CONTROLS, INSTRUMENTS AND

OPER'ATION--

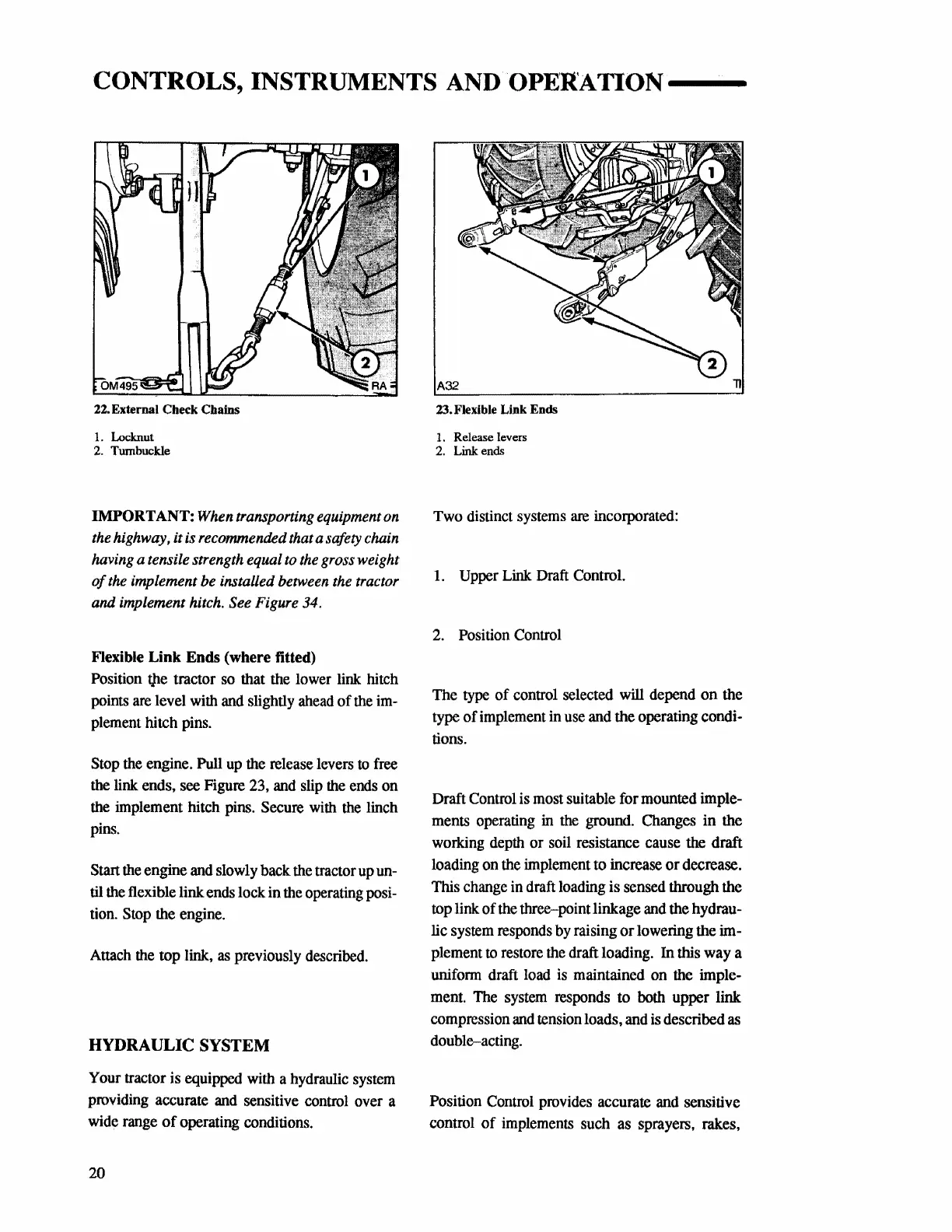

22. External Check Chains

1.

Locknut

2. Turnbuckle

IMPORTANT:

When

transporting equipment

on

the

highway, it

is

recommended that a safety

chain

having a tensile strength equal

to

the

gross

weight

of

the

implement be installed between

the

tractor

and implement hitch.

See Figure

34.

