2

&LAMCO

M-K Compressor Expansion Automat

Installation and operating instructions

1. Exclusion of liability

All the technical information, data and instructions contained in these operating instructions for

operations that can and are to be performed, are up to date at the time of editing.

They contain our current knowledge and experience to the best of our understanding.

We reserve the right to make technical modifi cations arising fr

om the further development of the

Flamco pr

oduct presented in these operating instructions. For this r

eason, no claims may be

derived fr

om technical data, descriptions and illustrations.

Required operations within the scope of Flamco delivery must be performed by trained

and certifi

ed specialists. This includes such persons having knowledge of applicable safety

conditions. Consequently, Flamco shall not be liable for any losses, subsequential losses,

personal losses arising from the non-observance of safety conditions or as a consequence of the

disr

egard of standard precautionary measur

es when performing such services as transport,

installation, commissioning, r

e-starting, operation, maintenance, testing and repair

, even in the

event that these ar

e not expressly described in these instructions.

Technical illustrations, drawings and graphs may not necessarily repr

esent the actual module,

individual components or spar

e parts supplied.

Drawings are not to scale and contain symbols for the purpose of simplifi cation.

-Reference symbols used in the instructions.

Hazardous voltage

Ignoring this can put your life in

jeopardy, cause fi res or accidents

destruction

For special consideration

Ignoring this may result in

reduced functioning ,overload

or destruction

2. Acceptance of goods

Inspection

The items supplied (equipment, documentation) ar

e listed in the shipping papers.

The contents of the delivery must be immediately checked for completeness and transportation

damage upon arrival.

Incorr

ect or missing items must be immediately identifi

ed. Please note the contents (e.g., for

handling goods, notifi cations of defects...) of the general terms and conditions contained in the

shipping papers.

Compar

e the specifi cations on the type plate of the expansion vessel with the specifi

cations of

your or

der or the details of the relevant pr

oject.

If this expansion vessel is used r

egardless of any differ

ences which have been ascertained (not

used in accor

dance with regulations), it will not be possible to exclude system faults or hazar

ds to

people, animals or objects.

