36

36

MEGA SD - Cod.197DD8100

GB

MAINTENANCE

•Correct maintenance is crucial to achieve maximum efficiency of your compressor, and to lengthen its operating life.

•It is also important to comply with the maintenance intervals recommended, but it must be remembered that such intervals

are suggested by the manufacturer in the event that the environmental conditions of use of the compressor are optimal (see

“Installation” chapter).

•The maintenance intervals can therefore be reduced depending on the environmental conditions in which the compressor

operates.

•The oil used is RotEnergy Plus, the use of a different oil does not guarantee perfect efficiency and compliance with the

maintenance intervals.

•The following pages describe the routine maintenance operations which can be performed by the person in charge of the

compressor, the non-routine maintenance operations must instead be performed by an authorised technical assistance

centre.

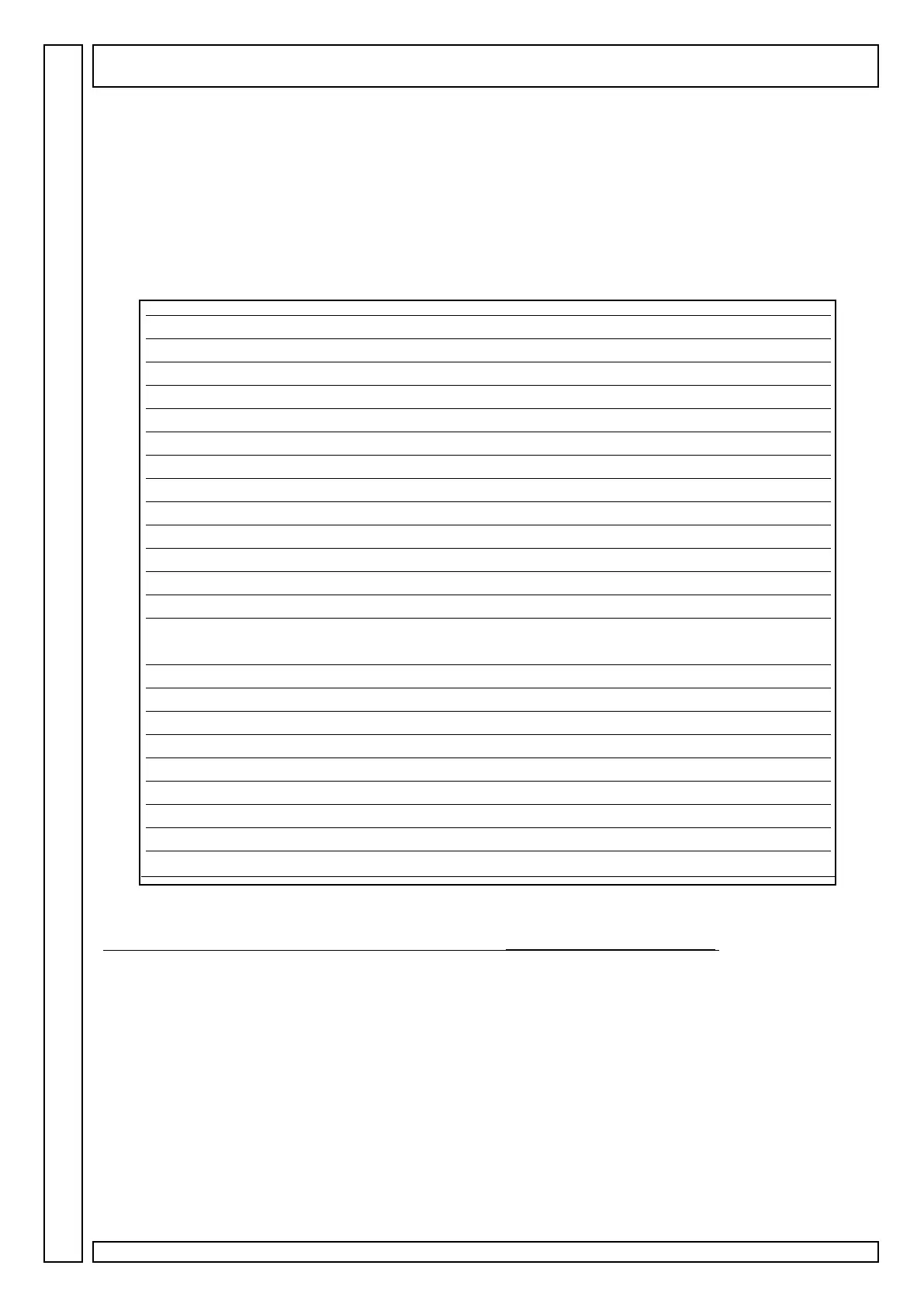

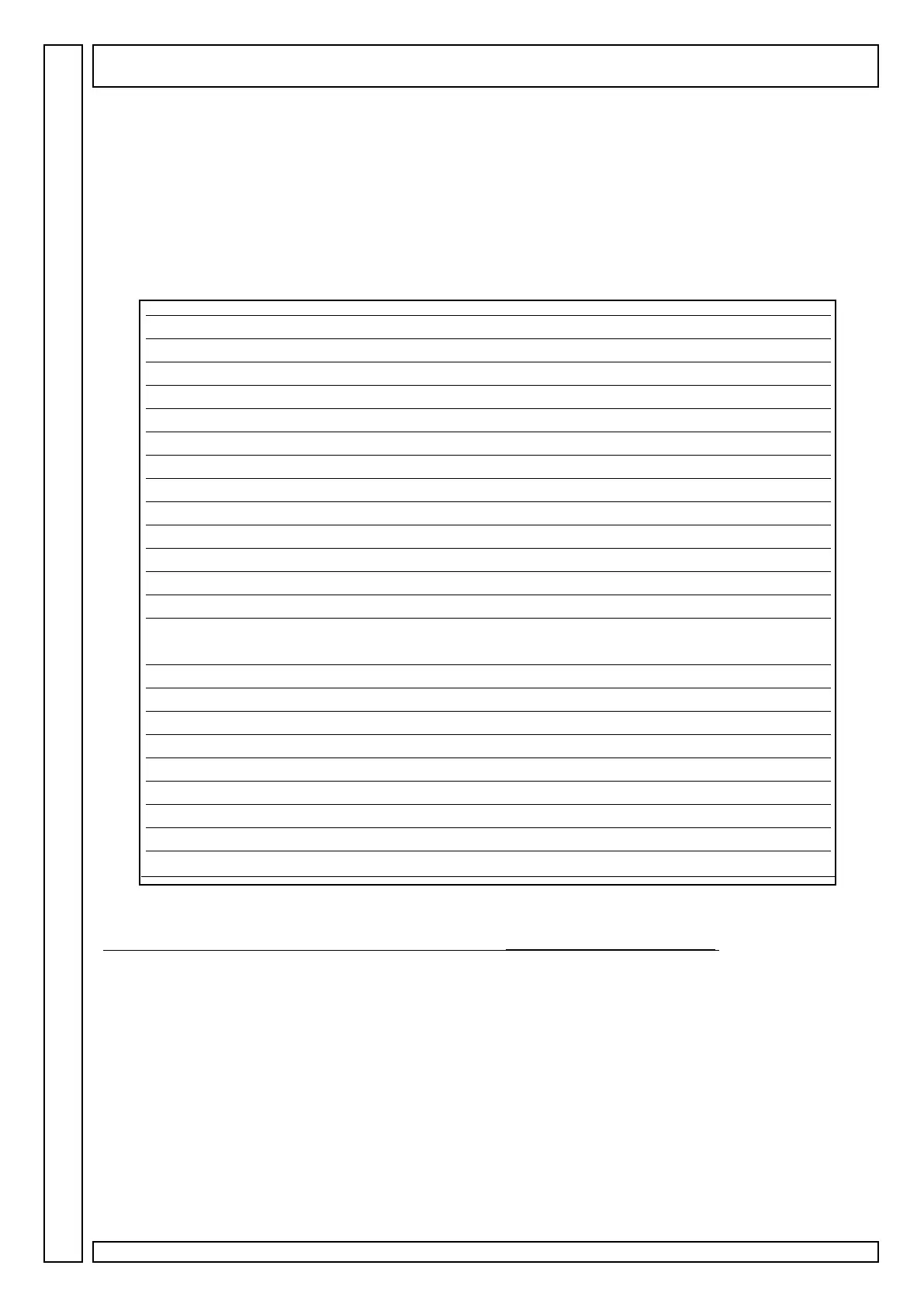

Maintenance table

If the hourly limit is not reached, the maintenance operations highlighted in bold must be performed at least once a year.

To verify correct machine operation, perform the followng checks after the first 100 hours of work:

1) Check the oil level: top up with the same type of oil if necessary.

2) Check for proper screw tightening: in particular the power electric connection screws.

3) Visually check that all fittings seal properly.

