8 ©Firey AB (Oktober 2016)

Sensitivity Levels

— Model 660 (Table 1): Switch positions 3 and 4 adjust the sensitivity

to four dierent levels. Level 1 being the most sensitive to UV radiation

and the most susceptible to false alarms. Level 2 is the factory setting

and is recommended for most applications. The following are the logic

levels for the two switch positions:

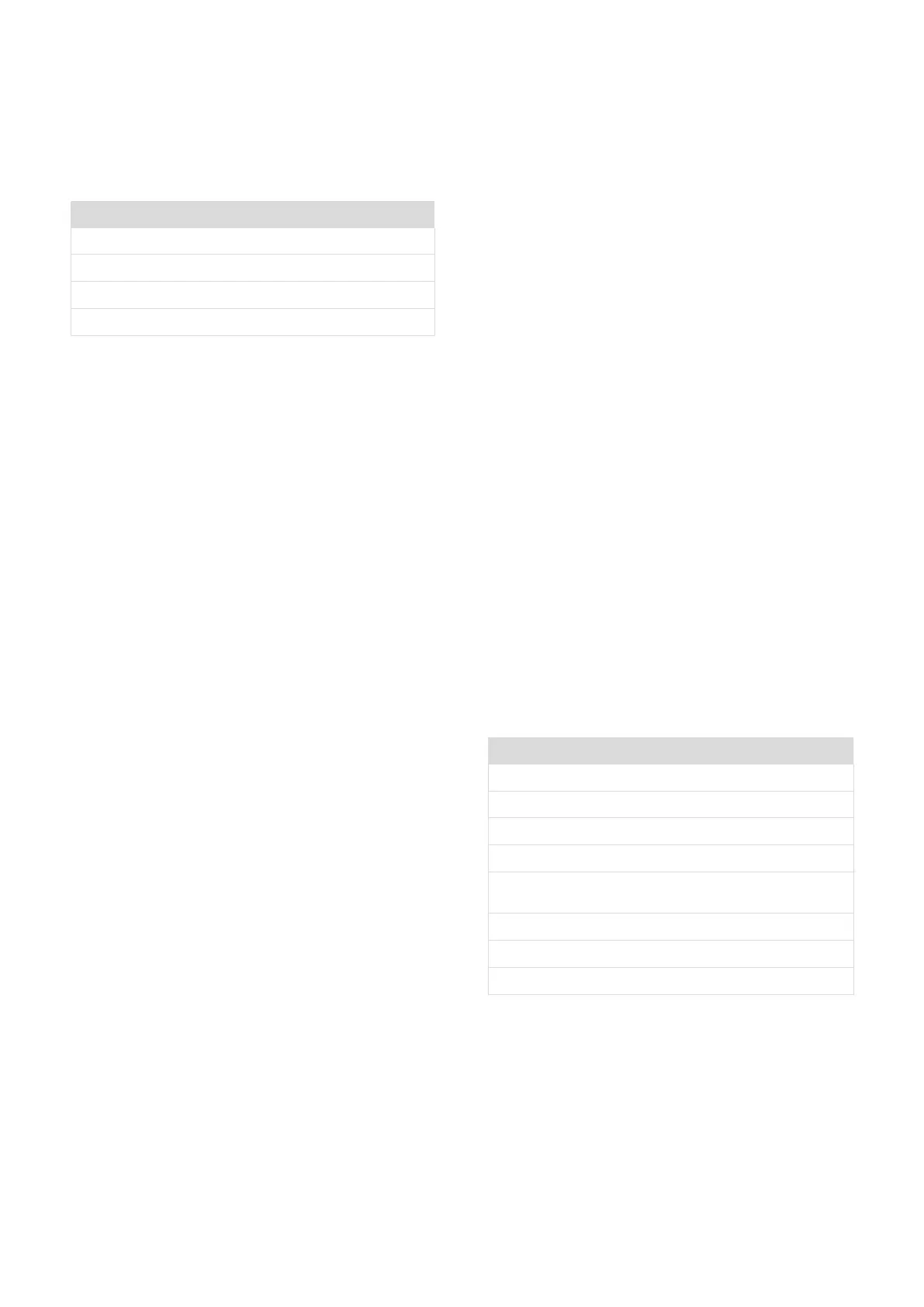

Table 1 – Model 660 Sensitivity Settings

Sensitivity Level Position 3 Position 4

1 (Max) O O

2 O On

3 On O

4 (Min) On On

Detection Speed

— Model 660: Switch position 5 is used to select two detection speeds.

