C1 Controllers and Transmitters

Instruction Manual

September 2009

10

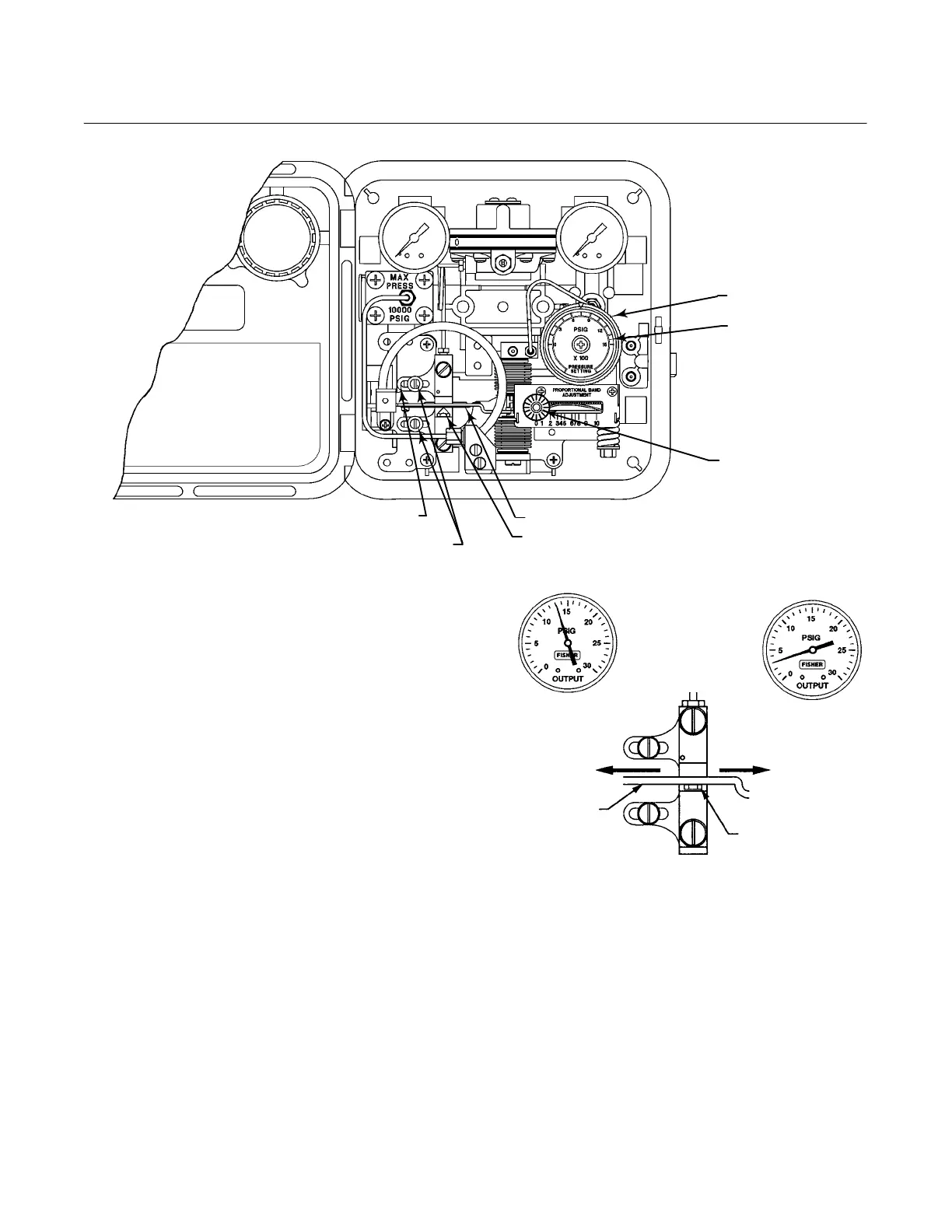

PROPORTIONAL BAND

ADJUSTMENT KNOB

PRESSURE SETTING KNOB

(KEY 58)

PRESSURE SETTING

DIAL (KEY 6)

FLAPPER (KEY 40)

NOZZLE (KEY 54)

CALIBRATION ADJUSTER (KEY 36)

ADJUSTER SCREWS (KEY 48)

GE28280−B

E1059

Figure 4. Proportional−Only Controller Adjustment Locations

Calibration: Proportional−Only

Controllers

Unless otherwise indicated, key number locations

are shown in figure 4.

Provide a process pressure source capable of

simulating the process pressure range of the

controller. If an output pressure gauge is not

provided, install a suitable pressure gauge for

calibration purposes.

Connect a pressure source to the supply pressure

regulator and be sure the regulator is delivering the

correct supply pressure to the controller. The

controller must be connected open loop (Open loop:

The controller output pressure changes must be

dead ended into a pressure gauge). The following

procedures use a 0.2 to 1.0 bar (3 to 15 psig) output

pressure range as an example. For a 0.4 to 2.0 bar

(6 to 30 psig) output range, adjust the values as

appropriate.

