18

EN

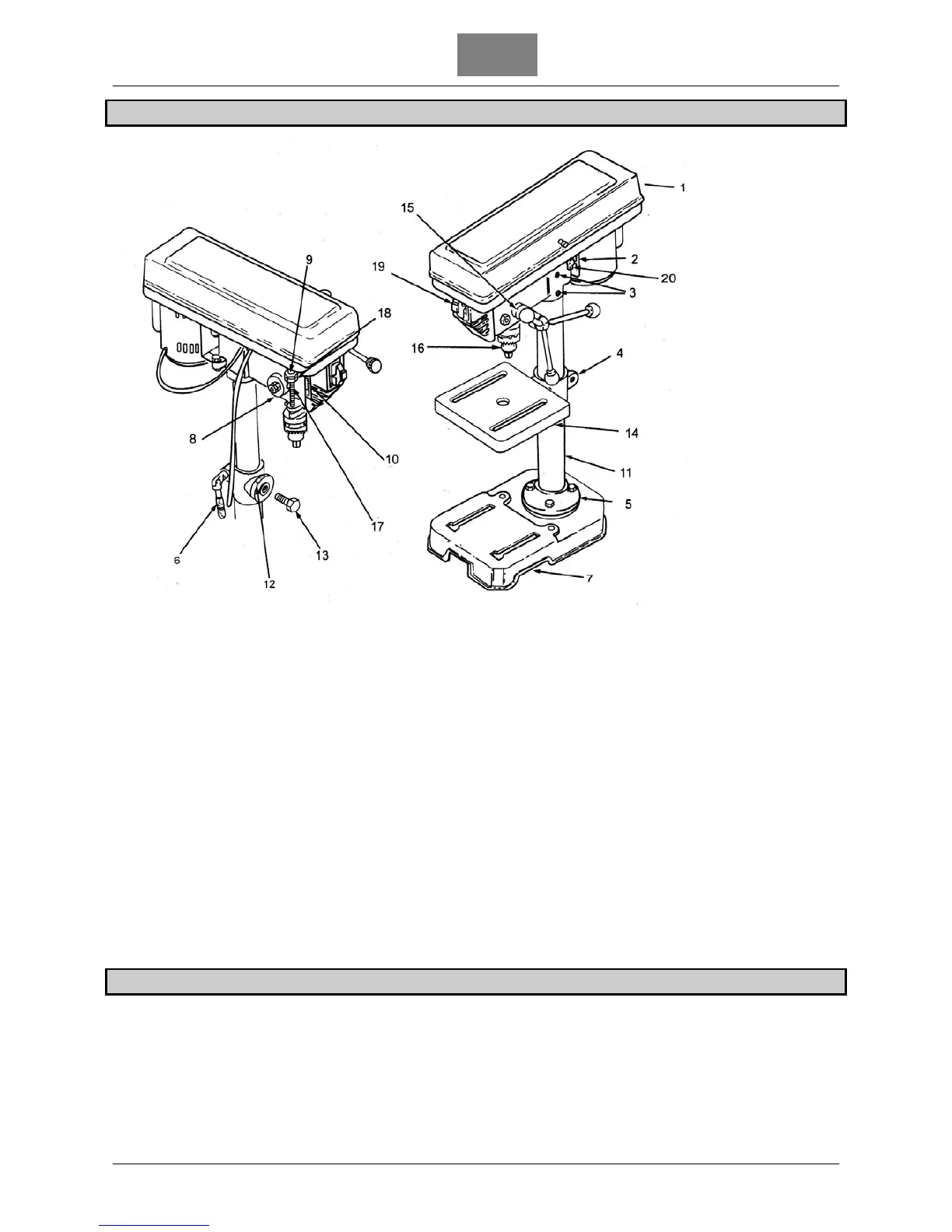

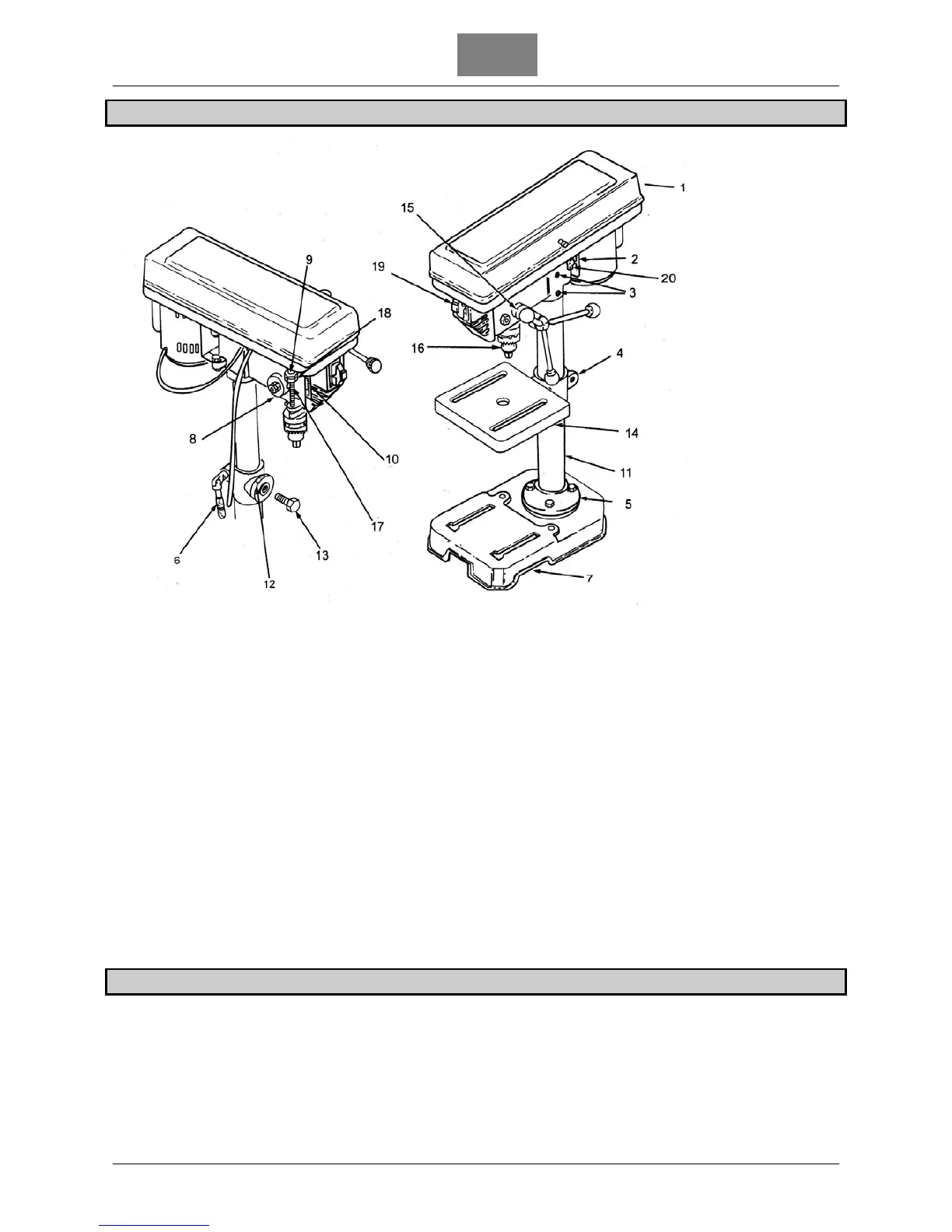

LOCATION AND FUNCTION OF CONTROLS

1. Pulley guard

2.

Belt tension lock handle

3.

Hea

d lock set screws

4.

Suppo

rt - table

5.

Column - support

6.

Suppo

rt – lock

7.

Base

8.

Spring cap

9.

Depth scale i

ndicator

10.

Depth scale

11.

Column

12.

Bevel scale

13.

Table lock se

t screws

14.

Table

15.

Feed handles

16.

Chu

ck

17.

Feed stop ro

d

18.

S

top nuts

19.

Switch

20.

Spring motor stop

DRILLING SPEED

Factors entailing better results with drill presses are the type of material, hole’s size, type of bit or miller and

cutting quality desired. The smaller the bit is, the faster the necessary speed must be. Speed must be higher

when processing soft materials than hard metals. Use the recommended speed for the bit you are using and for

the material to be cut

The chuck of this drill press can turn at 5 different speed levels: from 580 to 2650 RPM. You can obtain the

lowest speed by placing the belt on the smaller step of motor’s pulley and on the biggest of spindle’s pulley.

Loading...

Loading...