SIX-MONTHLY MAINTENANCE

SPLASH GUARD REPLACEMENT

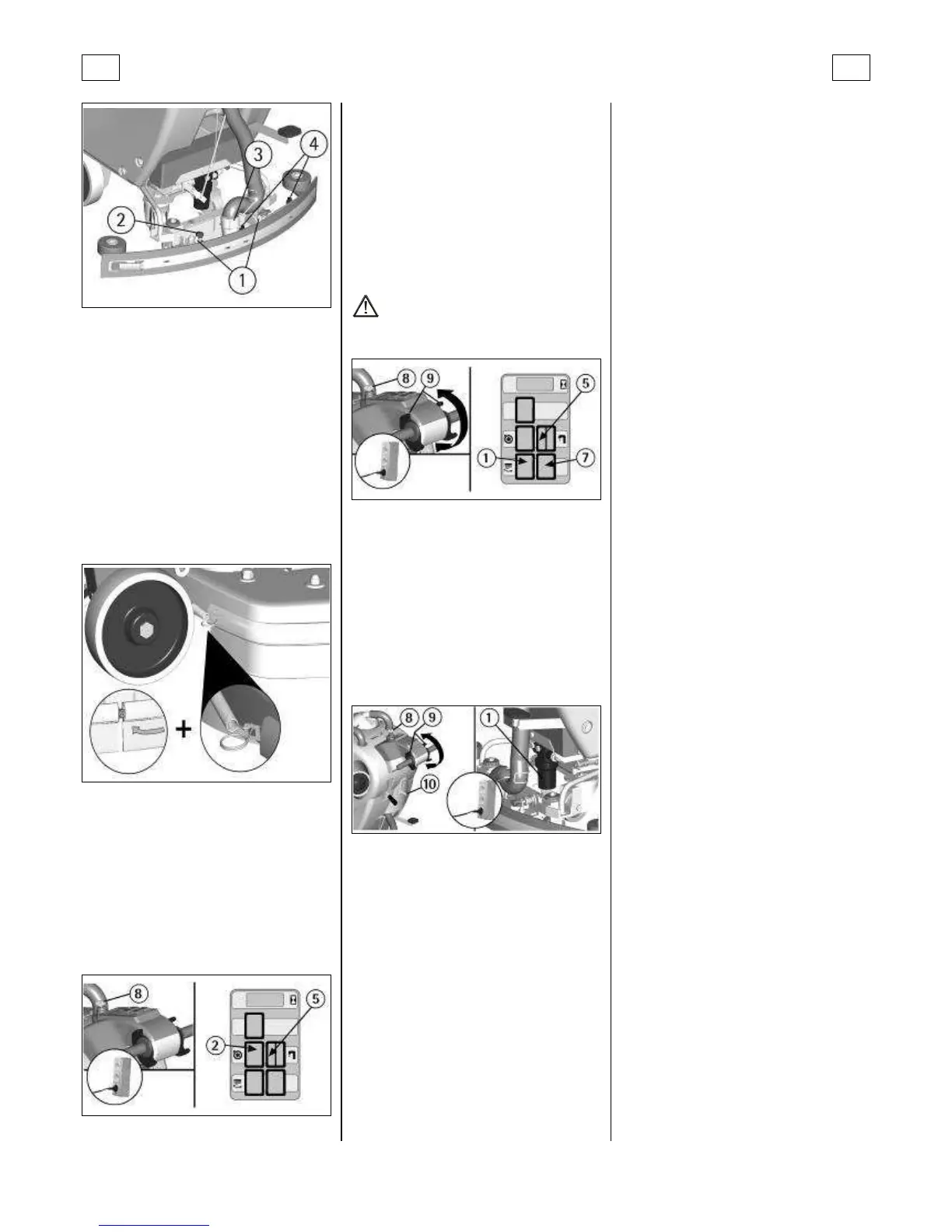

1. Release the spring in the rear part of the

brushes base group from the slot placed at the

extremity of the metal strip.

2. Unscrew the nut on the front part of the

brushes base group and take off the metal strips.

3. Replace the splash guard rubbers and follow

the assembling instructions at “SPLASH GUARD

ASSEMBLY” paragraph.

With brushes assembled, the splash guard must

slightly touch the floor.

The checking of all the other foreseen machine

operations is left to the authorized technical as-

sistance.

