Document Title Document No. Revision

Date Section

Supplement S3 to the AMM CTLS-LSA –

CTLS-LSA with ROTAX 912iS

AF 0480 0011 00 05-Aug-12 71-00-5

Approval Ref.: Approved on the Basis of Manufacturer Self Declaration

71-00.3.2.1 Type of Maintenance

Line

71-00.3.2.2 Minimum Level of Certification

Repairman, Light Sport Aircraft-Maintenance (RLSA-M) or higher

71-00.3.2.3 Procedure

A. Recommended Special Tools and Parts

Item Quantity Unit

Padded support 1 Pcs

B. Engine Mount Inspection

Step Action Reference

1 Remove upper and lower cowlings 71-00.3.1

2

Lift the forward fuselage by pushing down the tail at the narrowest part so that

the Nose Wheel is at least 25 cm (10 inch) off the ground.

3

Insert the padded support securely just behind the firewall (under the fuselage

bottom).

4

Inspect the Engine Mounts 1 and 2 for deformations, cracks, paint delaminating,

corrosion, loose hardware, chafing by cables, wires, hoses, etc., and make sure

that any flexible item is secured to the engine mount.

5 Inspect the rubber Shock Mounts for porosity, cuts, damage and deformations.

6

Inspect the presence of lock wire on engine mounting Screws M10 item 14.

Replace safety wire if necessary.

7

Inspect engine mounting screws for condition and tightening. Check markings of

marked bolts, remove safety wire and re-torque bolts that are safety wired. Re-

install safety wire when done and where applicable.

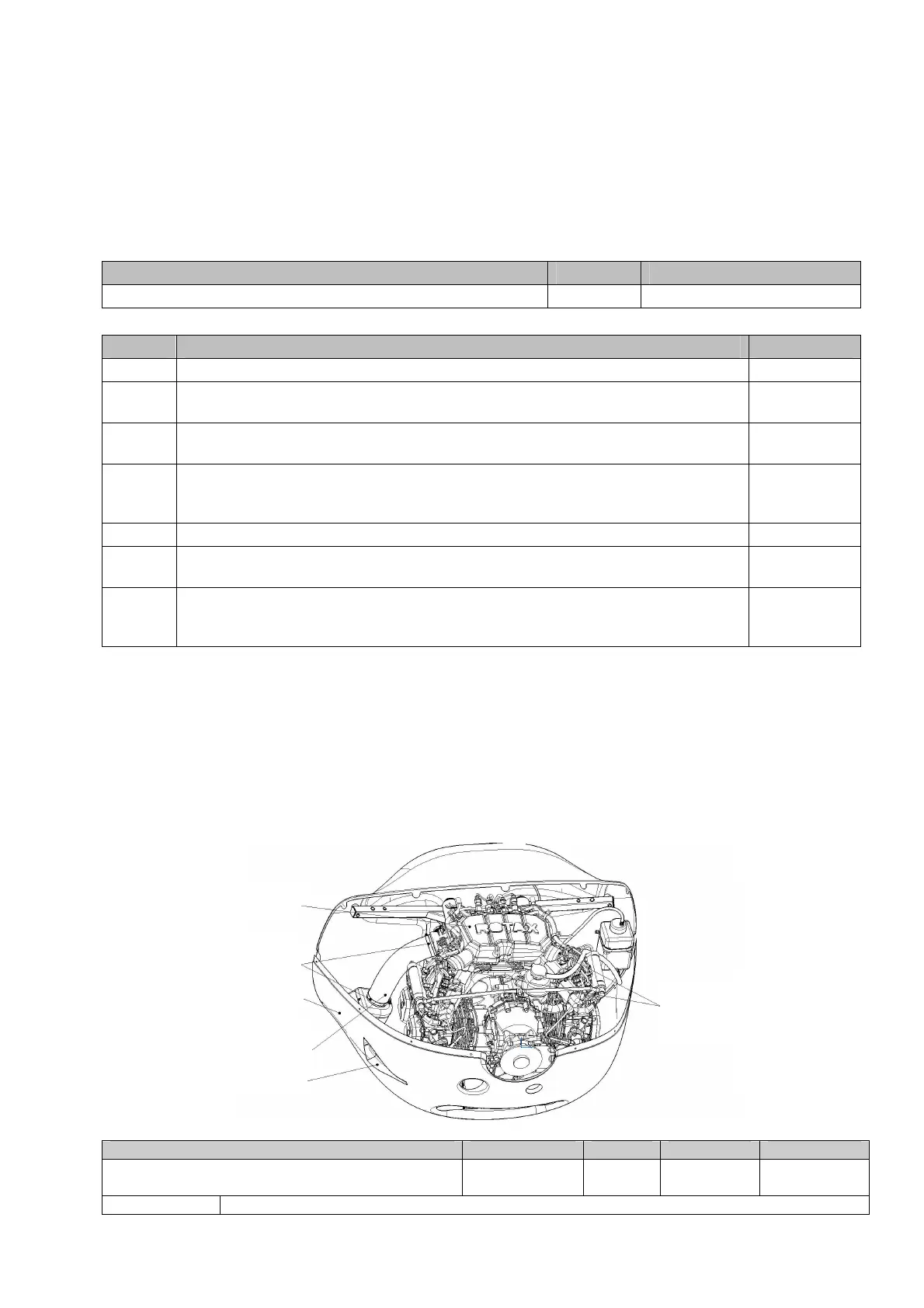

71-00.3.3 Air Intake Inspection

Air is fed into the engine from a NACA inlet at the right side of the lower cowling, through a

cylindrical air filter installed in the filter box at the lower cowling and through throttle body

socket which fills airbox with sufficient airflow.

Airbox is equipped with two pressure sensors and two temperature sensors for both

injection manifolds.

Air intake to fuel injectors flow through intake manifolds. This process is controlled by

ECU, and provide optimized fuel consumption.

Fig. 71-00-3. Air Intake System

Airbox

Intake

Manifold

Clamp

Lower Cowling

Aeroduct Hose

NACA inlet

Loading...

Loading...