1. Complete the above connections and provide a

process pressure equal to the sensing element

range.

2. Rotate the proportional band adjustment knob,

shown in figure 4, to 1.5 (15 percent proportional

band).

3. Verify that the calibration adjuster screws

(key 48) are at mid−position in the calibration

adjuster (key 36) slots.

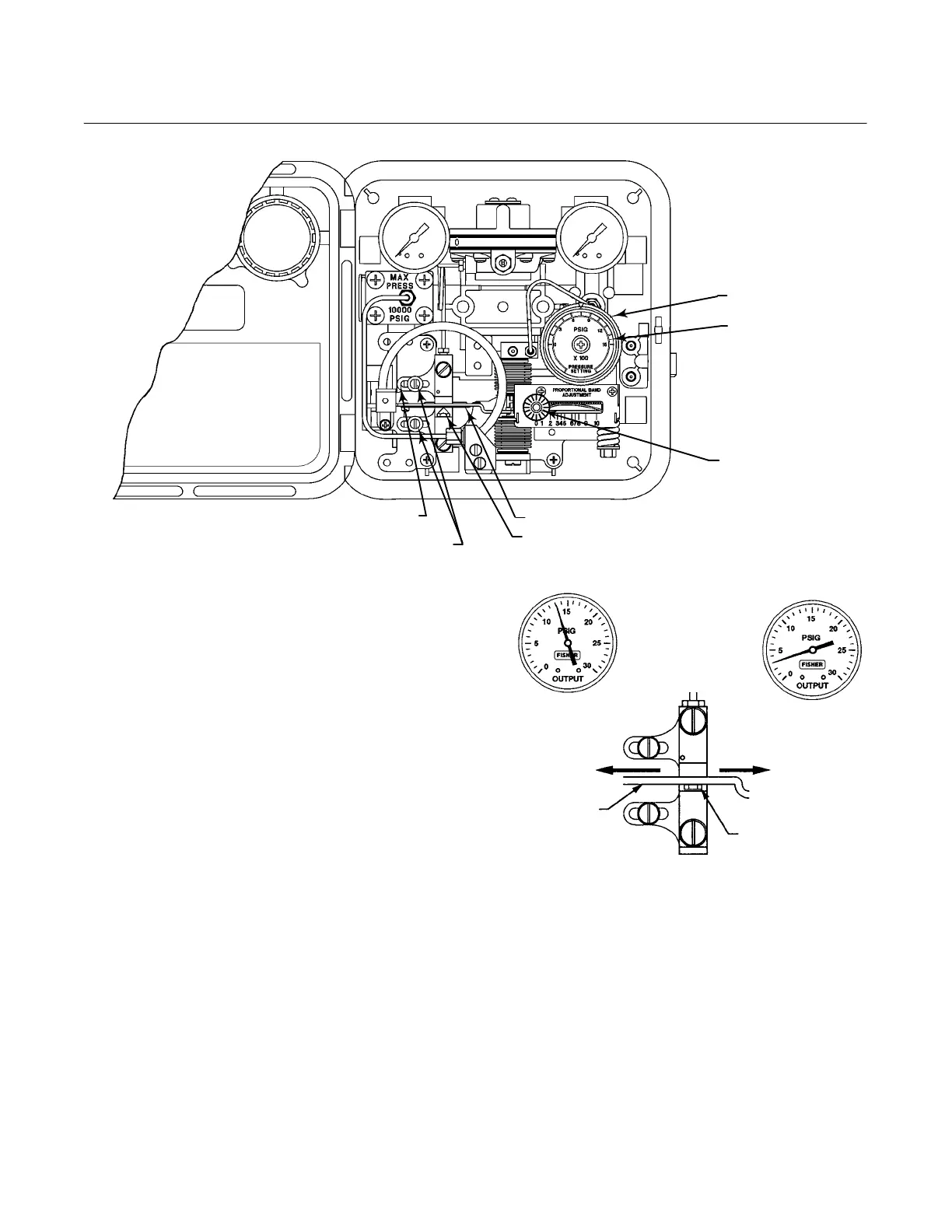

IF OUTPUT IS:

ABOVE

8 TO 10 PSIG

(0.6 TO 0.7 BAR)

BELOW

8 TO 10 PSIG

(0.6 TO 0.7 BAR)

MOVE ADJUSTER

LEFT

MOVE ADJUSTER

RIGHT

FLAPPER

NOZZLE

NOTE:

3 TO 15 PSIG (0.2 TO 1.0 BAR) OUTPUT SHOWN.

FOR 6 TO 30 PSIG (0.4 TO 2.0 BAR) OUTPUT, ADJUST

VALUES AS APPROPRIATE.

A6155−1 / IL

Figure 5. Reverse−Acting Controller Span Adjustment —

Proportional−Only Controllers

Depending upon the controller action, perform one

or the other of the following procedures.

For reverse−acting controllers:

4. Apply an input pressure equal to the sensing

element upper range value.

Loading...

Loading...