4) Check the belt tension and if necessary, reset it.

5) Check the hours of work and the type of service selected

6) Check room temperature.

BEFORE MAINTAINING THE MACHINE ALWAYS PERFORM THE FOLLOWING:

√ Press the machine automatic stop button (do not use the emergency button).

√ Power the machine off by means of the wall outer switch.

√ Close the line cock.

√ Make sure that no compressed air is inside the oil separator tank.

√ Remove fairing and/ or panels.

TYPE OF MAINTENANCE

MAINTENANCE SCHEDULE

work hours o at least

ORDINARY MAINTENANCE

Drain condensate

50 weekly

Clean cabinet pre-filter panel

50 weekly

Checking and topping up oil

500 once per month

Clean air intake filter cartridge 500 -

Check transmission belt tension

500 -

Check and clean radiator 1000 once a year

Grease motor bearings 3000 -

Replace primary intake air filter cartridge 2000 once a year

Replace secondary intake air filter cartridge 4000 once a year

Replace oil filter

4000* once a year

Replace oil separator filter

4000* once a year

Replace oil

4000* once a year

Replace scavenge non return valve

4000* once a year

EXTRAORDINARY MAINTENANCE

Intake valve service

8000

Minimum pressure valve service

8000

Solenoid valve replacement

12000

Electric motor bearings replacement

12000

Replace flexible hoses

12000

Replace drive belt

12000

Air-end service

20000

* When using mineral oils, intervals are reduced to 1500 hours or one year

Loading...

Loading...