.

4.

Use gasoline and oil resistant thread sealant or se

alant tape

on all threaded jo

ints to protect ag

ainst leakage.

5.

Storage tank should be anchored to prevent tipping

in both the

full and empt

y co

nditions.

6.

To minimize static electricity buildup, only use static wi

re,

conductive hose w

hen pumping fl

ammable fluids and keep

nozzle in contact

with container being filled wh

ile filling

container.

7.

The pump motor is equipped with thermal overload

protection.

If overheated, it

will shut off without any damage to

the

w

indings. Be sure to turn off the pump powe

r if this occurs.

When the moto

r cools, it will restart without warnin

g if power is

on.

8.

Take motors needing service to an authorized repa

ir shop to

maintain “explosion proof

” and “rain proof” integrity.

9.

Do not operate without the check valve (700F2661

) in place.

Fluid leakage could result.

DANGER

Electrical wiring should be done by a licensed electrician in

compliance with local, state and national electric codes,

NEC/ANSI/NFPA 70, NFPA 30, NFPA 30A, as appropriate to the

intended use of the pump. Threaded rigid conduit, seal fittings and

conductor seal should be used. Pump should be properly grounded.

Improper use or installation of this product can cause serious bodily

injury or death.

WARNING

Do not use this product for fluid transfer into aircraft. This product is

not suited for use with fluids for human consumption or fluids

containing water.

INSTALLATION

GENERAL

Pumps are furnished with a tank adapter for skid tank mounting;

pedestals are available for island installations. All tanks must be

properly vented. A pressure retaining vent/fill cap can be used to

reduce fuel loss due to evaporation but will reduce flow rate.

Fill-Rite filters are recommended when pumping fuels.

Pump has a built-in check valve with pressure relief to prevent fluid

thermal expansion from causing unsafe system pressures. Do not

use additional check valves or foot valves unless they have a

proper pressure relief valve built into them. Additional check

valves will reduce flow rate.

Use a gasoline and oil resistant pipe sealant on all pipe threads to

protect against leaks.

SKID TANK MOUNTING

1. Cut a 1-1/4" pipe that will extend to at least 3" (8 cm) above

bottom of tank

when screwed into tank adapter and

tank

adapter is scre

wed into tank flang

e.

2.

Screw pipe into tank adapter, then screw tank ada

pter into

tank flange.

3.

Mount pump on tank adapter.