53

Use and maintenance ATOMIZER ON VISION MULTIFUNCTION MACHINE

4.1.5 FAN GROUP (Fig. 11)

TheatomizerONhasafanathighspeedrotationprotected

byagrid(1Fig.11).

It is necessary topay attention to theeffectsthat this can

cause:suchastheaspirationandprojectionofforeignbodies

that,althoughsmall,canbedangerousespeciallyfortheeyes

andtheface.

Intheupperpartofthefantherearetwodeectors(oneon

therightandoneontheleft-3Fig.11),whichcanbeadjusted

usingthetwoknobs(2Fig.11)andwhichareusedtodene

theairowdirectionandthereforetodirectthesprayedpro-

ductmoreprecisely.Inthelowerpartofthedeliveryportofthe

fantherearetwoxedowdirectionconveyors(4Fig.11).

4.2 BEFORE USE

WARNING: Before starting up the machine, the

Operator must have read and understood all the

sections of this manual (as well as the machine

manual) and in particular what is reported in

«Section 2» dedicated to safety. Furthermore,

before starting work, check that the machine is

in order and that all the items subjected to wear

and deterioration are fully efcient.

4.2.1 PREPARATION AND FILLING OF THE

PRODUCT TANK

DANGER: Chemicals are harmful by inhalation and

contact. Always use protective clothing. In this

regard, carefully read the paragraph “2.4 Safety

during the use of plant protection products”.

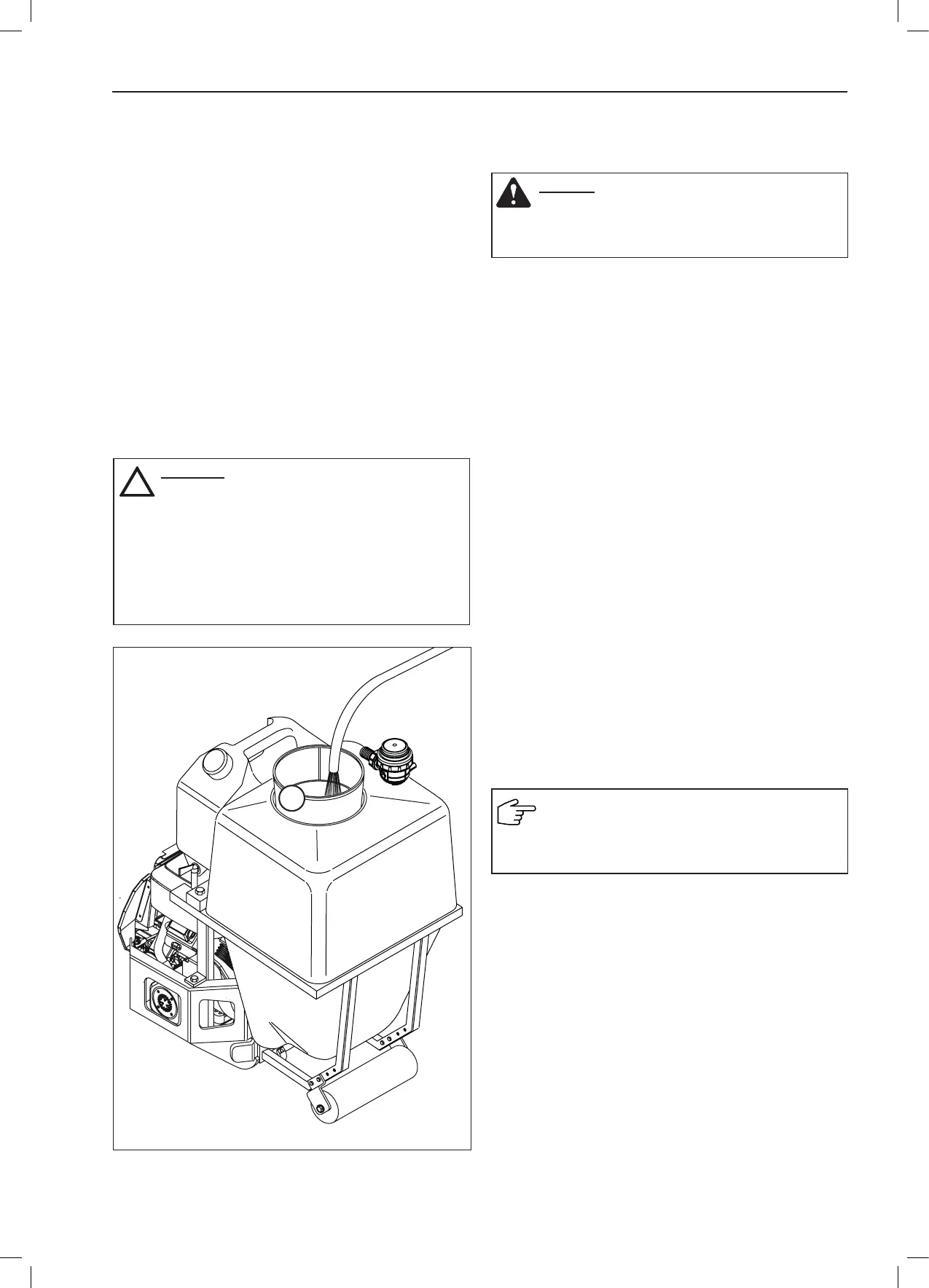

4.2.2 FILLING THE TANK

Beforelling,makesurethetankisperfectlyintactandinpar-

ticularthatallpipeconnectionsarewellxed.

Alsomakesurethatthelter(1Fig.9)iswellcleaned.Ifne-

cessary,cleanit.

Itispossibletohighlightablockageduetotheirregularopera-

tionofthepressuregauge(5Fig.10).

Thetankislledthrough the hatch with thepresenceofa

basketlter(1Fig.12)with1mmmesh.Allthismustbecar-

riedoutfollowingtheimmersionofthellingtubeintheliquid

insidethetank,withoutllingthetanktotheedgeofthehatch.

Thesprayertanksforcropprotectiontreatments,inconsidera-

tionoftheprotectionofpeople,animalsandtheenvironment,

mustbelledonlyindirectlywithcleanwaterandonlywithfree

fallfromwaterpipes.

Thellingtubemustnevercomeintocontactwiththeliquid

insidethetankandthereforemustalwayslet thewaterfall

overtheupperedgeofthellingopeningandthroughthelter

therein.

Thetankhasagraduatedband(2Fig.9)whichshowsthe

exactamountofliquidinsidefortransparency.Saiddetection

specieswhetherthetankisonalevelsurface;thetotaleffec-

tivecapacitycoincideswiththelastnumberatthetop.

Filling must be carried out with the machine on

a leveled surface. At the workplace, before the

operation, the doses or mixtures to be poured

into the tank must be prepared.

4.2.3 MIXING

Theproductcanbemixedusingtheagitatorplacedinsidethe

tank(3Fig.9)beforeandduringtreatment.Goodmixingand

agitationareatthebaseofacorrectdistributiononthecrop.

Mixtheactiveingredientmanually beforeintroducingitinto

thetank.

Tooperateonlytheagitator,itisnecessarytoturnthetractor

powertake-offtomediumspeed,keepingonlytheagitatortap

openandmaintainingthepressurebetween10and25bars,

veriablebythepressuregaugelocatedinthecontrolunit.In

Fig. 12 - Introduction of water in the tank

1

Loading...

Loading...