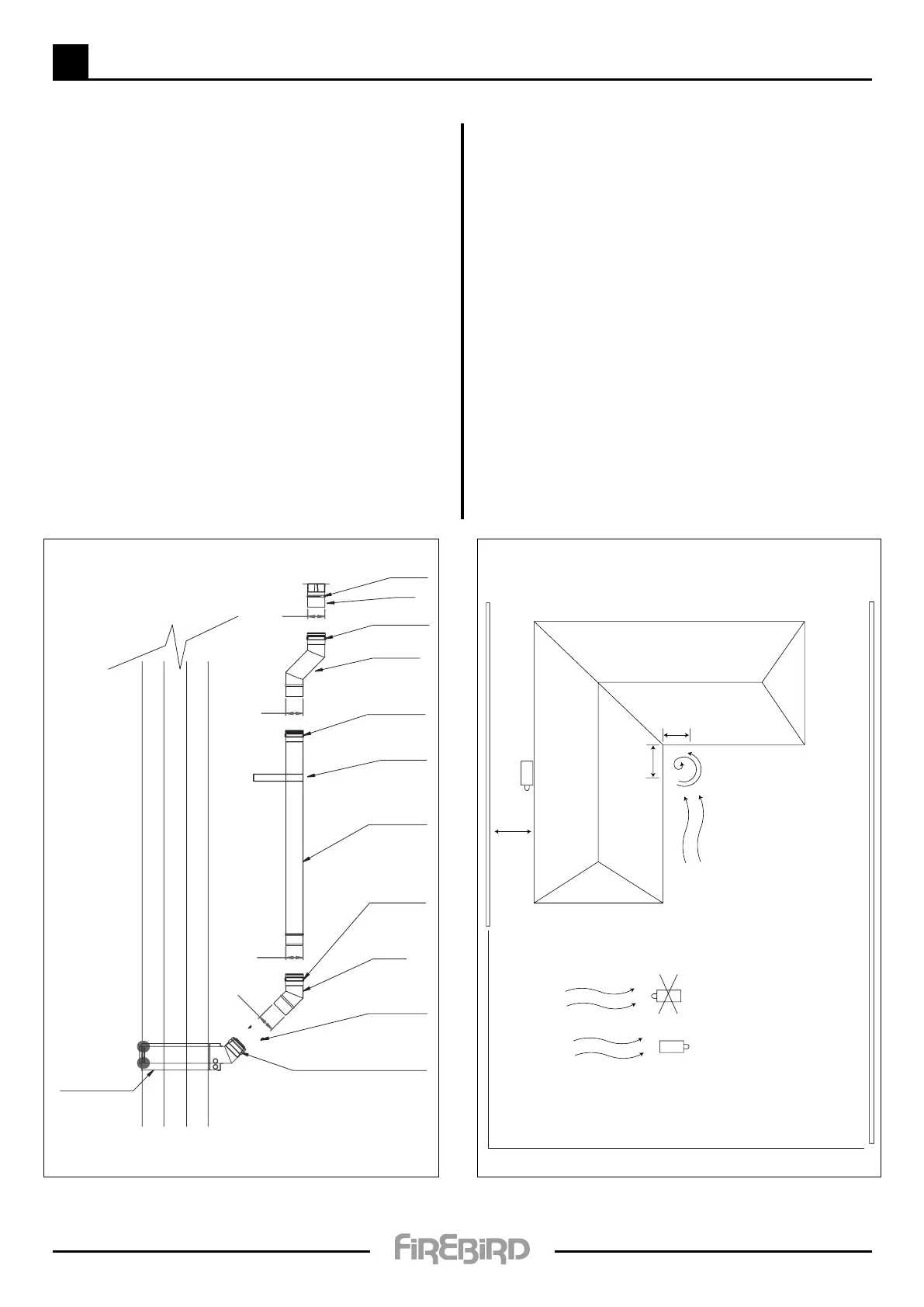

LOW LEVEL FLUES

Low level flues installed installed in a corridor/alley - if the

space is less than 3m, a plume kit must be considered.

Where there is high risk of funnelling winds. Should the

walls either side of the alley be high, again, a plume kit

should be considered.

Low level flues installed installed in open area/garden

- avoid facing the flue into the prevailing wind. The flue

should face away from prevailing winds.

Please refer to site location sketches for outline of points

above.A boiler that fails to operate correctly may require

a plume kit. This is because the flue gases are not able to

disperse, causing the photocell to become dirty.

3

3.4 STANDARDS & REGULATIONS - VENTILATION & COMBUSTION AIR REQUIREMENTS

ITEMS TO BE CHECKED IN ALL CASES

WHERE A BOILER IS OF CONCERN

There are four checks that must always be made where a

photocell has stopped a burner:

1. Ensure that the gasket door is sealed correctly to the

boiler.