TROUBLESHOOTING GUIDE

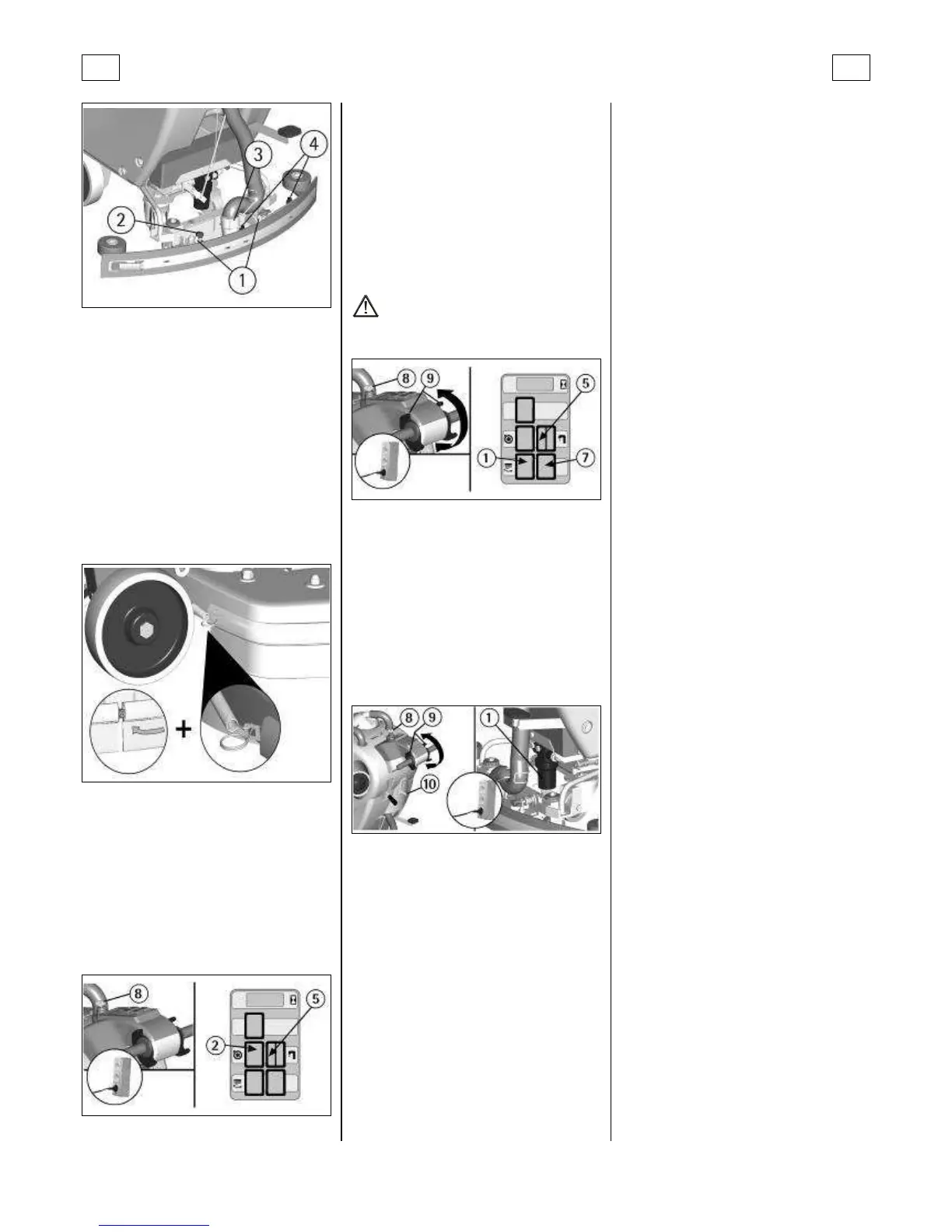

THE SUCTION MOTOR DOES NOT WORK

1. Verify that the signal light for presence of the

tension (5) is on, if necessary, check that the plug

is correctly inserted in a functioning mains socket.

2. The model equipped with the key switch (see

under "OPTIONAL ACCESSORIES”), turn the key (8)

clockwise to switch on the machine.

3. Verify that the switch (2) is on.

If the problem persists, please contact the au-

thorized technical assistance.

THE BRUSHES MOTOR DOES NOT WORK

1. Verify that the signal light for presence of the

tension (5) is on, if necessary, check that the plug

is correctly inserted in a functioning mains socket.

2. The model equipped with the key switch (see

under "OPTIONAL ACCESSORIES”), turn the key (8)

clockwise to switch on the machine.

3. Verify that the switch (1) is on.

4. Activate the levers for presence (9).

5. Check that the brushes motor overload pro-

tection device (7) did not intervene; in this case,

rearm it.

If the problem persists, please contact the au-

thorized technical assistance.

ATTENTION:

Never leave the socket inserted in the mains plug

when the machine is not being used.

INSUFFICIENT WATER ON THE BRUSHES

1. Check that the solution valve lever (10) is

open.

2. Check the level of the liquid in the solution

tank.

3. Check that solution filter (1) is clean.

4. If the machine is equipped with the solenoid

valve (see under "OPTIONAL ACCESSORIES”), act

upon the levers presence (9).

5. The model equipped with the key switch (see

under "OPTIONAL ACCESSORIES”), turn the key (8)

clockwise to switch on the machine.

If the problem persists, please contact the au-

thorized technical assistance.

THE MACHINE DOES NOT CLEAN PROPERLY

1. The brushes do not have the suitable bristle

dimension: use only original brushes. For advice,

contact the authorized technical assistance.

2. The brushes have got worn bristles. Check the

brushes wear condition and eventually replace

them (the brushes have to be replaced when the

bristles have reached a height of about 15mm).

To replace the brushes, see instructions at para-

graph “BRUSHES DISASSEMBLY” and “BRUSHES

ASSEMBLY”.

3. The solution detergent is insufficient: open

more the solution valve.

4. Check that the liquid detergent is in the rec-

ommended percentage.

Contact the authorized technical assistance for

advice.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the squeegee rubbers are clean.

2. Check the height and inclination of the

squeegee (see section “SQUEEGEE” in “BEFORE

USE”).

3. Check that the suction hose is correctly in-

serted in the proper seat on the recovery tank.

4. Clean the suction filter.

5. Replace the rubbers if worn out.

6. Check that the suction motor switch is on.

7. Check that the recovery tank is empty.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been used.

Eventually add small quantities of anti foam liq-

uid into the recovery tank.

Please be aware that a bigger quantity of foam is

produced when the floor is not very dirty. In this

case please dilute detergent solution.

Loading...

Loading...