54

Use and maintenance ATOMIZER ON VISION MULTIFUNCTION MACHINE

caseofinterruptionoftheactivityduringtheuseoftheato-

mizer,keeptheagitationuntilthetreatmentisresumed.Ifit

issuspended,shakeagainthemixtureremaininginthetank.

During product handling and mixing, the use of suitable

guardssuchasrubbergloves,maskorgoggles,overalls,etc.

is mandatory.

4.2.4 PRELIMINARY WORKS THAN THE

TREATMENT

The Operator shall:

- Makesurethattheconditionsofthecrops,thedevelopment

ofthediseaseortherequirementsofpreventionjustifythe

treatment.

- Makesureof the expectedweatherconditions for allthe

timenecessarytocarryoutthetreatment.

- Avoid, if possible, the spraying in conditions of sensitive

windbecausethesprayedmixturecanbedispersedoutside

thetarget(drift).

Itisadvisabletosuspendthetreatmentwhenthewindspeed

exceeds10Km/h(3m/s).

In the need to operate, we suggest to:

- Increasethesizeofthedrops,thusadjustingtheatomizer

appropriately.

- Checkthatmixtureswithmoreproductsarephysically,che-

micallyandbiologicallycompatiblewitheachother;consult

theSeller/Agent.

- Calculatetheexactamountofproductneededfortreatment

andestablishtheamountofwatertobeusedintheopera-

tion.

- Checkthattheproductisavailableinsufcientquantityto

completethework.

DANGER: Carefully read the instructions for use

in the product containers, to check the conditions

of use, the correct dosage and the deadlines.

4.2.5 QUANTITY OF CHEMICAL PRODUCT TO

BE INTRODUCED IN THE TANK

Referring to the delivery table per hectare, obtain the ne-

cessary parameters to adjust the machine and determine

the exact dose of product to be used for each lling. It is

possibletoestablishthequantityofchemicalproducttobe

insertedinthetank,applyingthefollowingformula:Tank volu-

me x dose/ha: l/ha = quantity of product to be inserted in

the tank. Example:Knowingforexamplethecapacityofthe

tank(i.e.150l),thebaseofchemicalproducttobedispensed

perhectare(i.e.3.5l/ha)isthequantityofliquidtobedistri-

buted(i.e.150l/ha):150 x 3.5: 150 = 3.5 (liters of chemical

product to be inserted in the tank).

4.2.6 ADJUSTMENT CRITERIA AND CHOICE

OF WATER VOLUMES

Onthebasisofsomeparametersreferringtothecroptobe

treated,tothetractorandtotheatomizer,itispossible,with

theaidofthebelowtables,todeterminetheoperatingspeed,

theowrateandthetimerequiredforthetreatment.

