A

DJUSTMENTS

Pick-Up Belt

—————

The pick-up belt is available in two different configurations: Steel teeth with rubber backup flaps,

(standard) or one row of steel teeth only, (for sandy conditions).

1. Adjusting pick-up head depth: Evenly adjust the depth control threaded rods on each side of the front axle until

the lower edge of the wear strip just contacts the ground. It may be necessary to set deeper for uneven or sandy

ground conditions.

2. Adjusting pick-up teeth depth: Loosen pick-up-belt tension by means of the draw bolt at the top shaft on each

side of the machine. Adjust push bolt on lower shaft equally on both sides of the machine. Check teeth depth

with a straight edge across the bottom of both wears strips.

Steel teeth with rubber back up flaps: For average conditions, the steel teeth should be set 1/8” to 1/4” above

the lower edge of the wear strips.

Steel teeth only: For most conditions where steel teeth are used alone, the teeth should be set flush with the

lower edge of the wear strips.

Note: This adjustment is set at the factory and should not be necessary on a new machine. As the teeth

eventually wear, it will be necessary to replace them. (See diagram for proper replacement length) Always

check teeth depth after installing new pick-up teeth or wear strips.

3. Tension pick-up belt with draw bolts on both sides of machine evenly. Tension may be checked by first

removing one of the pick-up belt covers, then pull up on one set of teeth near the center of the belt, between top

and bottom rollers. The belt is properly tensioned when there is approximately 1-1/4” of deflection. Always

replace covers before resuming operation!

CAUTION: DO NOT OVER-TIGHTEN THE PICK-UP BELT! It is very important to re-check pickup

belt tension frequently, especially on new machines or new belts. Pickup belts have been known to

become tighter with use which will cause the belt to tear and fail pre-maturely! The rubber covered

drive roller does not require as much tension as earlier machines that had bare steel rollers.