The normal speed utilizes a slower sampling rate and automatic self-

test interval. The high-speed setting increases the data sampling rate

and auto self-test frequency. Toggling switch position 5 “ON” activates

the normal speed option. Toggling switch position 5 “OFF” activates

the high-speed option. The normal speed option is the factory setting

and recommended for most applications.

Industrial or Aircraft Hangar Applications

— Model 860: Switch position 3 is used to select the application

setting. If the detector is to be installed in an industrial environment

(i.e., fuel loading rack, compressor building, tank farm), switch position

3 should be “ON”. If the application is for an aircraft hangar, switch

position 3 should be “OFF”. The false alarm immunity will be slightly

diminished from that of the industrial setting.

Fire Event Analysis Level I or II

— Model 860: Switch position 4 allows the detector to run the

Fire Event Analysis (FEA) program of your choice. FEA Level I is for

installations with normal UV background levels (i.e., no welding). FEA

Level II should be used where detectors are required to detect ames

while welding or other UV generating sources are present. Turning

switch 4 “ON” selects FEA Level I. Turning switch 4 “OFF” will provide

FEA Level II. Level II has slightly diminished false alarm immunity as

compared with Level I.

Relay Adjustments

— Models 660-0XXXX and 860-XXXXX and Model 660-1XXXX

There are two relays and Conguration Option Jumpers, JP1 and JP2,

located on the exposed surface of the printed circuit board (PCB) in the

housing assembly. Using these jumpers, the relays may be congured

as normally open or closed. The factory will ship the detectors with the

following settings.

1.) Fire relay (K2) — normally open:

-will close when there is a re present beyond the re time delay

setting.

-will close when manual test is activated beyond the length of

time for the re delay time setting.

Note: The red, light emitting diode (LED), will be illuminated when

relay closes.

2.) Fault relay (K1) - normally open:

- will close when power is applied (Model 860 after 2 seconds and

Model 660 less then a second).

- will open when power is lost (or fuse F1 on process PCB is open).

- will open when detector fails automatic test.

- will open when detector fails manual test.

- will open when SW7 is on and no loop is present.

Note: The amber LED will be illuminated when relay opens, unless

there is a loss of power.

Note: Any adjustments to the user options listed above should be

done with the power “OFF”. The detectors will not recognize any

changes until the microprocessor is reset. Removing the power allows

a reset to occur.

Caution: Upon applying power, insure that the detector remains on for

at least 5 seconds to allow for complete initialization to take place.

Fire Outputs Latching or Non-Latching

— Models 660 and 860, switch position 6 selects the latching or non-

latching Fire Outputs option. To select latching, the switch position 6

must be toggled “ON”. Upon detecting a re, the Fire Outputs signal

will remain engaged as long as power remains “ON” or until the

detector is reset through the RS485 User Interface (UI). If you select

non-latching by toggling switch position 6 to “OFF”, the Fire Outputs

signal will disengage after a re is extinguished.

Optical Self-Test

— Models 660-XX1XX and 860-XX1XX: These models have a “through-

the-lens” optical clarity-checking feature. The factory setting is for

automatic test only, switch position 1 is “OFF”, and switch position 2

is “ON”. (See Figure 5 and 6 for location of the switches and Figures

7, 8 and 9 that describe the switch settings for the user selectable

interface.) If the addition of the manual test feature is desired, then

toggle the switch position 1 to “ON”. If only the manual test feature is

needed, then toggle the switch position 1 “ON” and switch position 2

“OFF”. If no optical testing is preferred, then ensure that both of these

switches are “OFF”.

Models 660-XX0XX and 860-XX0XX do not have either the manual or

the automatic test feature and do not test the lens for optical clarity.

Switch positions 1 and 2 are non-applicable (N/A) in these detectors.

0 to 20 mA Output

— Models 660-0XXXX and 860-XXXXX switch position 7 selects the 0

to 20 mA output option. If this output is utilized, then switch position

7 must be “ON”. Otherwise, if this output is not used, switch position 7

must be kept “OFF” or it will cause the Fault Outputs to turn “ON”. Table

2 illustrates the order of priority. For the Model 660-0XXXX, priority 2

and 3 is N/A.

