10/29/2020 REV. 003 16

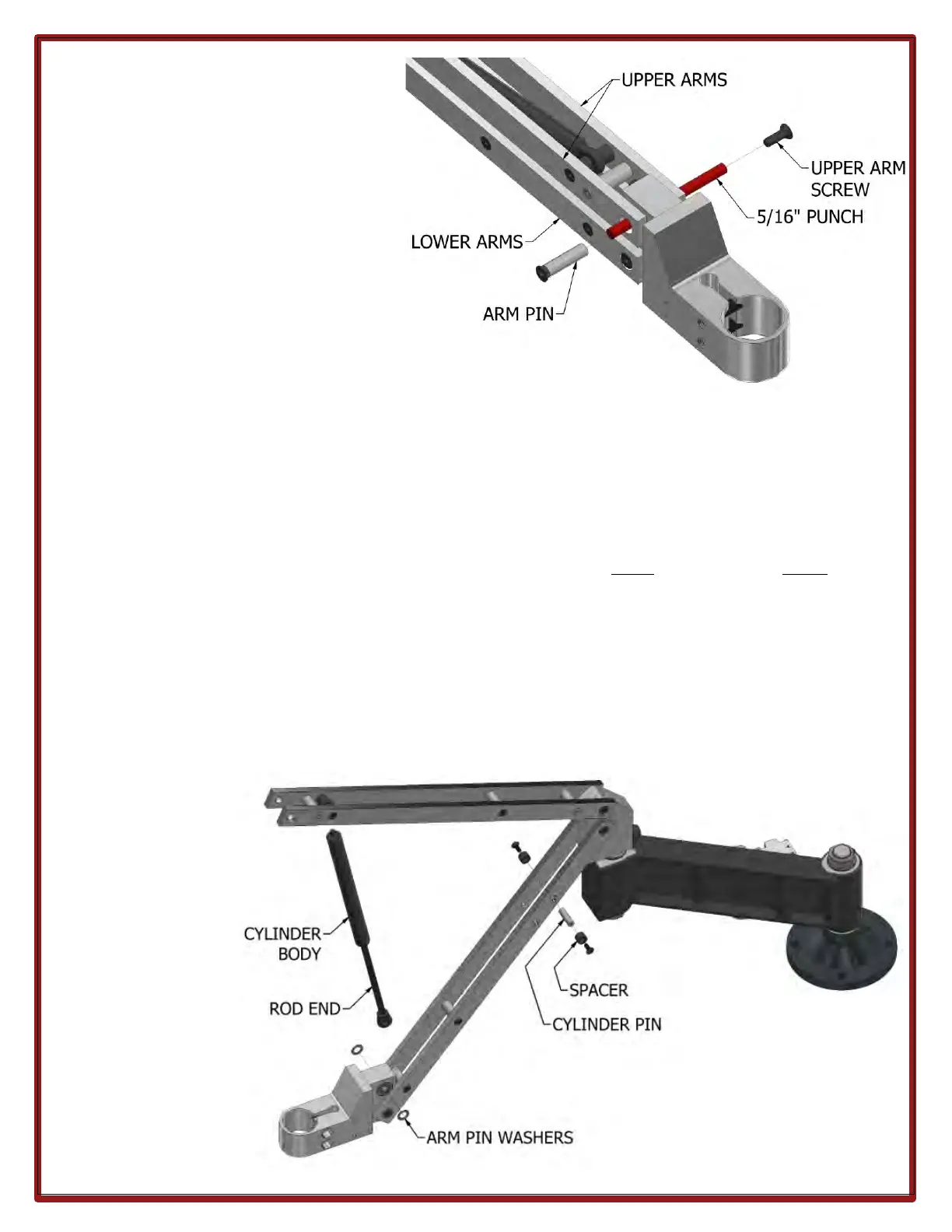

6. Remove the upper arm screw as shown

in Figure 10. Only remove 1 screw (does

not matter which side). Using an Allen

wrench or pin punch, push the arm pin

completely out, leaving the wrench or

punch in place.

CAUTION: Make sure not to damage the

arm pin threads. Also, the cylinder may

still have some pressure. The unit will

shift once the pin is out and the wrench

or punch will be held tightly in the

location where the arm pin used to be.

