4

Flow Control Division

Edward Valves

The procedure to be followed in making

the repair is then explained. This includes

normal valve maintenance as well as major

valve repair. Field repair equipment, avail-

able from Edward, is described and

illustrated. Valve lubrication and welding

rod recommendations are also made.

These procedures are adequate for almost

any pressure-seal valve repair or mainte-

nance problem that may arise in the field.

Following is the section describing the

disassembly procedure for the various

valve components; for example, manual of

Limitorque operators, valve yokes, and the

four basic bonnet types. It is very impor-

tant that the Introduction and the para-

graphs titled “First Determine the Area of

Failure” be read and understood before

any disassembly work is begun. Several

procedures are described, depending upon

the area of failure. Considerable time can

often be saved by first selecting the proper

disassembly procedure.

The last major section explains how the

various valve constructions are to be

reassembled. Information on how to

contact Edward for additional advice, if

required, and how to order parts is

included.

Description of

Pressure-Seal Valve Types

Edward pressure-seal valves are built with

four basic bonnet arrangements to provide

the most suitable designs for the wide

range of sizes and pressure classes

offered.

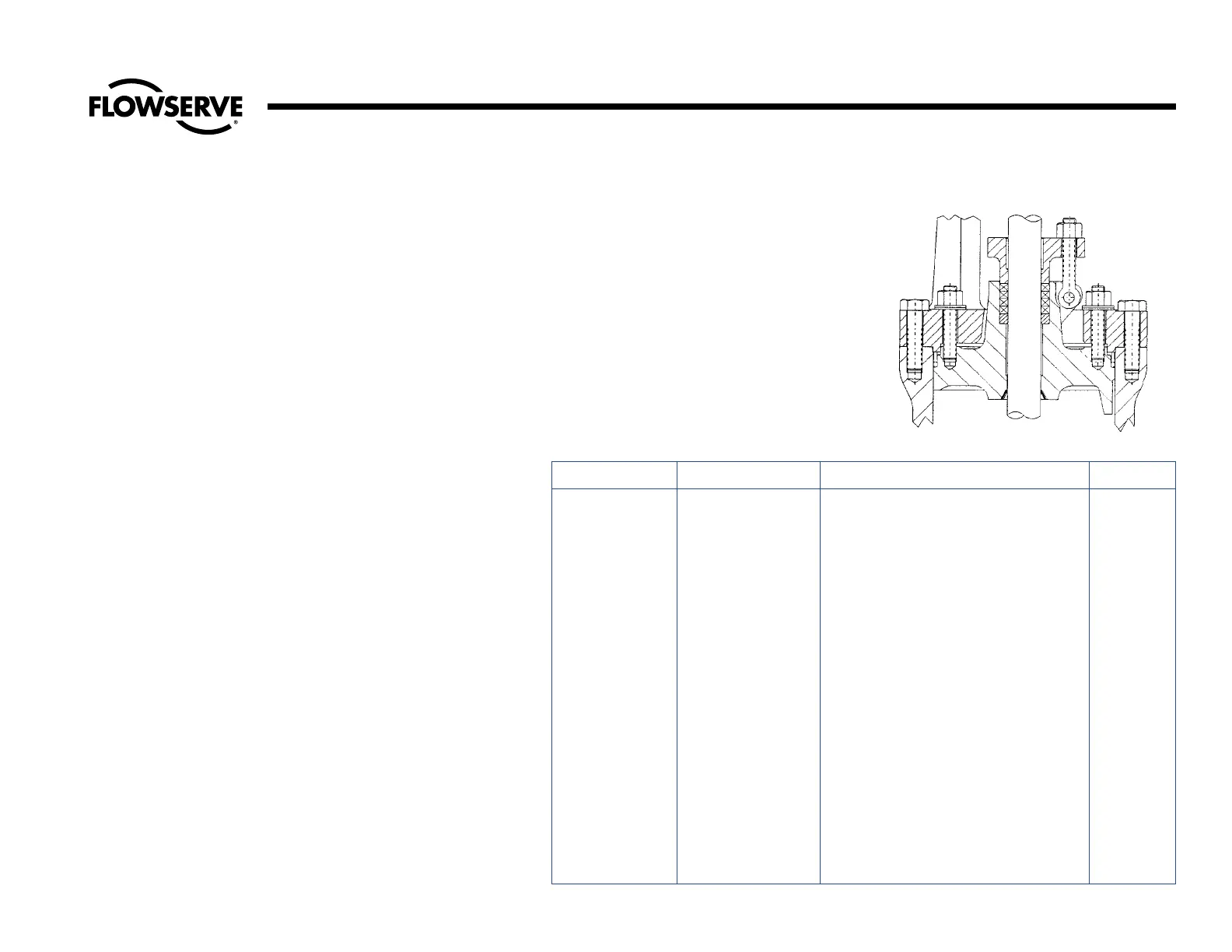

Type I is the studded bonnet design as

shown. It uses the basic pull-up construction

with studs in the bonnet projecting through

the retainer for tightening by use of nuts. It

is a simplified design employed in moder-

ate pressure applications and certain valve

sizes, as shown in the following table.

