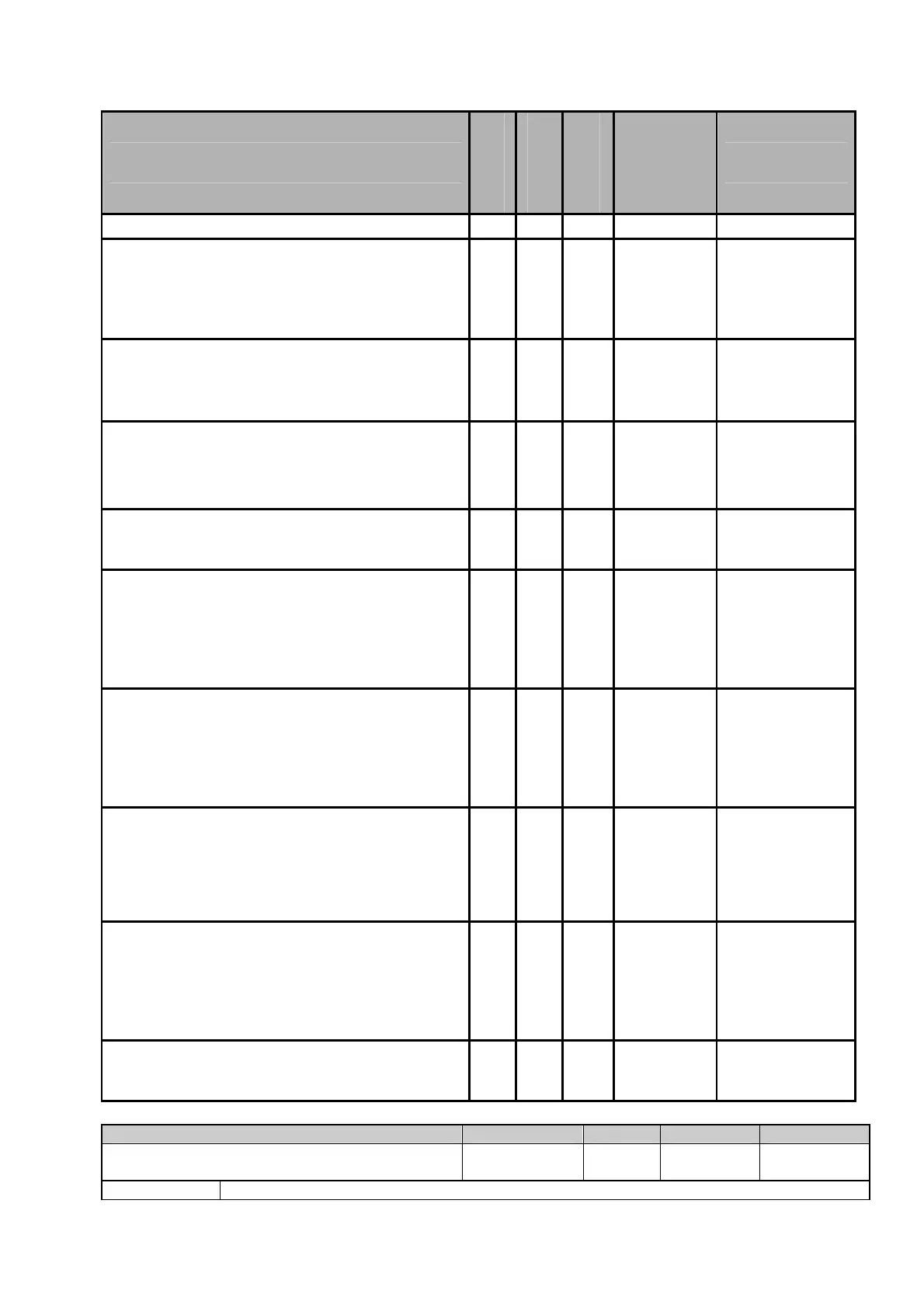

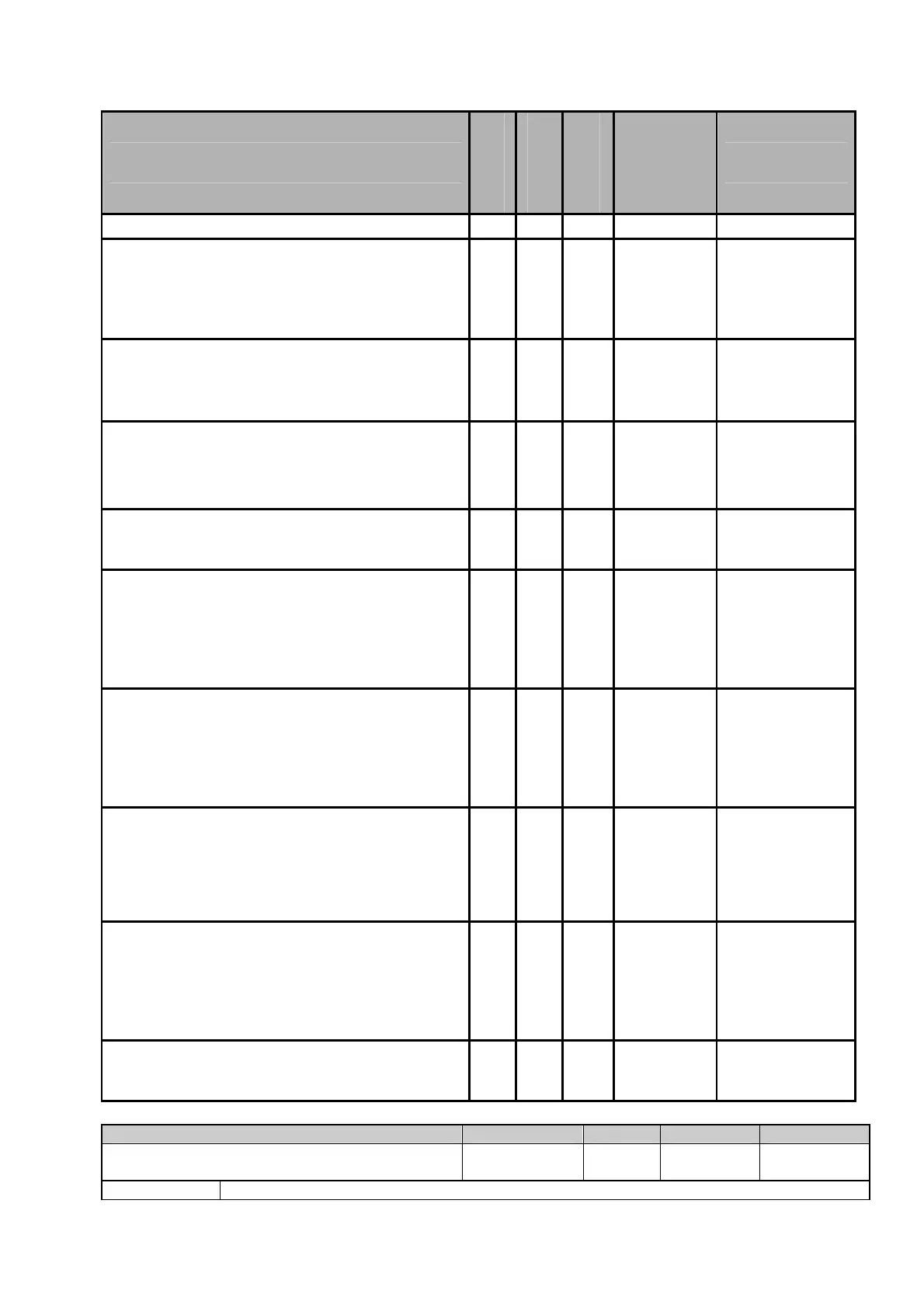

Document Title Document No. Revision

Date Section

Supplement S3 to the AMM CTLS-LSA –

CTLS-LSA with ROTAX 912iS

AF 0480 0011 00 05-Aug-12 05-20-5

Approval Ref.: Approved on the Basis of Manufacturer Self Declaration

Inspection and/or Required Maintenance

Checklist

100hour

Annual

Other Times

Minimum

Level of

Certification

Initials /

Remarks

Refer to Section 28-00.3

Gascolator. Open the gascolator, remove the filter

and check for cleanliness. Clean filter and re-

install. Check gascolator drain valve for correct

function and leakage.

Refer to Section 28-00.3

Pilot/Owner

Fuel shut off valve. Check for security of attachment

and signs of fuel leaks. Check that valve engages

noticeable into the position ON/OFF.

Refer to Section 28-00.3

RLSA-M

Fuel Flow Rate. Check the value of fuel flow rate

as defined in the basic aircraft AMM.

Fuel flow rate: L 40 /____ / (l/h)

R 40 /____/ (l/h).

RLSA-M

Fuel contamination test. Take fuel samples from

both wings. Inspect for contamination, as defined

in the basic aircraft AMM.

Pilot/Owner

Induction system. Check connection of manifolds

between NACA-Inlet, Air filter box and carburetors

for damage, security of attachments and condition.

Inspect connected air hoses for condition and

leakage.

Refer to Section 71-00.3.3

Pilot/Owner

Air filter box. Check that the sealing surfaces are

in good condition and clean. Inspect and clean

filter. Replace if necessary. Clean air filter box

inside. Check the drain hole at the bottom of the

box for obstructions or blockage.

Refer to Section 71-00.3.3

Pilot/Owner

Cabin heater. Check heat shroud and heater

attachments. Check the manifold for holes and

attachments. Check the heater activation system

for proper operation. Check activation system for

wear and security of attachments, as defined in the

basic aircraft AMM

Pilot/Owner

Exhaust system. Checks attachment screws and

springs for security and fit. Inspect system for

damage and missing parts. Visual inspection of

muffler, exhaust pipes and mounting flanges for

cracks, corrosion and leakage.

Refer to CHAPTER 78

RLSA-M

Exhaust muffler. Remove heat shroud from

muffler and inspect muffler for condition, corrosion

and leakage

200h

RLSA-M

Loading...

Loading...