4. Always test run machine after making adjustments to insure proper belt alignment.

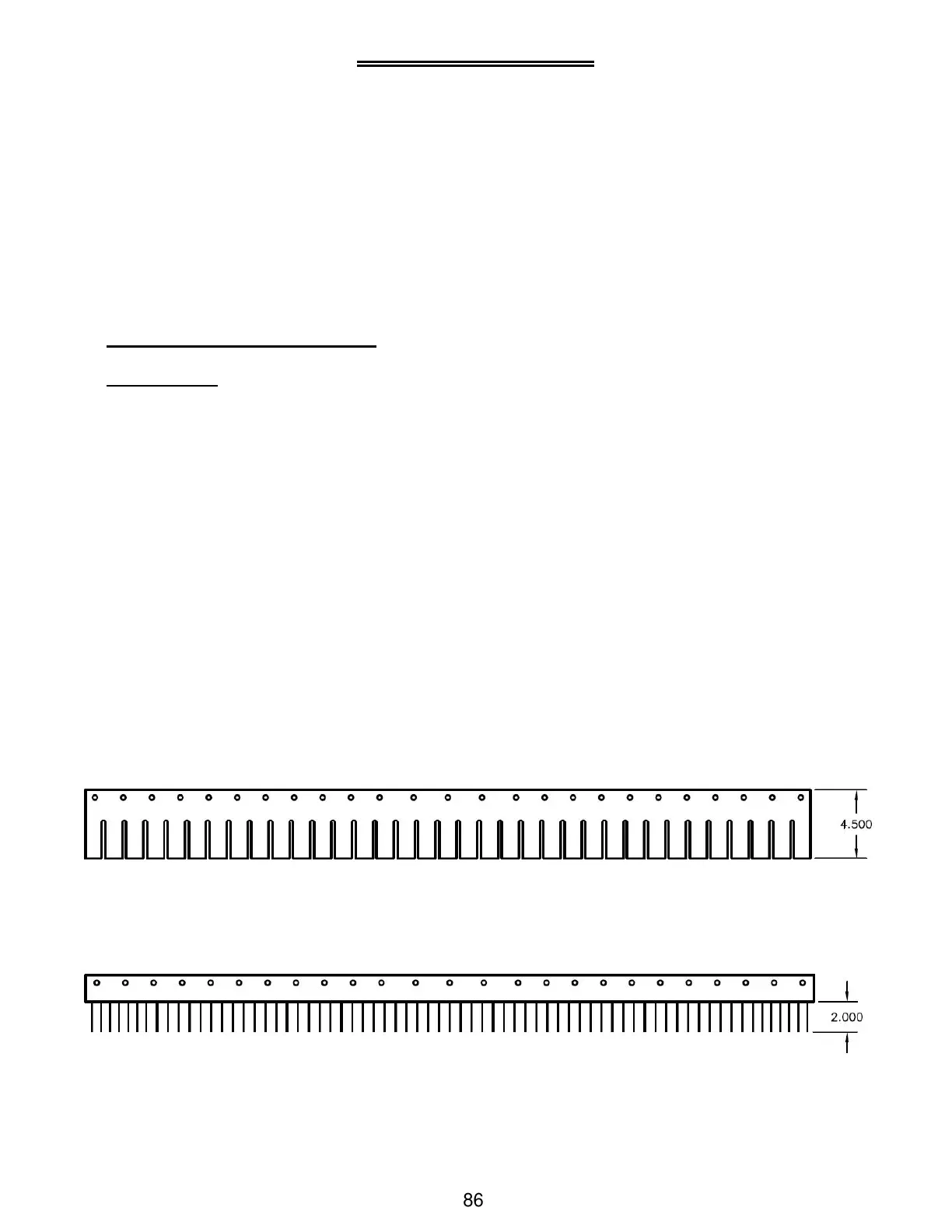

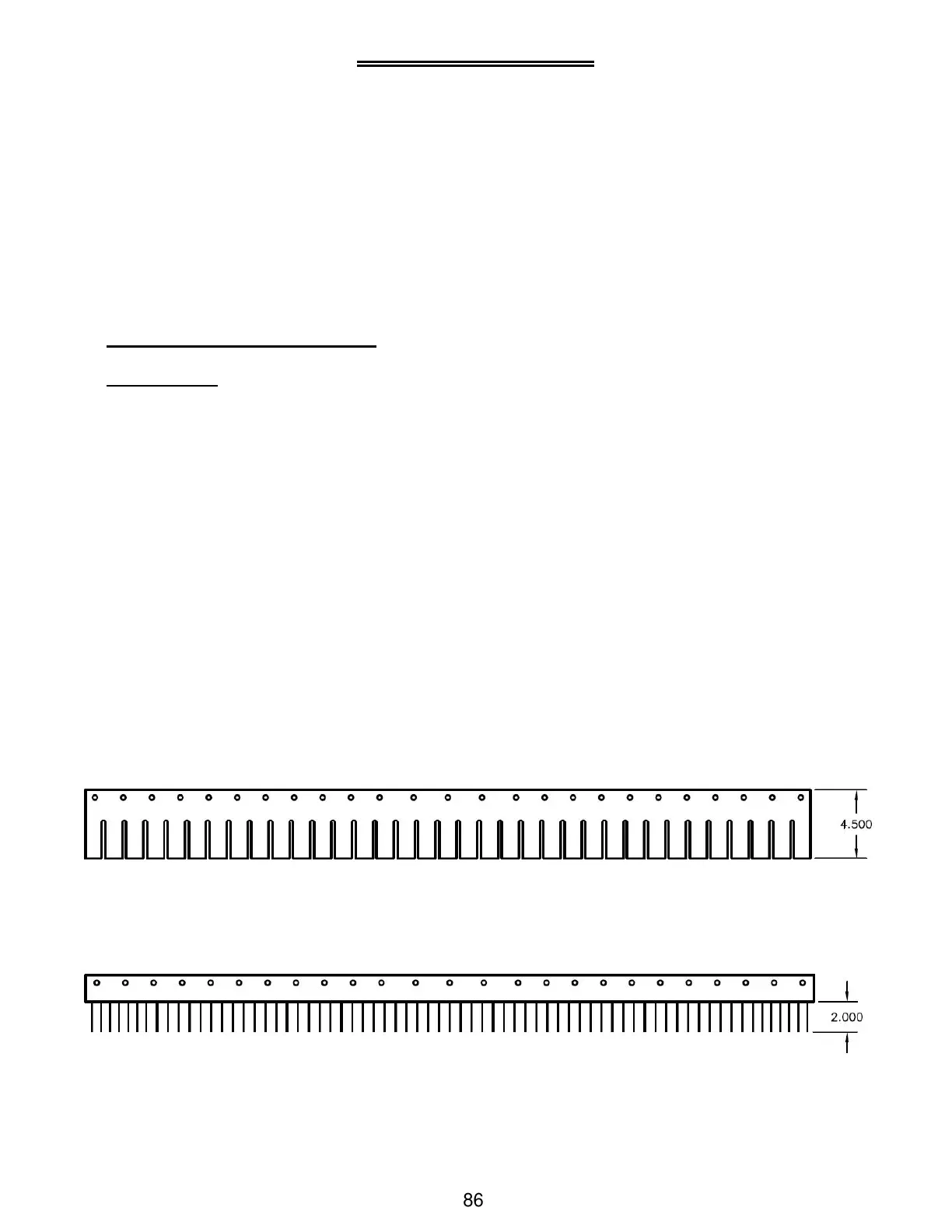

5. The illustration below shows the length of wire pick-up teeth and rubber back up flaps when new. It is

recommended to replace wire pick-up teeth when worn to a length of 1-1/4”. Rubber flaps should be replaced at

the same time as wire teeth.

Rubber Back Up Flap (Part No. F3036)

Pick-Up Teeth (Part No. F3024)

Loading...

Loading...