Issue/Rev. 0.5 (6/11)

MN01029 • Page 5

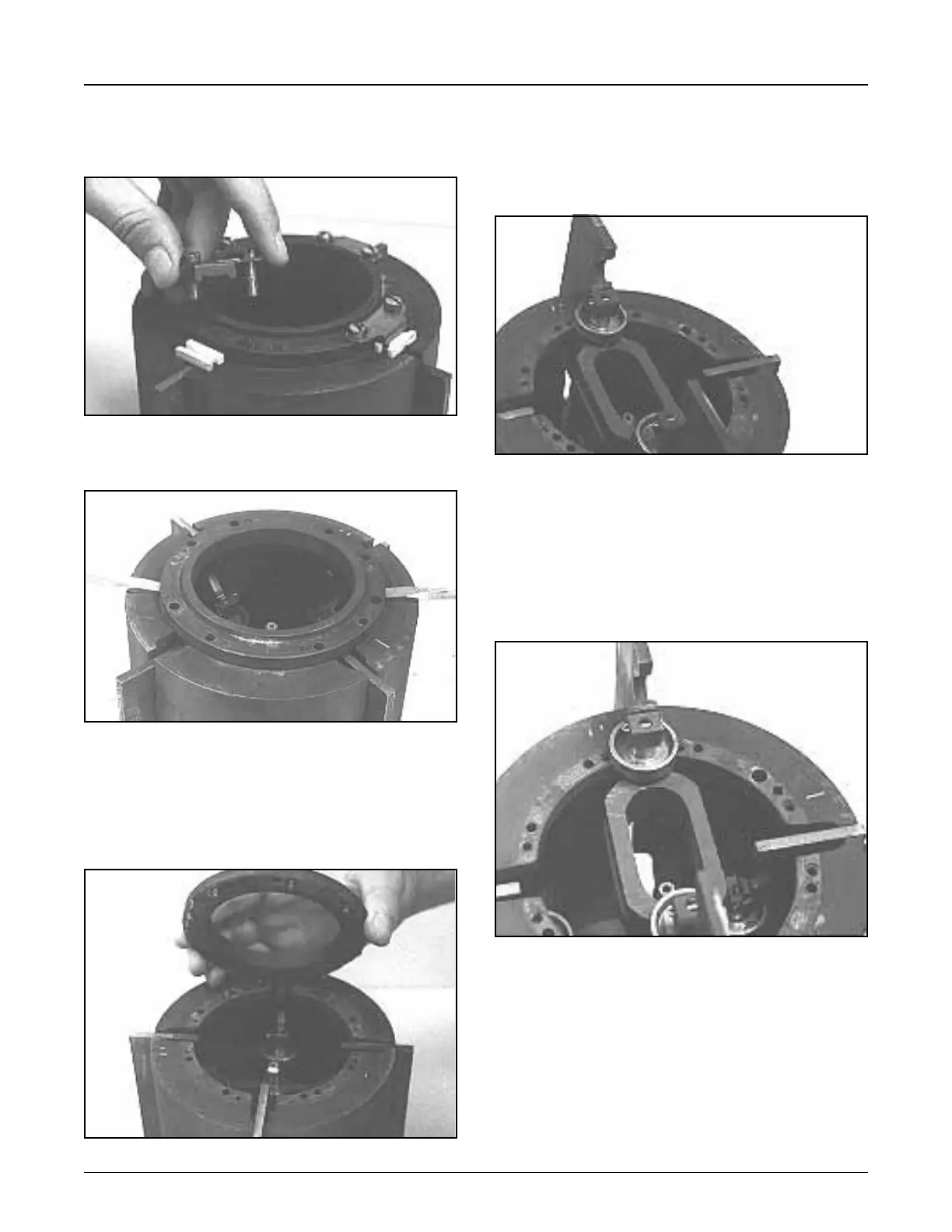

Rotor Disassembly

1. Remove clamps and blade blocks, Figure 11, from

rotor assembly.

2. Using two screwdrivers, pry rotor cover off rotor body,

Figure 12.

•Slotsareprovidedintherotorcovertoacceptthe

screwdriverblades.Withscrewdriversinslots,pry

upward uniformly. Do not pry downward with

screwdrivers, as damage could occur to the

bottom edge of the rotor body.

•Notelocatingpinsinrotorcover,Figure13.