2. Ensure that the burner collar is in place. If you see that

the burner collar and surrounding area is getting black,

this is highlighting that the boiler is experiencing down

draught and requires resecuring.

3. A common fault can be that the installer has not placed

the receiving nut for the burner on the boiler. If this nut

is missing, then the burner sits incorrectly on the boiler.

4. Ensure the flue is attached securely to the boiler, all

seals are in place and telescopic flues are not extended

beyond the maximum length.

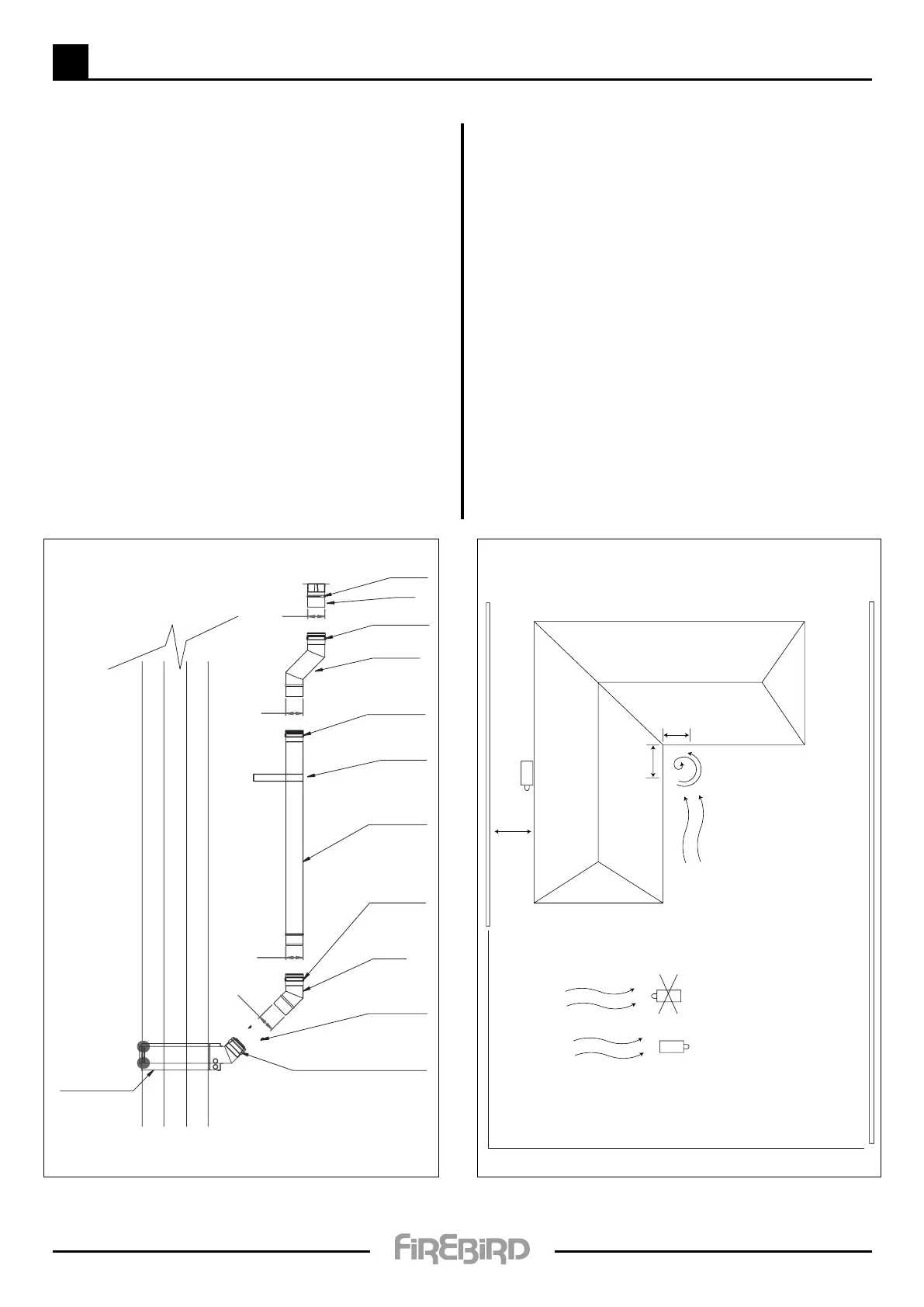

DIA

DIA

DIA

DIA

45˚ Bend

1000mm Length

Oset length

3 lip black seal

3 lip black seal

3 lip black seal

3 lip black seal

Cowl

Wire Mesh

Existing

Condensing

kit terminal

Remove Tapered Section

and insert 3 lip black seal

Wall Bracket

Plume Dispersal Kit for indoor boiler low level flue

Alley

<3m

Low Level & Heatpac in corridor/alley

Plume installed for <3m

Flue facing away from

prevailing wind

Prevailing

Wind

14

Loading...

Loading...