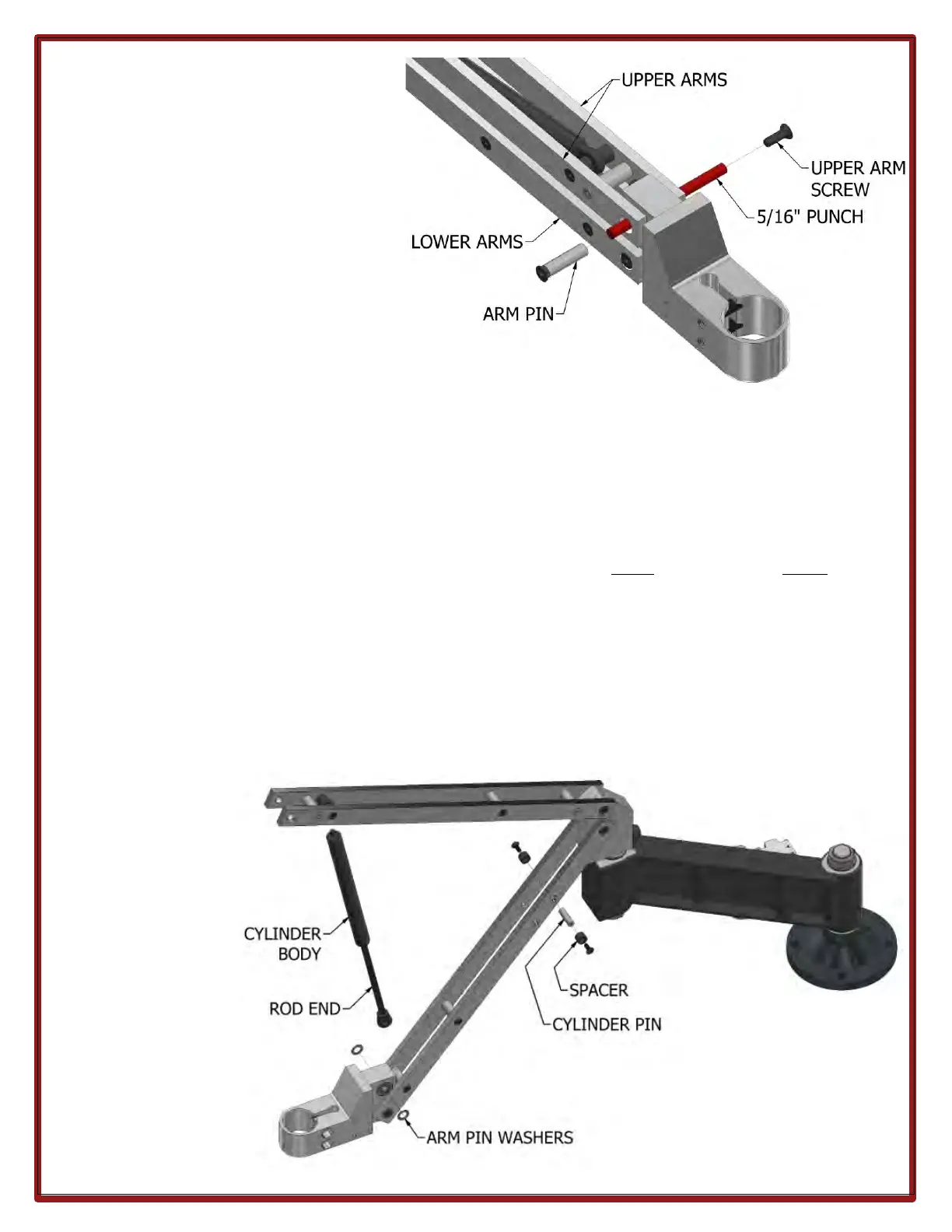

7. Squeeze the upper and lower arms

together with both hands. This will take any pressure off the wrench or punch and allow you to remove it.

CAUTION: Slowly let the arms spread apart. The upper arms will raise to their highest point. The bottom

arms should be guided gently downward to the work surface (see Figure 11).

NOTE: The arm pin washers will fall out during this operation. Make sure not to lose them. Reassembly

without these washers will result in the arm binding during operation. There must be one washer for each

end of the arm pin.

8. Remove the 10-32 flat head screws (2) holding the cylinder pin in the lower arm. Rotate the upper arms

upward so the cylinder can hang freely. Grab the body of the cylinder and rotate it (by hand)

counterclockwise to remove it from the clevis. See Figure 11.

9. On the new cylinder, remove the clevis on the body end and tighten it by hand to the existing clevis on the

arm. The cylinder only needs to be snug; do not overtighten.

10. Install the cylinder pin and nylon spacers onto the new cylinder. With the upper arms in the highest

position, reinstall the new cylinder to the bottom arms by aligning the cylinder pin with the holes in the

bottom arm. Fasten the 10-32 flat head screws to secure the cylinder to the bottom arms. See Figure 11.

NOTE: The new

cylinder should be

installed in the

same orientation

as the original

cylinder. The rod

end of the cylinder

should be

connected to the

bottom arms and

the body end of

the cylinder

should be

connected to the

top arms.

Loading...

Loading...