Actuator Maintenance

It is necessary for efficient and

proper operation of the actuator that

all parts be free from dirt, abrasives.

and foreign materials. Upon assembly

at the factory. all synthetic rubber

O-rings have been coated with LUB-

RIPLATE 130.AA, a special lubricant

manufactured and distributed by Fiske

Brothers Refining Company of

Newark. New Jersey, and Toledo.

Ohio. It is recommended that his lubri-

cant ,be used on all O-rings, especially

those on moving parts or in contact

with moving parts. whenever the ac-

tuator is dismantled.

To disassemble a Fisher piston ac-

tuator, proceed as follows:

(References to “positioner” can be

ignored if either a 481 or a 489 ac-

tuator is involved.1

1. Bypass the valve body or shut

off the pressure in the pipeline.

Caution: The adjustable linkage be-

tween the actuator and the main valve

should not be disconnected when the

valve is open with fluid flowing.

(Dampers or louvers should be in safe.

stable positions prior to discon-

nection.)

2. Shut off all pressure to the ac-

tuator. Remove all tubing lines

Icylinder. instrument, and supply)

from the actuator.

3. Remove positioner cover after

loosening the four cover screws on the

underside of the positioner base.

4. Disengage range spring by un~

screwing the spring retainer from the

piston rod extension.

5. Loosen the two cap screwy that

hold the positioner to the cylinder.

When removing the positioner. do not

lose the small O-ring that is used in the

passage from the positioner to the top

of the cylinder.

6. Next remove the clevis bolt

from the adjustable linkage. Remove

the bottom snap ring (Key 26) and un-

screw the cleuis and the boot locknut

from the actuator piston rod.

7. Remove the nuts that hold the

cylinder to the mounting flange and

lift off the cylinder.

8. Remove the stud bolts (Key 13)

that hold the cylinder to the cylinder

flange. Two slots. 180” afx,rt. are lo

Types 480,481, & 489

cated at the lower edge of the

cylinder. Insert a screwdriver in these

slots and pry the cylinder loose. The

pet011 and piston rod will come out

with the cylinder. The piston can then

be removed by pulling it out the open

end of the cylinder,

9. Unscrew both seal bushings,

(Keys 7 and 8).

10. Inspect all parts for eXcessi”e

wear and defects. Replace all worn

O-rings. Lubricate as mentioned above.

11, To reassemble, reverse the

above procedure.

Serial Numbers

Always include the serial number of

your actuator when consulting your

representative for technical advice or

ordering replacement parts. Also in-

clude the complete part number listed

in, the following parts reference sec.

fion. (Some valve types. notably

butterfly valves. do not have the same

valve serial number as the actuator.

Therefore. for proper cross reference,

always include the valve serial number

if it differs from the actuator serial

number.)

