Rotar Plus 20-25 Easytronic - Cod.197AA2702 - Edition 00 01/2004

11

GB

DRAINED OIL IS A POLLUTANT!

Dispose of according to the environmental protection rules in force.

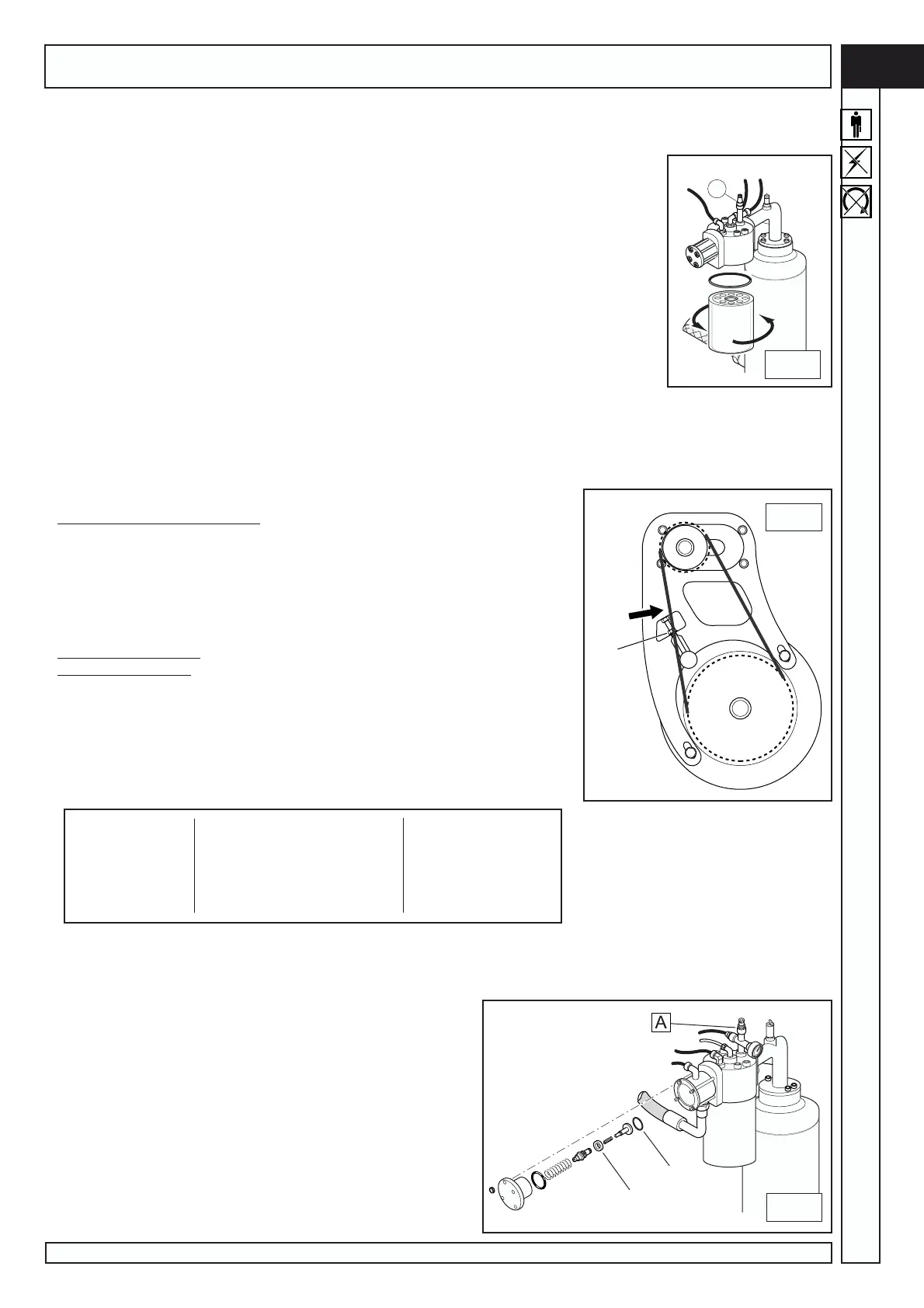

Change the oil separator filter (fig.10)

The oil separator is not washable and should be changed at each oil change. Never exceed 3000

operating hours.

Drain all compressed air through cock (A).

Unscrew the filter manually (use a special tool for filters, if needed). Rotate counter clockwise

to unscrew.

Fit a new filter. Screw new filter in clockwise. Smear the gasket of O-ring inside the oil separator

filter lightly with oil before fitting the filter.

Drain the condensate (fig.7)

Air/oil mixture cooling is set to occur below air dew point, however, it is impossible to avoid conden-

sate in oil totally.

Once a month, drain condensate before starting the compressor: open cock (C) and close it as

soon as oil start flowing out instead of water.

Always make sure the oil separator tank is depressurized before proceeding. Drain any

pressure through cock (A).

Check oil level and top up if needed.

CONDENSATE IS A POLLUTANT! Do not drain into the sewers. Dispose of according to the environmental protection rules in

force.

