5

Flow Control Division

Edward Valves

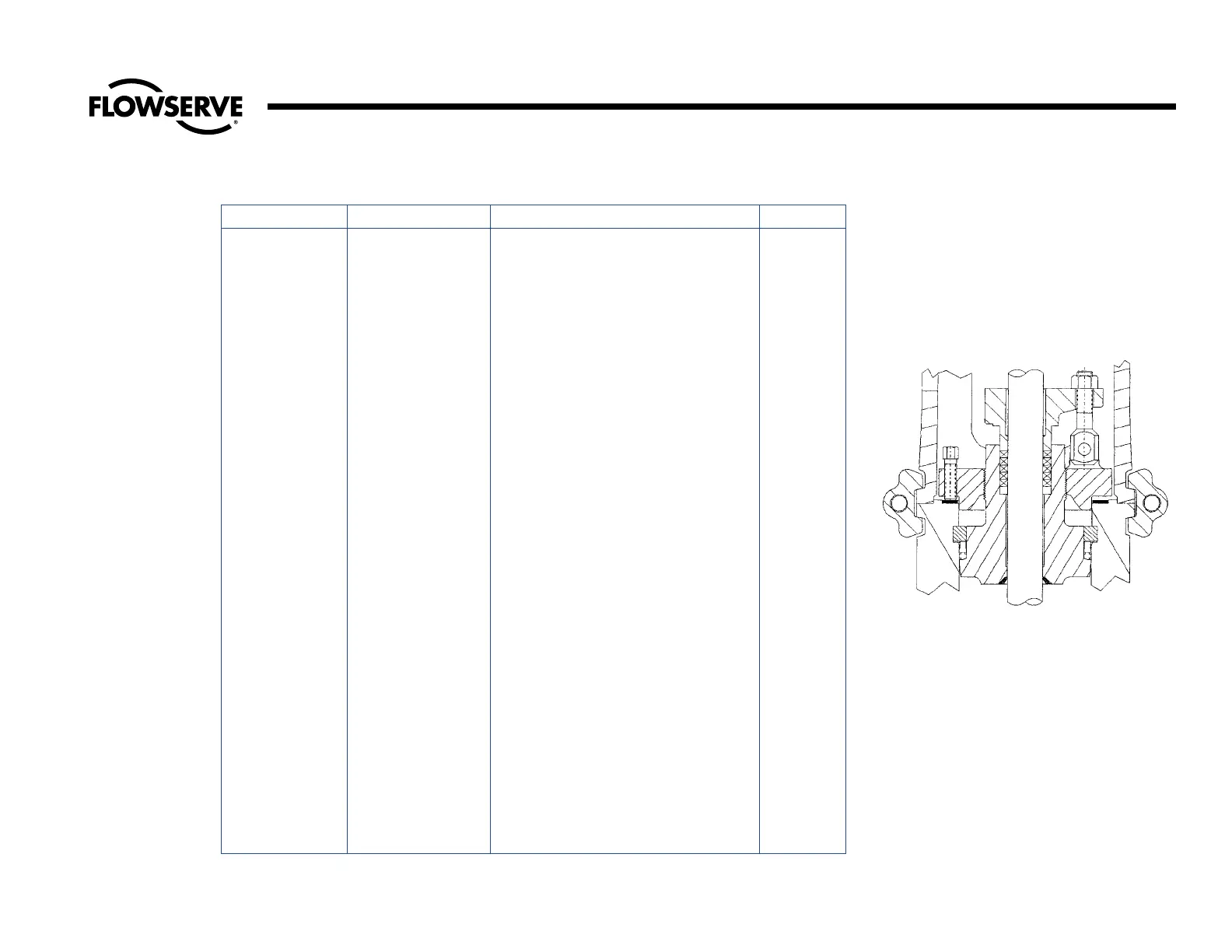

Description of Pressure-Seal Bonnet Types – Type II

Type II

Illustration No. 2

Pressure-Seal Bonnet

Fig. No. Pressure Rating Type of Valve Size

2002Y 1500-SPL Flite-Flow Globe Stop-Check (Y-Type) 3 – 4

2006Y 1500-SPL Globe Stop-Check 2-1/2 – 4

2007Y 1500-SPL Angle Stop-Check 2-1/2 – 4

2014Y 1500-SPL Flite-Flow Globe Stop (Y-Type) 3 – 4

2016Y 1500-SPL Globe Stop 2-1/2 – 4

2017Y 1500-SPL Angle Stop 2-1/2 – 4

3902Y 2500 Flite-Flow Globe Stop-Check (Y-Type) 3-24

3906 and 3906Y 2500 Globe Stop-Check 2-1/2 – 12

3907 and 3907Y 2500 Angle Stop-Check 2-1/2 – 22

3914Y 2500 Flite-Flow Globe Stop (Y-Type) 3-24

3916 and 3916Y 2500 Globe Stop-Check 2-1/2 – 12

3917 and 3917Y 2500 Angle Stop-Check 2-1/2 – 22

3948Y 2500 Elbow Down Stop-Check 10-16

4002Y 900 Flite-Flow Globe Stop (Y-Type) 3 – 4

4006 and 4006Y 900 Globe Stop-Check 2-1/2 – 4

4007 and 4007Y 900 Angle Stop-Check 2-1/2 – 4

4014Y 900 Flite-Flow Globe Stop (Y-Type) 3 – 4

4016 and 4016Y 900 Globe Stop 2-1/2 – 4

4017 and 4017Y 900 Angle Stop 2-1/2 – 4

4302Y 900-SPL Flite-Flow Globe Stop-Check (Y-Type) 3 – 4

4306Y 900-SPL Globe Stop-Check 2-1/2 – 4

4307Y 900-SPL Angle Stop-Check 2-1/2 – 4

4314Y 900-SPL Flite-Flow Globe Stop (Y-Type) 3 – 4

4316Y 900-SPL Globe Stop 2-1/2 – 4

4317Y 900-SPL Angle Stop 2-1/2 – 4

4402Y 2500-SPL Flite-Flow Globe Stop-Check (Y-Type) 3-24

4406Y 2500-SPL Globe Stop-Check 2-1/2 – 12

4407Y 2500-SPL Angle Stop-Check 2-1/2 – 22

4414Y 2500-SPL Flite-Flow Globe Stop (Y-Type) 3-24

4416Y 2500-SPL Globe Stop 2-1/2 – 12

4417Y 2500-SPL Angle Stop 2-1/2 – 22

4448Y 2500-SPL Elbow Down Stop-Check 10-16

4502Y 4500 Flite-Flow Globe Stop-Check (Y-Type) 8-10

4514Y 4500 Flite-Flow Stop (Y-Type) 8-10

4592Y 4500 Flite-Flow Check (Y-Type) 8-10

7502Y 1500 Flite-Flow Globe Stop-Check (Y-Type) 3 – 4

7506 and 7506Y 1500 Globe Stop-Check 2-1/2 – 4

7507 and 7507Y 1500 Angle Stop-Check 2-1/2 – 4

7514Y 1500 Flite-Flow Globe Stop (Y-Type) 3 – 4

7516 and 7516Y 1500 Globe Stop 2-1/2 – 4

7517 and 7517Y 1500 Angle Stop 2-1/2 – 4

Type II

Type II is the push-up design in which the

bonnet retainer ring is screwed onto the

bonnet, and cap screws develop the

upward force. This design is employed on

both intermediate and high-pressure appli-

cations. A three-piece construction is used

for the pressure-seal parts.

Loading...

Loading...