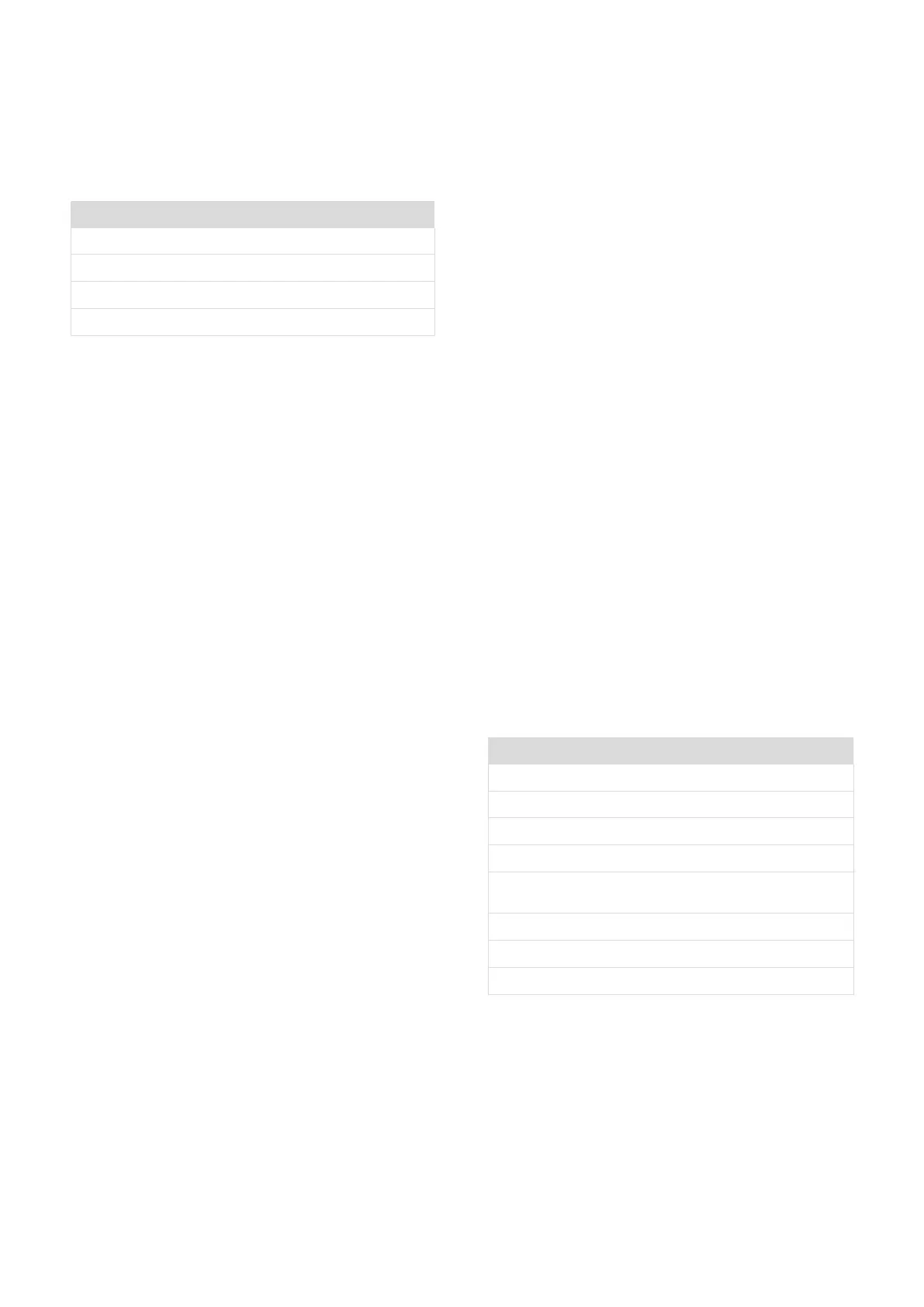

Table 2 – Milliamp Logic Chart

Priority State Load Current mA

1 Fire

20 ± 0.2

2 Warning UV 16 ± 0.2

3 Warning IR 15 ± 0.2

4 Fire Relay Coil Fault 3 ± 0.2

5 Calibration not complete

EEPROM Corrupted Fault

2 ± 0.2

6 Self-Test Fault 1 ± 0.2

7 Current Loop Fault 0 ± 0.2

8 Normal 4 ± 0.2

RS485 User Interface (UI)

The Series 660 and 860 Flame Detectors are equipped with a two

wire, half-duplex, serial communication interface, which is called the

“User Interface” (UI). The RS485 UI will allow up to 31 detectors to

be networked to a controller (i.e., customized re panel or personal

computer). The controller will perform the buss arbiter duties,

because the network is in half-duplex mode. This means that only one

transmitter is allowed on the network at one time.

DMLieferant Тел.: +7 (499) 990-05-50; +7 (800) 775-29-59 dmliefer.ru

Loading...

Loading...