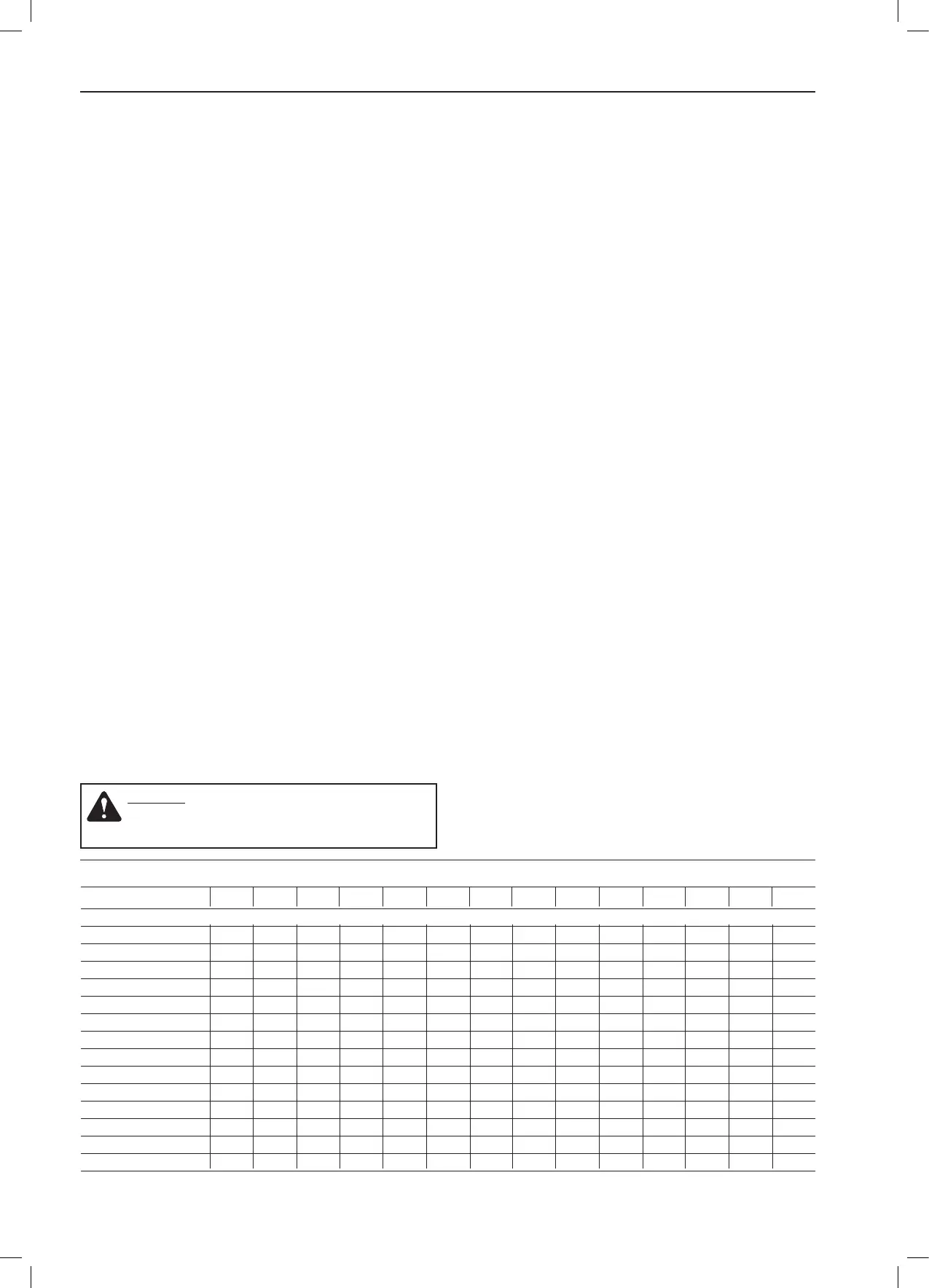

Fromtable«1»,dependingontheinter-rowdistanceandtrac-

torspeed,itisobtainedthetimeinminutestosprayonehec-

tareoflandbyintersectionoflinesandcolumns.

Thus,obtainedtheworkingtimeinminutes/hectare,fromthe

table «2»thevalueinlitersperminutetobesuppliedonthe

cropisobtainedbyintersectionbetweenlineandcolumn,ac-

cordingtothelitersperhectarethatoneintendstodistribute.

Havingthusobtainedtheoverallowrate,dividingthisvalue

bythenumberofnozzlesmountedonthemachinegivesthe

necessaryowrateofeachindividualnozzle.Thisvaluegives

theoperatingpressuretobesetontheregulatortoobtainthe

correctquantityofliters/minutepreviouslytakenfromtable2.

Feed speed 2 2,5 3 3,5 4 4,5 5 5,5 6 6,5 7 8 9 10

Inter-row distance MINUTES / HECTARE

2,0 150 120 100 86 75 67 60 55 50 46 43 38 33 30

2,5 120 96 80 69 60 53 48 44 40 37 34 30 27 24

3,0 100 80 67 57 50 44 40 36 33 31 29 25 22 20

3,5 86 69 57 49 43 38 34 31 29 26 24 21 19 17

4,0 75 60 50 43 38 33 30 27 25 23 21 19 17 15

4,5 67 53 44 38 33 30 27 24 22 21 19 17 15 13

5,0 60 48 40 34 30 27 24 22 20 18 17 15 13 12

5,5 55 44 36 31 27 24 22 20 18 17 16 7 12 11

6,0 50 40 33 29 25 22 20 18 17 15 14 7 11 10

6,5 46 37 31 26 23 21 18 5 15 14 13 14 10 9

7,0 43 34 29 24 21 19 17 5 14 13 12 13 10 9

8,0 38 30 25 21 19 17 15 16 13 12 11 5 8 8

9,0 33 27 22 19 17 15 13 14 11 10 10 5 7 7

10,0 30 24 20 17 15 13 12 11 10 9 9 11 7 6

TABLE 1

Loading...

Loading...