3

2.2. Operating Principle

The flow sensor consists of a transducer and a five-blade open cell paddlewheel using

insertion technology. The paddlewheel is equipped with a permanent magnet

integrated into each blade. As the magnet passes close to the transducer a pulse is

generated. When liquid flows into the pipe, the paddlewheel is set in rotation

producing a square wave output signal. The frequency is proportional to the flow

velocity. The sensor is installed into the pipe using a wide range of insertion type

fittings supplied by the flow sensor manufacturer.

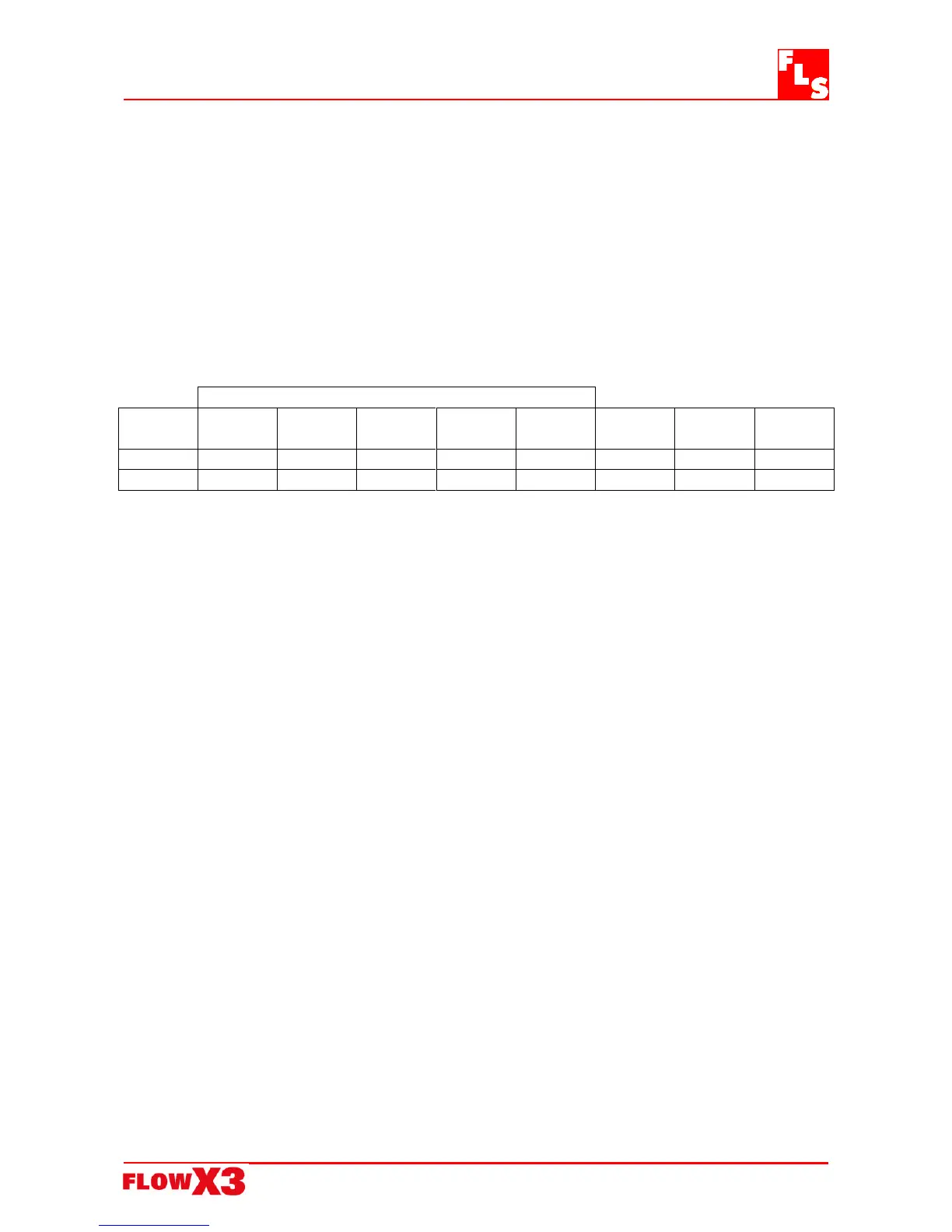

2.3. Connections to FlowX3 Instruments

FlowX3 Instruments

FlowX3

Sensors

F9.00 F9.01 F9.02 F9.30 F9.20 F9.50 F9.51 PLC

F3.20.H X X X X X X

F3.20.P X

* with Output KIT mounted

3. Specifications

3.1. Technical Data

Pipe Size Range: DN40 to DN200 ( 1 ½” to 8” ) . Refer to Installation Fittings section for

more details

Flow Rate Range: 0.15 to 8 m/s (0.5 to 25 ft./s)

Linearity: 0.75 % of full scale

Repeatability: 0.5 % of full scale

Minimum Reynolds Number Required: 4500

Temperature : 120 °C ( 248 °F )

Pressure : 110 bar ( 1600 psi)

Enclosure: IP68

Wetted Materials:

Sensor Body: 316L SS

Flat Gasket : graphite

Rotor: ECTFE (Halar

)

Shaft: 316L SS

Standards & Approvals

Manufactured under ISO 9002

CE

Loading...

Loading...