45

Use and maintenance ATOMIZER ON VISION MULTIFUNCTION MACHINE

- Ifthemachineisintendedtooperateincloseproximityto

dangerousprecipices,itisabsolutelymandatory,before

beginningwork,tocordonadequatelyallthetraitsthatcan

leadtofallsfromthemeanduetoapossiblewrongmaneuver

bytheOperator.

- Nevertouchmovingpartsorinterposebetweenthemkeeping

asafedistance.

- Avoidparkingthemachineonslopes.Ifnecessary,secure

themachinewiththeparkingbrakeand,ifnecessary,use

suitablelogsorstonestobeplacedbetweenthegroundand

thetracks.

- Periodicallycheckthetightnessofthescrews,nutsandany

connections.

- Itisabsolutelyforbiddentoremoveortamperwiththesafety

devices.

- Refuelingwithfuelandoilshouldonlybecarriedoutwiththe

engineoffandnottoohot.Duringrefueling,donotsmokeor

approachnearre.Immediatelywipethefuelspillagebefore

startingtheengine.

- Itisveryimportanttokeepinmindthatroadanddirection/

brakingholdingcanbeinuenced,evennoticeably,bythe

presenceofastandardequipment.

- Itisforbiddentocarrypeopleonthemachine(inadditionto

thedriver).

-Keeptherollbarinverticalpositionduringthework.

Lowertherollbaronlyincasesofextremenecessityand

immediatelyreturnittothesafetypositionassoonasthe

conditionofnecessityhasceased.

2.3.2 FIRE-FIGHTING MEASURES

Boththemultifunctionmachineandtheatomizeraremanufac-

turedwithextensiveuseofpetroleum-derivedmaterials,and

thepresenceofvarioustypesofoilsandchemicalresidues

makethempotentiallyammable.

Itisadvisableforthepersonnelinchargeofthemachinetobe

awareofthemaininterventiontechniquesintheeventofare.

Allfuelsandmostlubricantsandhydraulicuidsareammable.

Donotsmokewhilerefuelingorrestoringuidlevels,donot

refuelclosetoopenamesanddonotpourthefuel.

Neverusegasoline,solventsorotherammableortoxicuids

forcleaningmechanicalparts,but,instead,useapproved

commercialsolventsthatarenon-ammableandnon-toxic.

Donotweldneartanks,pipes,cans,electricalcablesoramma-

blematerialsingeneral.Incaseofwelding,protectpotentially

ammablepartswithsuitableshields.

