12

Using a flexible connection

This appliance is approved for connection with a flexible hose, which complies with the AS/NZS

1869 (Australian Approved), 10mm ID, class B or D, between 1-1.2m long. Connection shall be in

compliance with AS/NZS 5601 for a high level connection. The hose should not be subjected to

abrasion, kinking or permanent deformation and should be able to be inspected along its entire length.

Unions compatible with the hose fittings must be used and connections tested for gas leaks. The fixed

consumer piping outlet should be at approximately the same height as the cooker connection point,

pointing downwards and approximately 150mm to the side of the cooker. The hose should be clear of

the floor when the cooker is in the installed position.

When installing the hose restraint device, the appliance anchor point is the rear panel.

Using a Copper Pipe connection

The cooker must be connected to the gas supply with upstream connection of an isolation valve in

accordance with the respectively valid regulations. We recommend that the isolation valve be fitted

prior to the cooker to enable isolation of the cooker from the gas supply. The valve must be easily

accessible at all times. To find out the gas type factory settings, see label on the rear of the appliance.

Test the operation of the cooker before leaving

Note: These burners have no aeration adjustment.

Check correct operation of the ignitions system and operation of the regulator and operation of the

burners individually and in combination. Burner flames should be clear blue, with no yellow tipping.

If the burners show any abnormality check that the burners are correctly located. If satisfactory

performance cannot be obtained, contact service.

Important

Before leaving instruct the owner in the use of the

cooker it should be expressly noted that we cannot

accept any liability for direct or indirect damage

caused by wrong connection or improper installation.

When being repaired, the appliance must always be

disconnected from the mains supply; if required,

notify our customer service.

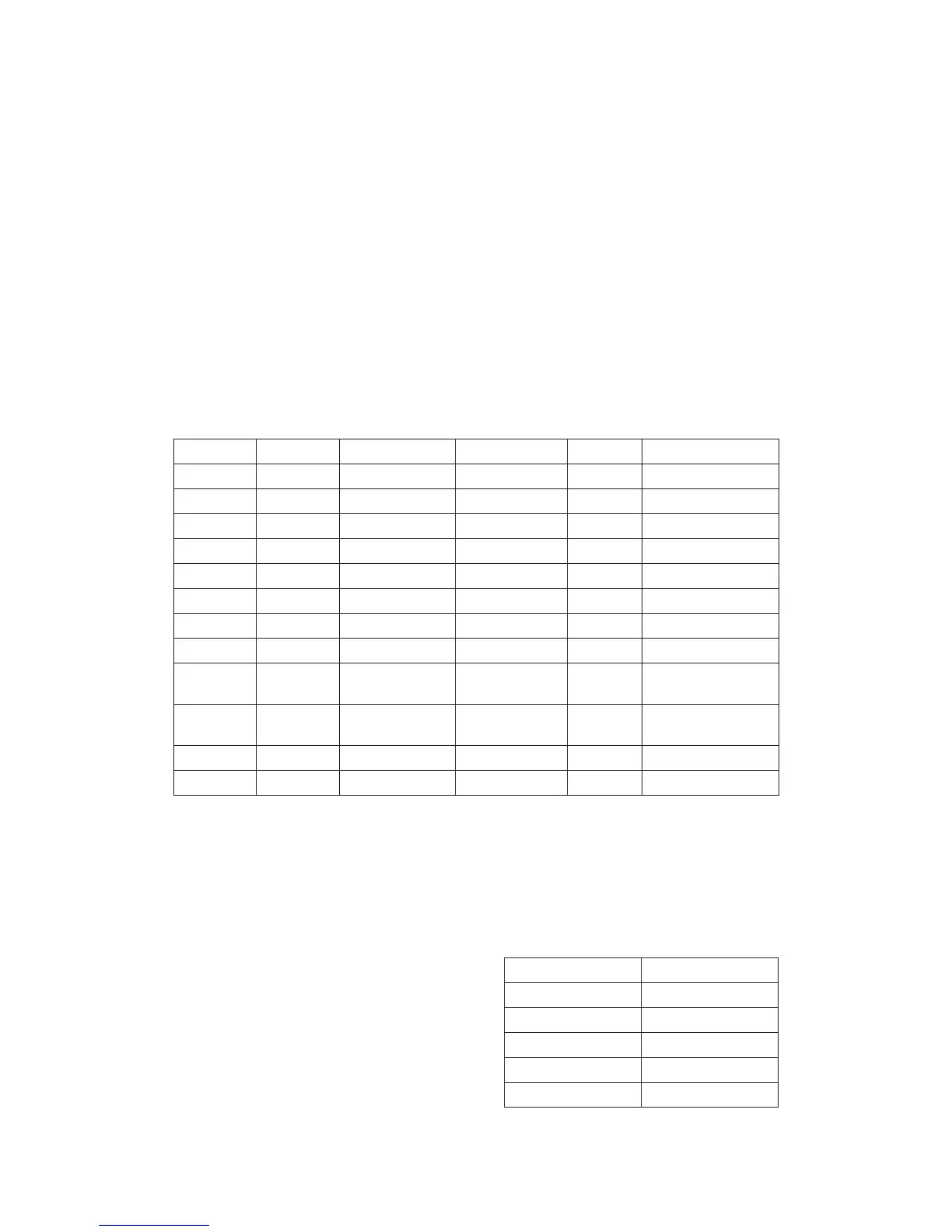

Burners Gas type Pressure (kPa) Injector (mm) Mj/hr By-pass size (mm)

