User instructions - MaxFlo 3 - VLENIM0052-02 02.07

15

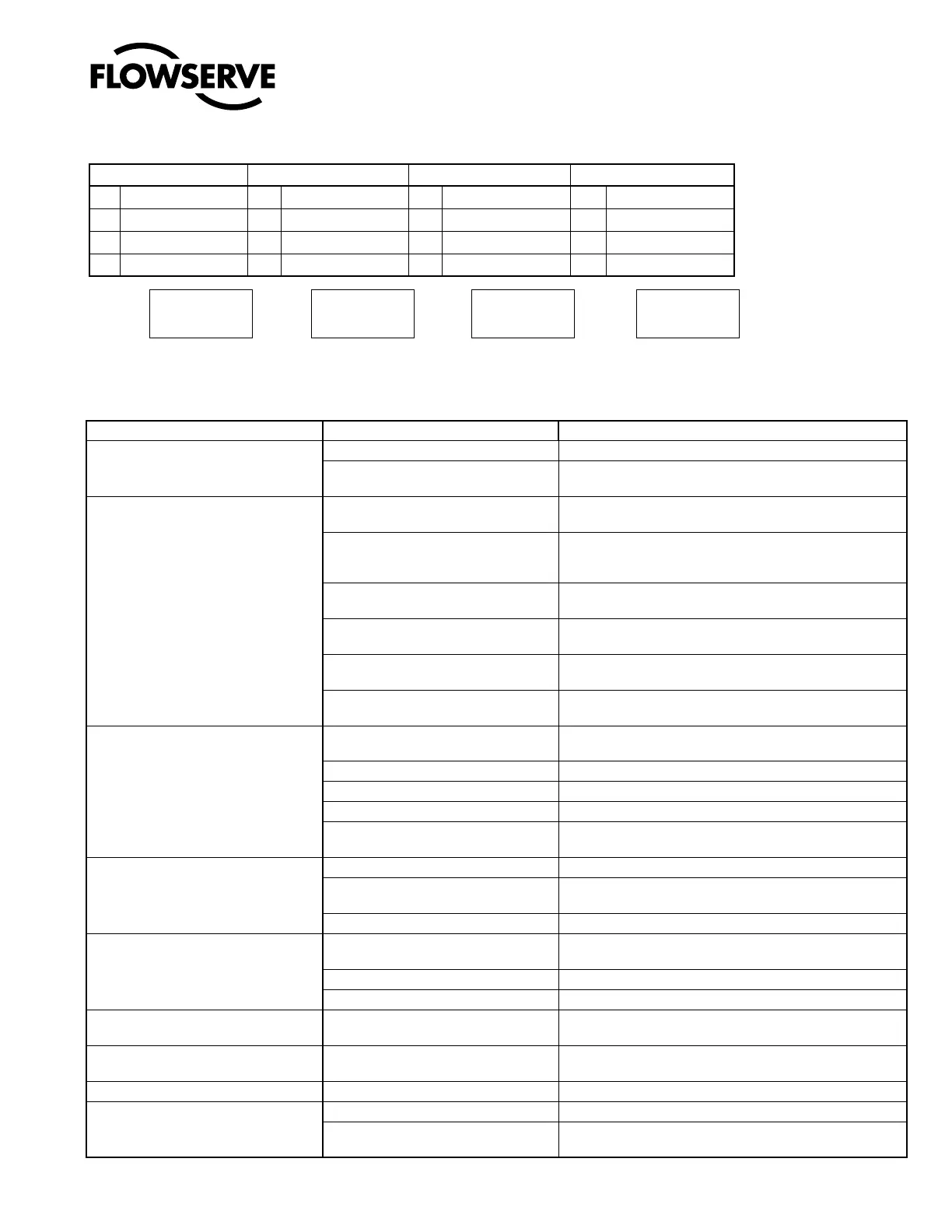

16. TROUBLESHOOTING

Failure Probable Cause Corrective Action

Valve moves to failure position, exces-

sive air bleeding from transfer case

1. Failure of cylinder actuator O-ring 1. Replace actuator O-ring

2. Failure of sliding seal assembly in cyl-

inder actuator

2. Repair or replace sliding seal assembly

Jerky shaft rotation 1. Overtightened packing 1. Retighten packing box nuts to slightly over finger-tight for

V-ring packing, 14 ft-lbs/19 Nm for braided packing.

2. Improper adjustment of lever arm on

shaft causing arm to contact transfer

case

2. Redjust lever arm (see step 1 in Actuator Remounting)

3. Cylinder wall of actuator not lubri-

cated

3. Lubricate cylinder wall with silicone lubricant

4. Worn piston O-ring allowing piston to

gall on cylinder wall

4. Replace O-ring; if galling has occurred replace all damaged

parts

5. Worn actuator stem O-ring causing

actuator stem to gall on stem collar

5. Replace O-ring; if actuator stem is galled replace it

6. Worn (or damaged) thrust bearings,

shaft bearing or packing followers

6. Disassemble and inspect parts; replace any worn or dam-

aged parts

Excessive leakage 1. Improper adjustment of external

stroke stops

1. See Actuator Remounting

2. Improper seat adjustment 2. See Seat Replacement

3. Worn or damaged seat 3. Replace seat

4. Damaged plug seating surface 4. Replace plug

5. Improper handwheel adjustment act-

ing as limit stop

5. Adjust handwheel until plug seats properly

Leakage through line flanges 1. Dirty line gasket surfaces 1. Clean gasket surfaces and reinstall valve

2. Improper sealing of line flanges 2. Tighten line flanges evenly and completely (see Table 1 for

proper torque)

3. Flange or pipe misalignment 3. Reinstall valve in line; check piping system

Leakage through packing box 1. Loose packing box nuts 1. Tighten packing box nuts to slightly over finger-tight for

V-ring packing, 14 ft-lbs/19 Nm for braided packing.