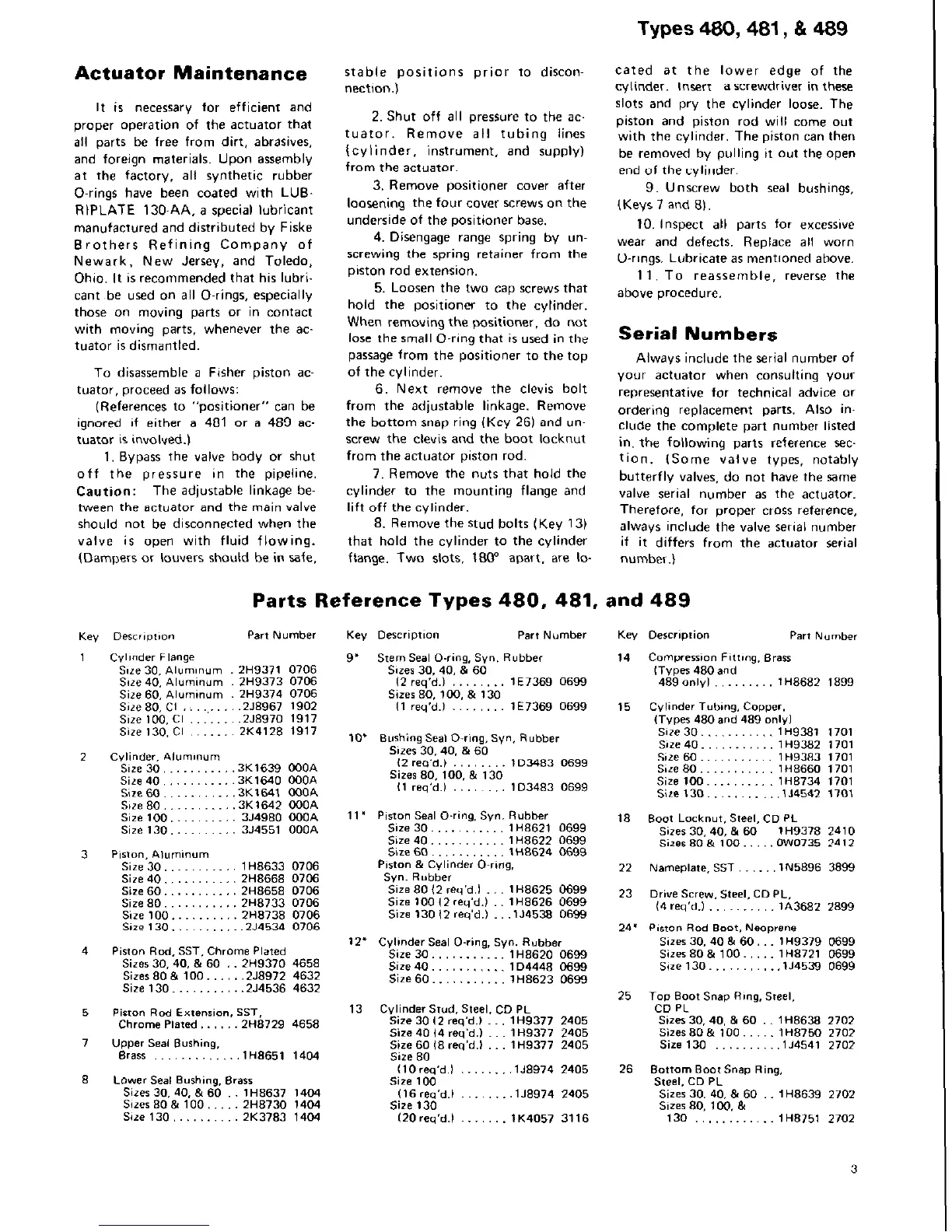

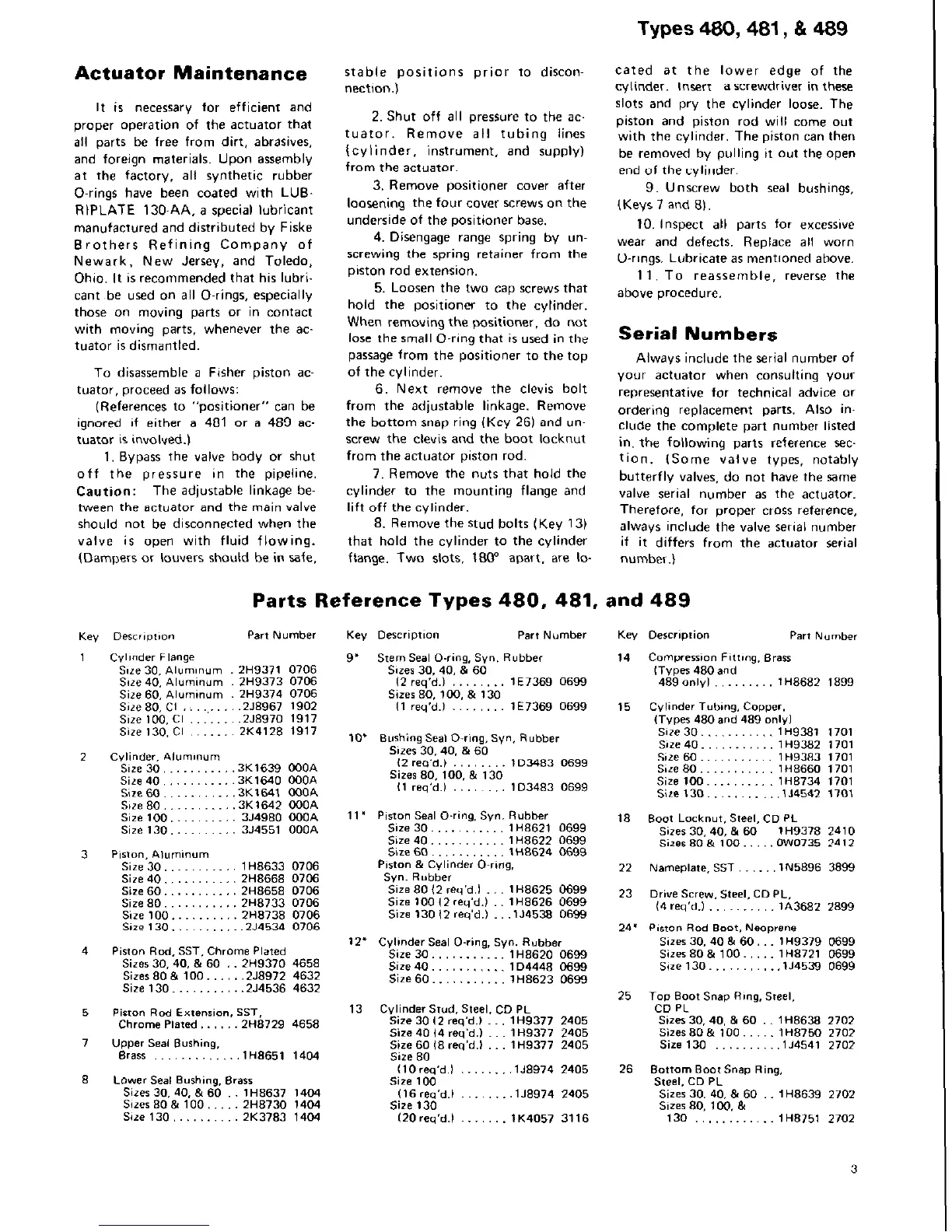

Parts Reference Types 480, 481, and 489

Loading...

Loading...