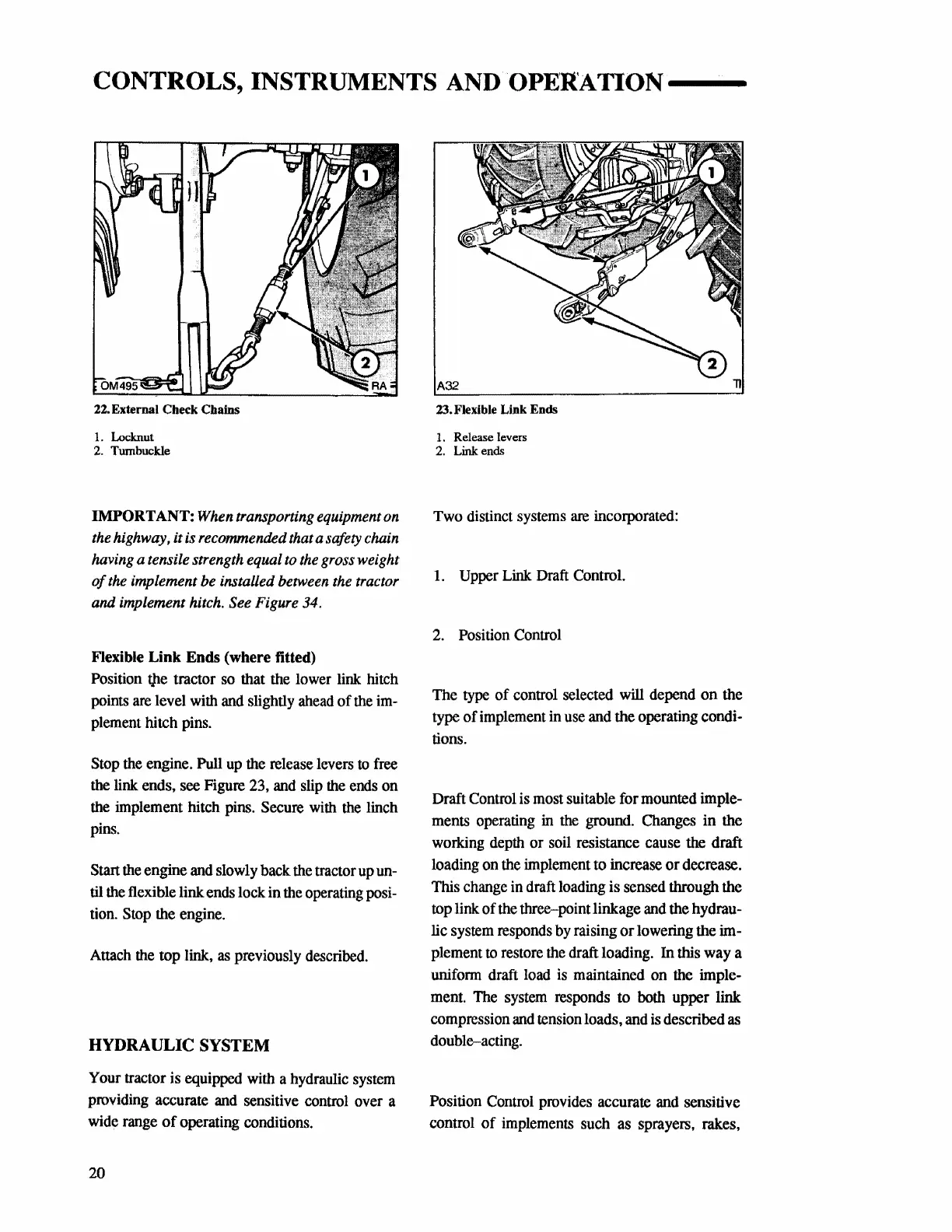

Flexible Link Ends (where titted)

Position

tJte

tractor

so

that

the

lower

link

hitch

points

are

level

with

and

slightly

ahead

of

the

im-

plement

hitch

pins.

Stop

the

engine. Pull

up

the

release

levers

to

free

the

link

ends,

see

Figure

23,

and

slip

the

ends

on

the

implement

hitch

pins.

Secure

with

the

linch

pins.

Start

the

engine

and

slowly

back

the

tractor

up

un-

til

the

flexible

link

ends

lock

in

the

operating

posi-

tion.

Stop

the

engine.

Attach

the

top

link,

as

previously

described.

HYDRAULIC SYSTEM

Your

tractor

is

equipped

with

a

hydraulic

system

providing

accurate

and

sensitive

control

over

a

wide

range

of operating

conditions.

20

A32

23. Flexible Link Ends

1. Release levers

2.

Link ends

Two

distinct

systems

are

incorporated:

I.

Upper

Link

Draft

Control.

2.

Position

Control

The

type of

control

selected

will

depend

on the

type of

implement

in

use

and

the operating condi-

tions.

Draft

Control

is

most

suitable for

mounted

imple-

ments

operating

in

the

ground.

Changes

in the

working

depth

or

soil

resistance

cause

the

draft

loading

on

the

implement

to

increase or decrease.

This

change

in

draft

loading

is

sensed

through the

top

link of

the

three-point linkage

and

the hydrau-

lic

system

responds

by

raising or lowering the

im-

plement

to

restore

the

draft

loading.

In

this

way

a

unifonn

draft

load

is

maintained

on

the

imple-

ment.

The

system

responds

to

both

upper link

compression

and

tension

loads,

and

is

described

as

double-acting.

Position

Control

provides

accurate

and

sensitive

control of

implements

such

as

sprayers, rakes,

Loading...

Loading...