Section 1 – General Information and Description (continued)

Figure 11

Figure 12

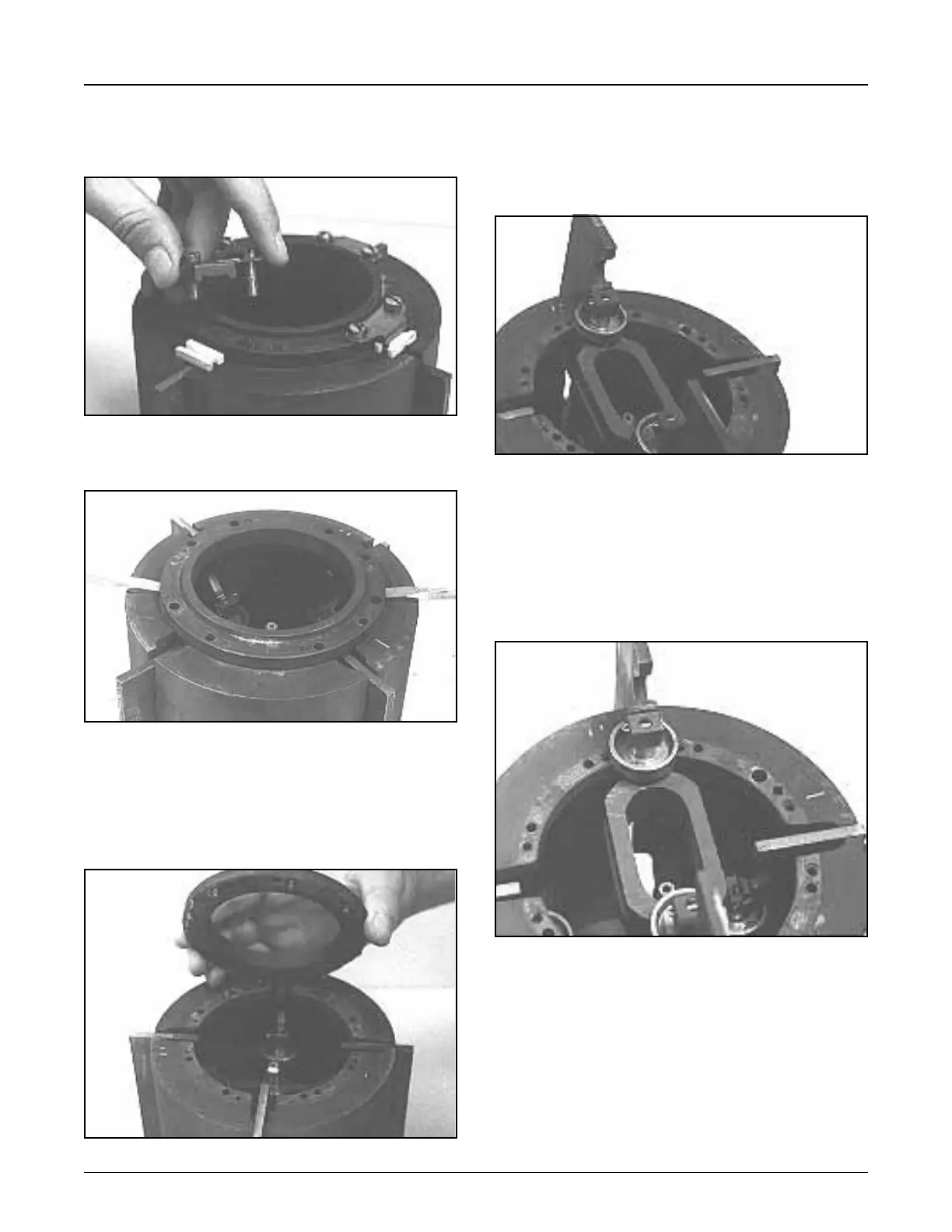

3. The blades are matched to their own slots during

manufacturing. Therefore, before removing blades

from the rotor, the blades and rotor slots must be

matched-marked to eliminate the possibility of install-

ing the blades in the wrong slots or 180° out of position.

• Figure 14 shows one method of marking blades

and rotor. Using a marker, make identical number of

marks on the blade yoke and on an area of the rotor

next to the blade slot. It is unnecessary to mark the

opposite blade paddle for obvious reasons.

•Donotmarkoutsideedgeofrotor.

4. The lower blade assembly can now be removed,

Figure 15.

•Because of the position of the rollers, it will be

necessary to maneuver the blade assembly out of

the rotor.

•Handle blade carefully so that the edges of the

blades are not damaged.

5. Place identification marks on the upper blade yoke

and rotor, Figure 15, and remove from rotor.

•Usedifferentsetofmarksthanusedonlowerblade.

Figure 13

Figure 14

Figure 15

Loading...

Loading...