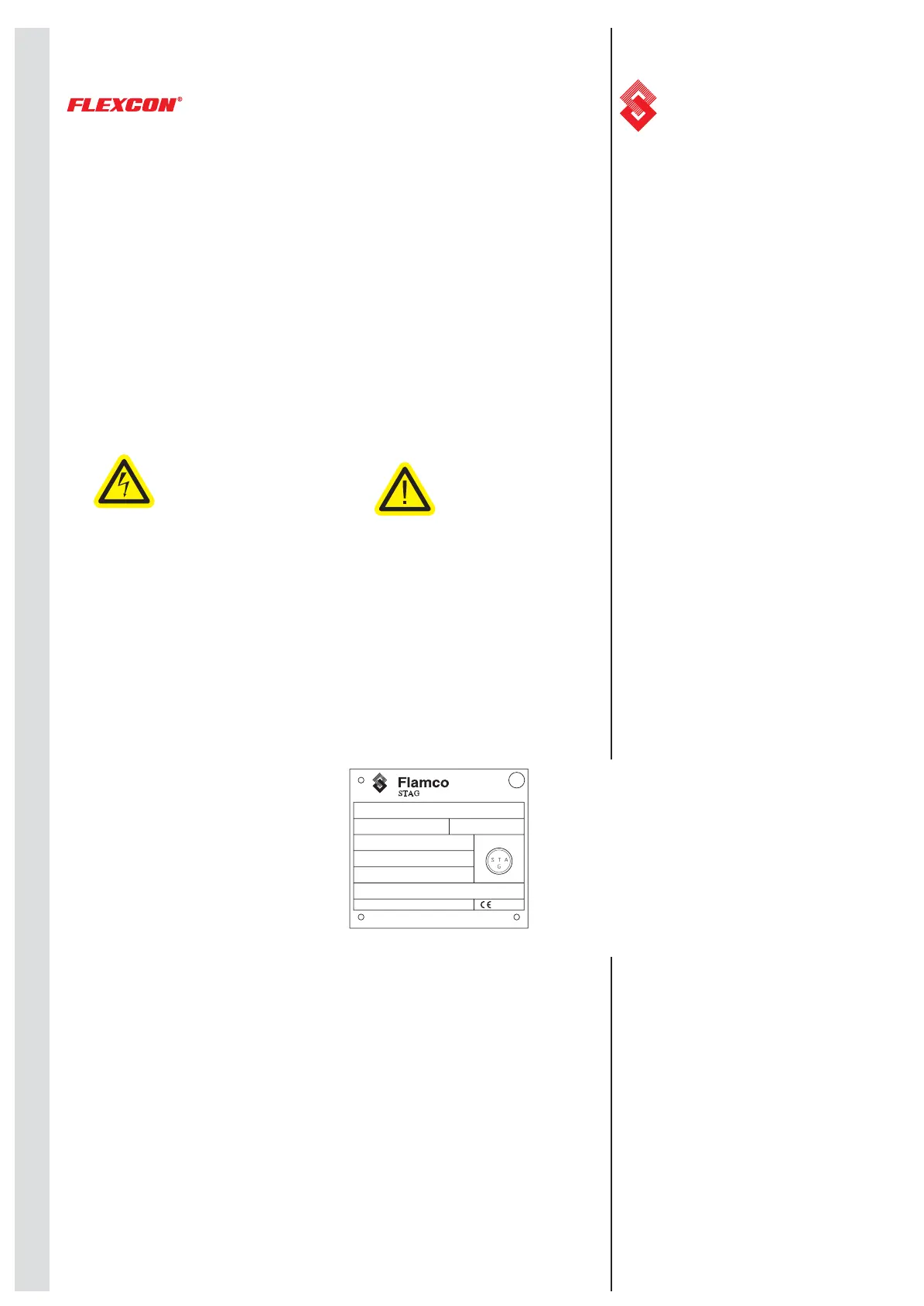

Type plate

- Gas pre-charge mark.

The expansion vessel (basic and ancillary vessel) is under pressure on delivery, which, in

standard situations, is an overpressure of 2.0 bar. This value may be smaller, depending on the

order. The information is at eye-level on the operating side (user position).

(Changes in ambient temperature can cause variations in the pre-charge.)

Transport

The basic and ancillary vessels of the unit are packed horizontally on disposable pallets and

delivered fully assembled. Accessories or add-on equipment (e.g. Compressor Unit K04) can be

packed separately or as a part of the automat unit packaging. The disposable pallets are suitable

for horizontal transport using permitted forklift devices (e.g. forklift trucks, forklift stackers...).

Always use the largest possible fork size for the pallet to prevent the load from tipping over.

Position the object to be moved as low as possible, at right angles to the forks.

Hoist fi ttings on the vessel (welded lifting lugs) are to be used for lifting of the empty, uninstalled

vessel that has been removed from its packaging.

Note: The transport guard (Pos. 46, page 4) provides necessary protection against collision during

the setup of the expansion automat and must only be removed once this is complete!

(Installation surface, setup, page 9)

M

a

n

u

f

a

c

t

u

r

e

r

’

s

m

a

r

k

i

n

g

H

e

r

s

t

e

l

l

e

r

k

e

n

n

z

e

i

c

h

e

n

M

a

r

q

u

e

d

i

s

t

i

n

c

t

i

v

e

d

u

c

o

n

s

t

r

u

c

t

e

u

r

0045

:

:

:

Herstellungsjahr

Year of manufacture

Année de fabrication

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

°C

Flamco STAG GmbH

39307 Genthin

GERMANY

Liter

litre

Zulässige Betriebstemperatur min. / max.

Permissible working temperature min. / max.

Prüfüberdruck

Test overpressure

Zulässiger Betriebsüberdruck

Permissible working overpressure

Nenninhalt

Nominal volume

Serien-Nr.

Serial-No.

Typ

Type

bar

bar

litres

N° de série

Capacité nominale

Surpression d`essai

Surpression de service admissible

Température de service mini. / maxi. admissible

Type

Conformity mark

Manufacturer’s mark

Respective year of manufacture

Permitted operating temperature of the expansion vessel

Permitted test overpressure of the expansion vessel

Permitted operating overpressure of the expansion vessel

Nominal capacity of the expansion vessel

Serial (production) number of the expansion vessel

Type rating of the expansion vessel

Manufacturer’s logo Manufacturer’s address

18502426 broch Flexcon M-K_UK.indd 218502426 broch Flexcon M-K_UK.indd 2 13-07-2006 08:55:2413-07-2006 08:55:24

Loading...

Loading...