EVERY 2000 OPERATING HOURS

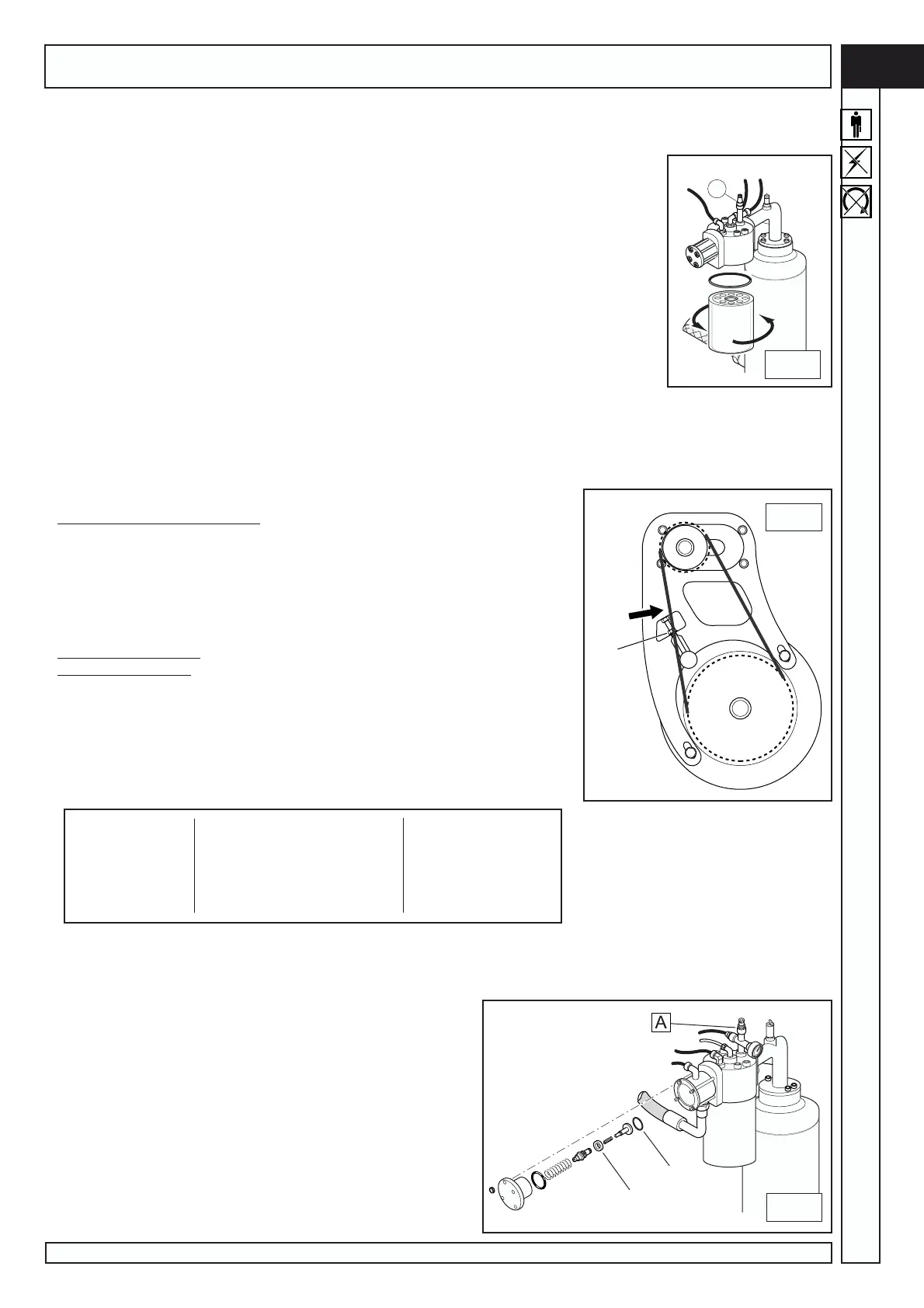

Check drive belt tension (Fig.12)

Use a frequency tester to carry out this check.

Proceed as follows:

Move tester microphone closer to the belt about at mid length and hit the belt

with a wrench.

Read value on tester. Stretch or slacken the belt if the value is different from

values indicated in the table:

Higher value = slacken

Lower value = stretch

To adjust, proceed as follows:

turn the screw (1) anti-clockwise to stretch the belt and clockwise to slacken.

check frequency value once again. Repeat the above procedure, if necessary, to

reach optimal value.

When finished, re-assemble cabinet parts before starting the compressor.

EVERY 12000 HOURS

Minimum pressure valve (fig.11)

Close the mains cock and drain all air from the oil separator tank

through valve (A)

Remove the flange fixing nuts and lift the flange

Change the seals (1) and (2).

Changing the hoses

Loosen the hose fittings, change hose and tighten fittings securely.

Proceed with the last steps of the oil change procedure.

Changing electric motor bearings.

This can also be done after 15,000 operating hours. Have wear

condition of bearings assessed by a specialized technician.

MAINTENANCE

A

10

12

1

2

11

Rotar Plus 20 2008 2010 2013 2008 2010

frequency (Hz) 71 73 68 72 71

Rotar Plus 25 2508 2510 2513 2508 2510

frequency (Hz) 79 78 75 81 77

V 400 / Hz 50 V 400 / Hz 60

Loading...

Loading...