Description of Pressure-Seal Bonnet Types – Type I

Type I

Illustration No. 1

Pressure-Seal Bonnet

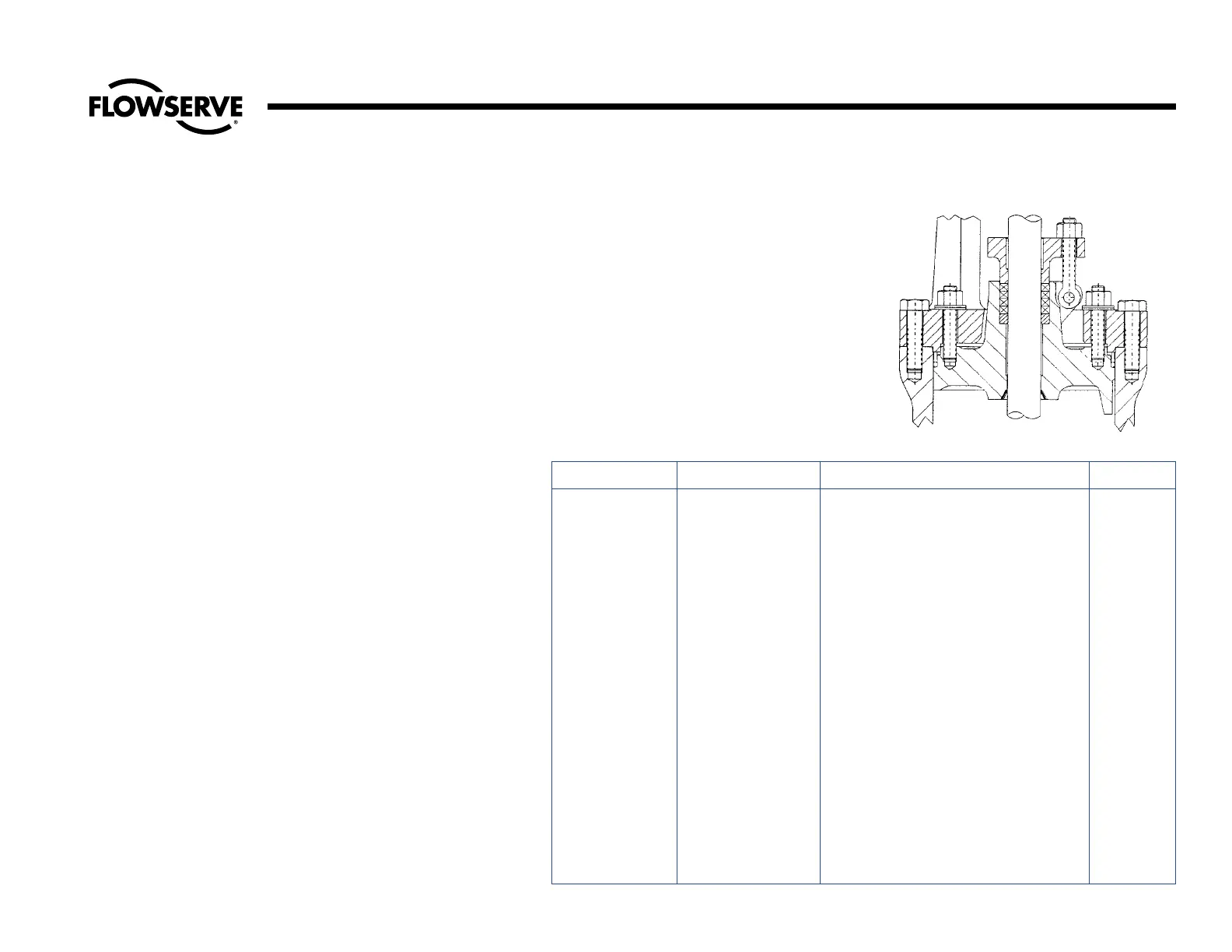

Fig. No. Pressure Rating Type of Valve Size

602Y 600 Flite-Flow Globe Stop-Check (Y-Type) 6-20

606 and 606Y 600 Globe Stop-Check 8-14

607 and 607Y 600 Angle Stop-Check 8-14

614Y 600 Flite-Flow Globe Stop (Y-Type) 6-20

616 and 616Y 600 Globe Stop 8-14

617 and 617Y 600 Angle Stop 8-14

692Y 600 Flite-Flow Check (Y-Type) 16-20

694 and 694Y 600 Horizontal Check 8-14

695 and 695Y 600 Angle Check 8-14

702Y 600-SPL Flite-Flow Globe Stop-Check (Y-Type) 16-20

714Y 600-SPL Flite-Flow Globe Stop (Y-Type) 6-20

792Y 600-SPL Flite-Flow Check (Y-Type) 16-20

1602Y Special Flite-Flow Globe Stop-Check (Y-Type) 16-20

1614Y Special Flite-Flow Check Stop (Y-Type) 16-20

1692Y Special Flite-Flow Check (Y-Type) 16-20

1802Y Special Flite-Flow Globe Stop-Check (Y-Type) 16-20

1814Y Special Flite-Flow Globe Stop (Y-Type) 16-20

1892Y Special Flite-Flow Check (Y-Type) 16-20

Type I

Loading...

Loading...