Small Natural 1.00 0.90 4.00 0.30 regulated

Small ULPG 2.75 0.54 4.00 0.30

Medium Natural 1.00 1.18 7.00 0.36 regulated

Medium ULPG 2.75 0.70 7.00 0.36

Large Natural 1.00 1.55 11.50 0.52 regulated

Large ULPG 2.75 0.92 11.50 0.52

Wok Natural 1.00 1.80 14.50 0.65 regulated

Wok ULPG 2.75 1.02 14.50 0.65

Wok 2way Natural 1.00

Ex. 1.80

int. 0.50

17.50

Ex. 0.65 reg.

int. 0.34 reg.

Wok 2way ULPG 2.75

Ex. 1.02

int. 0.50

17.50

Ex. 0.65 reg.

int. 0.34 reg.

Oven Natural 1.00 1.95 16.50 0.62 regulated

Oven ULPG 2.75 1.10 16.50 0.62

TABLE N°1

Adaption to various types of gas

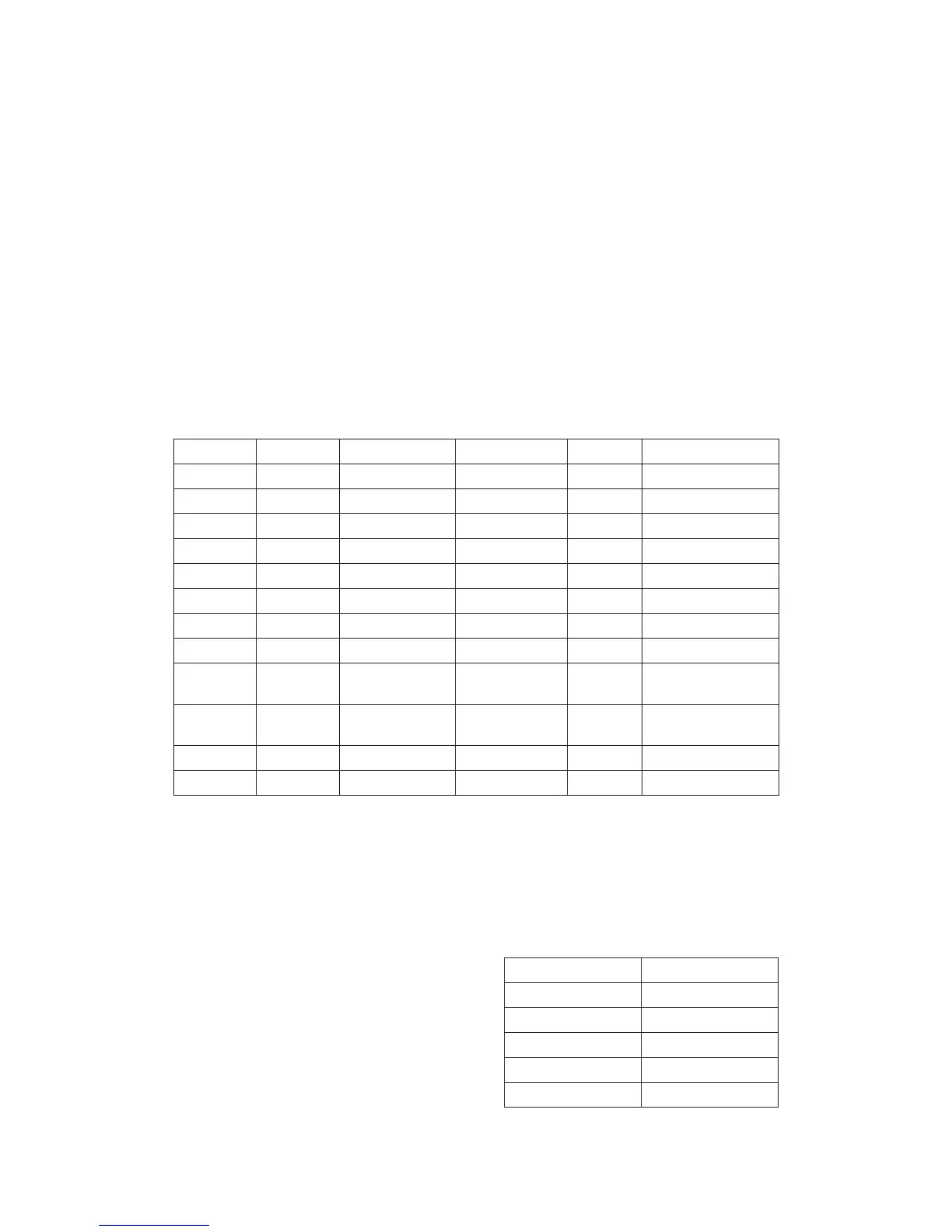

Burners Dimensions (mm)

Auxiliary ø50

Semi-rapid ø70

Rapid ø95

Wok ø125

Wok 2 ways ø135

TABLE N°2: GAS BURNER DIMENSION

Loading...

Loading...