2. Worn or damaged packing 2. Replace packing

3. Dirty or corroded packing 3. Clean body bore and stem, replace packing

Valve slams, wont open, or causes se-

vere water hammer

1. Improper valve installation 1. See step 2 in Installation and correct flow direction

Shaft rotates, plug remains open or

closed

1. Broken shaft 1. Replace shaft, make sure plug does not overstroke and

contact plug stop

Actuator operates, shaft does not rotate 1. Broken internal actuator parts 1. Refer to appropriate actuator maintenance instructions

Leakage through bonnet joint; leakage

from end post

1. Loose bolting or damaged gasket 1. Tighten bolting as recommended in Table II

2. Dirty gasket surfaces 2. Clean gasket surfaces, replace gaskets and retighten bolt

-

ing per Table II

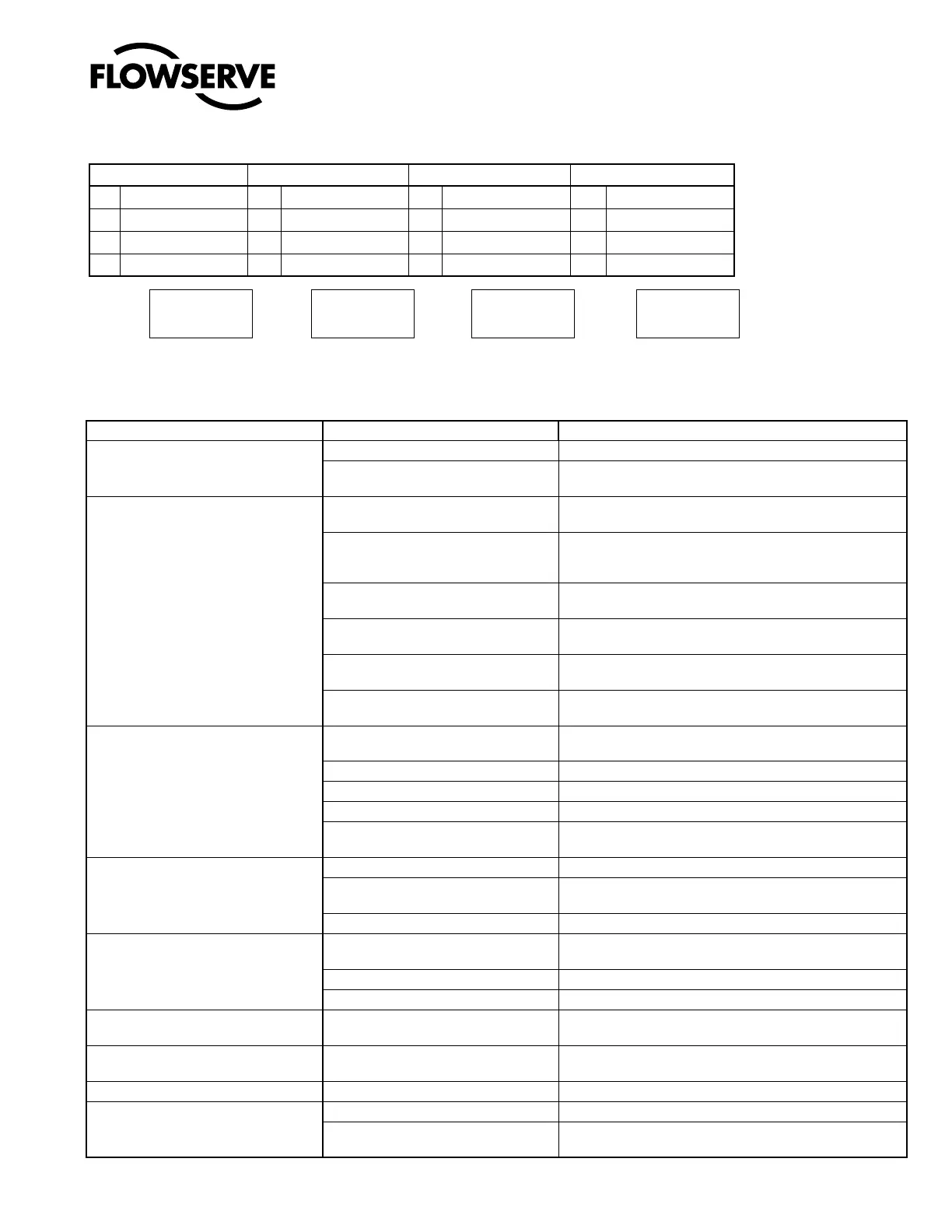

3 - Air Action 4 - Pipe Configuration 5 - Actuator Orientation 6 - Shaft Direction

O

Air-to-open - ATO

L

Left Hand Mounting

L

Left

U

Shaft Upstream

C

Air-to-close - ATC

R

Right Hand Mounting

R

Right

D

Shaft Downstream

D

Flow Down

T

Top (Default)

U

Flow Up

B

Bottom*

AT

3 4 5 6

* Not available on diaphragm actuators

15 PIPE MOUNTING ORIENTATION CODES

Loading...

Loading...