2.3.3 SAFETY DURING THE MAINTENANCE OF THE

MACHINE

- Machinemaintenancemustbeperformedonlywiththeengine

off,byqualiedpersonnelandfollowingtheinstructionsgiven

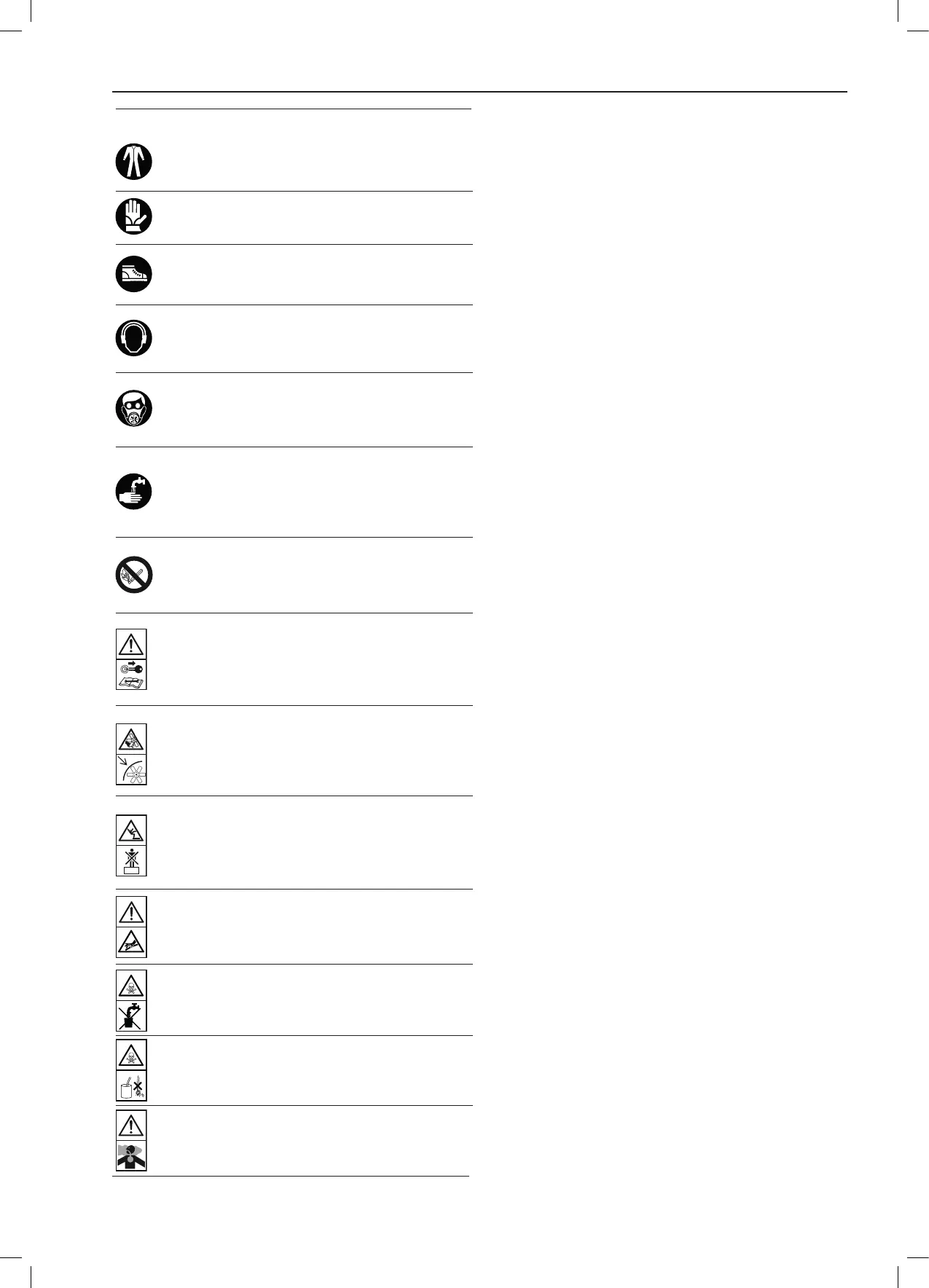

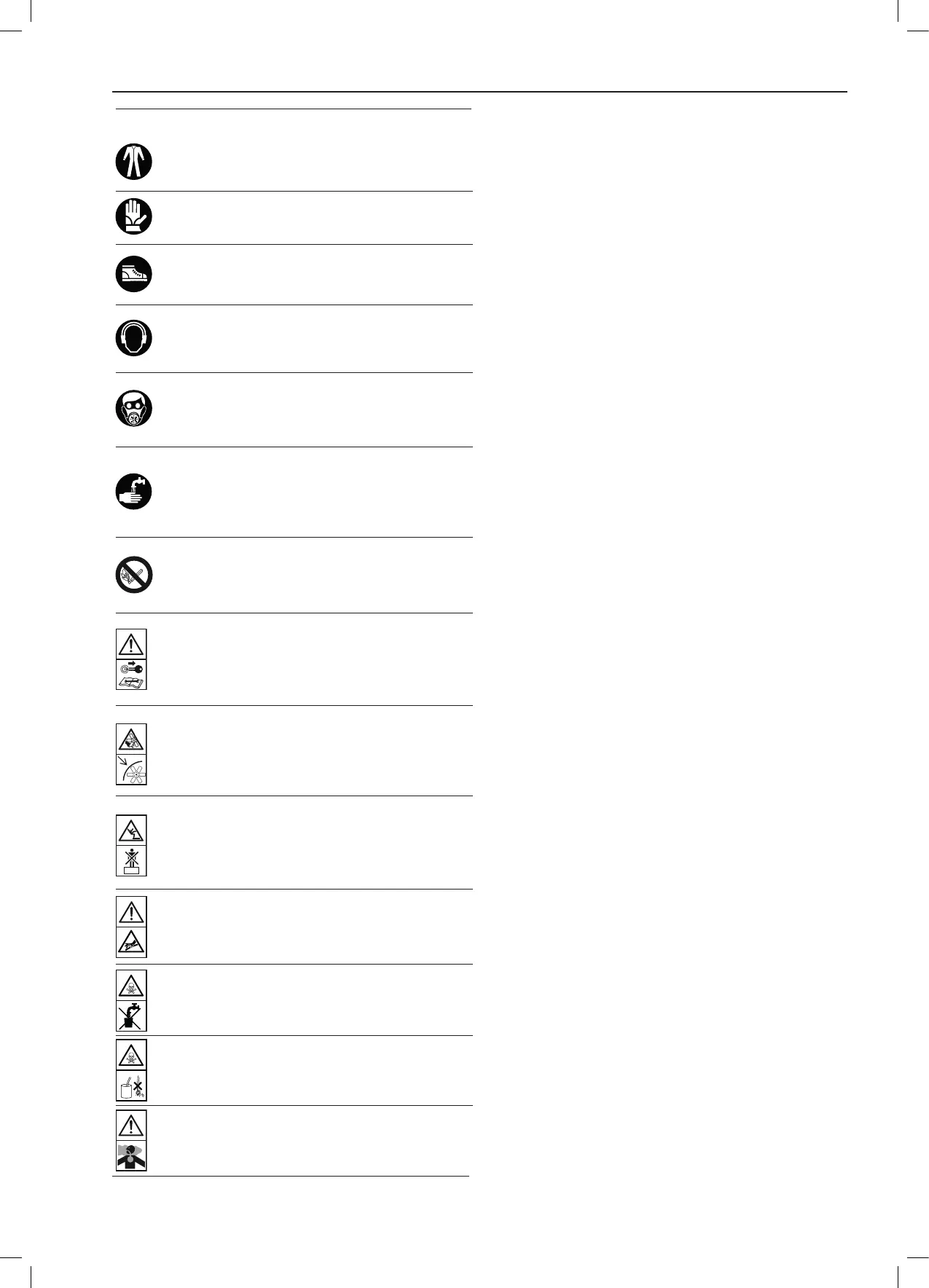

Key Fig. 5

1) Obligation to wear a protective suit.

2) Obligation to wear protective gloves.

3) Obligation to wear protective shoes.

4) Obligation to wear protective earmuffs during

operation.

5) Obligation to wear respiratory protection

mask during operation..

6) Hand washing tap. Hands should be

washed whenever they come into contact

with harmful products.

7) The use of open ames is prohibited.

Fire hazard.

8) B

efore performing any maintenance work,

stop the machine, switch off the engine and

read the instruction manual.

9) Do not remove the guards and do not

approach the moving parts.

10) It is absolutely forbidden to climb up to

strangers on the equipment, in addition to the

Operator. DANGER OF FALL.

11) Hoses with pressurized uid. Danger of

bursting if worn or broken.

12)

It is absolutely forbidden to drink treated liquids.

DANGER OF SERIOUS DAMAGE TO HEALTH.

13) Do not discharge residual liquids into the

enviroment

14) Danger of contact with fumes and toxic

Loading...

Loading...