OPERATOR’S MANUAL

F3GST2TK

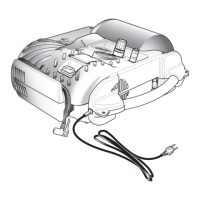

3 GALLON MINI STACK TANK PORTABLE AIR COMPRESSOR

F3GST2TK OM Ver. 07/12

3!6%4()3-!.5!,&/2&5452%2%&%2%.#%

9OURAIRCOMPRESSORHASBEENENGINEEREDANDMANUFACTUREDTO(USKYSHIGHSTANDARDFORDEPENDABILITYEASEOFOPERA

TIONANDOPERATORSAFETY7HENPROPERLYCAREDFORITWILLGIVEYOUYEARSOFRUGGEDTROUBLEFREEPERFORMANCE

7!2.).'4OREDUCETHERISKOFINJURYTHEUSERMUSTREADANDUNDERSTANDTHEOPERATORSMANUALBEFOREUSING

THISPRODUCT

4HANKYOUFORBUYINGA(USKYPRODUCT

CUSTOMER SERVICE

1-866-242-4298

FOR ASSISTANCE IN CANADA

PLEASE CALL

1-803-980-6570

Thank you for buying a FINI product.

Your air compressor has been engineered and manufactured to FINI’s high standard for dependability, ease of operation,

and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.