MODEL: PFR2190

TOOL USE AND CARE

Know this tool. Read manual carefully, learn

its applications and limitations, as well as the

specific potential hazards related to this tool.

Use only fasteners that are recommended

for your models. Do not use the wrong

fasteners or load the fasteners incorrectly.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tool's

operation. If damaged, have the tool serviced

before using. Many accidents are caused by

poorly maintained tools.

Maintain tools with care. Keep tool clean. A

properly maintained tool, reduces the risk of

binding and is easier to control.

Store tools out of the reach of children and

other untrained people. Tools are dangerous

in the hands of untrained users.

Check operation of the tool before use. DO

not use the tool if the workpiece contact

mechanism is not working correctly as

accidental driving of a fastener may occur.

Do not use tool if trigger does not actuate

properly. Any tool that cannot be controlled

with the trigger is dangerous and must be

repaired.

Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding a tool by hand or

against the body is unstable and may lead to

loss of control.

Keep the tool and its handle dry, clean and

free from oil and grease. Always use a clean

cloth when cleaning. Never use brake fluids,

gasoline, petroleum—based products, or any

Strong solvents to clean your tool.

Do not use the tool as a hammer.

Never use this tool in a manner that could

cause a fastener to be directed toward

anything other than the workpiece.

Always carry the tool by the handle. Never

carry the tool by the air hose.

Do not use the tool if it leaks air or does not

function properly.

Do not operate the tool if it does not contain

a legible warning label.

TOOL SERVICE

Use only accessories that are identified by

the manufacturer for the specific tool model.

Use of unauthorized parts or failure to

follow maintenance instructions may

create a risk of injury.

Use only the lubricants supplied with the

tool or specified by the manufacturer.

Tool service must be performed only by

qualified repair personnel.

OPERATION

Do not drive fasteners near edge of material.

The workpiece may split causing the fastener or

ricochet, injuring you or people around.

Do not carry the tool from place to place

holding the trigger. Accidental discharge

could result. Choice of triggering method is

important. Check manual for triggering options.

During normal use the tool will recoil

immediately after driving a fastener. This is

a normal function of the tool. Do not attempt to

prevent the recoil by holding the tool against the

work. Restriction to the recoil can result in a

second fastener being driven from the tool. Grip

the handle firmly and let the tool do the work.

Failure to heed this waming can result in

serious personal injury.

Do not drive fasteners on top of other

fasteners or with the tool at an overly steep

angle as this may cause deflection Of

fasteners which could cause injury.

Do not actuate the tool unless you intend to

drive a fastener into the workpiece.

Always handle the tool with care:

Respect the tool as a working implement.

Never engage in horseplay.

Never pull the trigger unless nose is directed

toward the work.

Keep others a safe distance from the tool

while tool is in operation as accidental

actuation may occur, possibly causing injury.

AIR SUPPLY AND CONNECTIONS

The connector on the tool must not hold

pressure when air supply is disconnected. If

an incorrect fitting is used, the tool can remain

charged with air after disconnecting and thus

will be able to drive a fastener even after the air

line is disconnected, possibly causing injury.

MODEL: PFR2190

Do not use oxygen, combustible gases or

bottled gasses as a power source for this

tool. Explosion may occur, causing injury or

death.

Do not connect with an air compressor

which can potentially exceed 200 Psi.

As tool may burst, possibly causing injury.

Always disconnect air resource:

Before making adjustments.

When servicingthe tool.

• When clean a jam.

When tool is not in use.

When moving to a different work area, as

accidental actuation may occur, causing injury.

LOADING TOOL

Do not load the tool with fasteners when

any one of the operating controls is

activated.

Never place a hand or any part of body in

fastener discharge area of tool.

Never point tool at anyone.

Do not pull the trigger or depress the

workpiece contact as accidental actuation

may occur, possibly causing injury.

A WARNING:

The warnings and precautions discussed

above cannot cover all possible

conditions and situations that may occur.

It must be understood by the user that

common sense and caution are factors

which cannot be built into this product,

but must be supplied by the user.

UNPACKING

This tool has been shipped completely

assembled.

Make sure that all items listed in the packing

list are included.

Carefully remove the tool and any

accessories from the box.

Inspect the tool carefully to make sure no

breakage or damage occurred during

shipping.

Do not discard the packing material until you

have carefully inspected and satisfactorily

operated the tool.

tf any parts are damaged or missing, please

call 1-888-669-5672.

REEman

PACKING LIST

Framing nailer

Carrying case

Air connector

Adjustment tools

Lubricating Oil

Instruction manual

Safety goggles

Anti—dust cap

Framing nailer

A WARNING:

If any parts are missing do not operate

this tool until the missing parts are

replaced. Failure to do so could result in

possible serious personal injury.

A WARNING:

Do not attempt to modify this tool or

create accessories not recommended for

use with this tool. Any such alteration or

modification is misuse and could result

in hazardous condition leading to

possible serious personal injury.

FEATURES

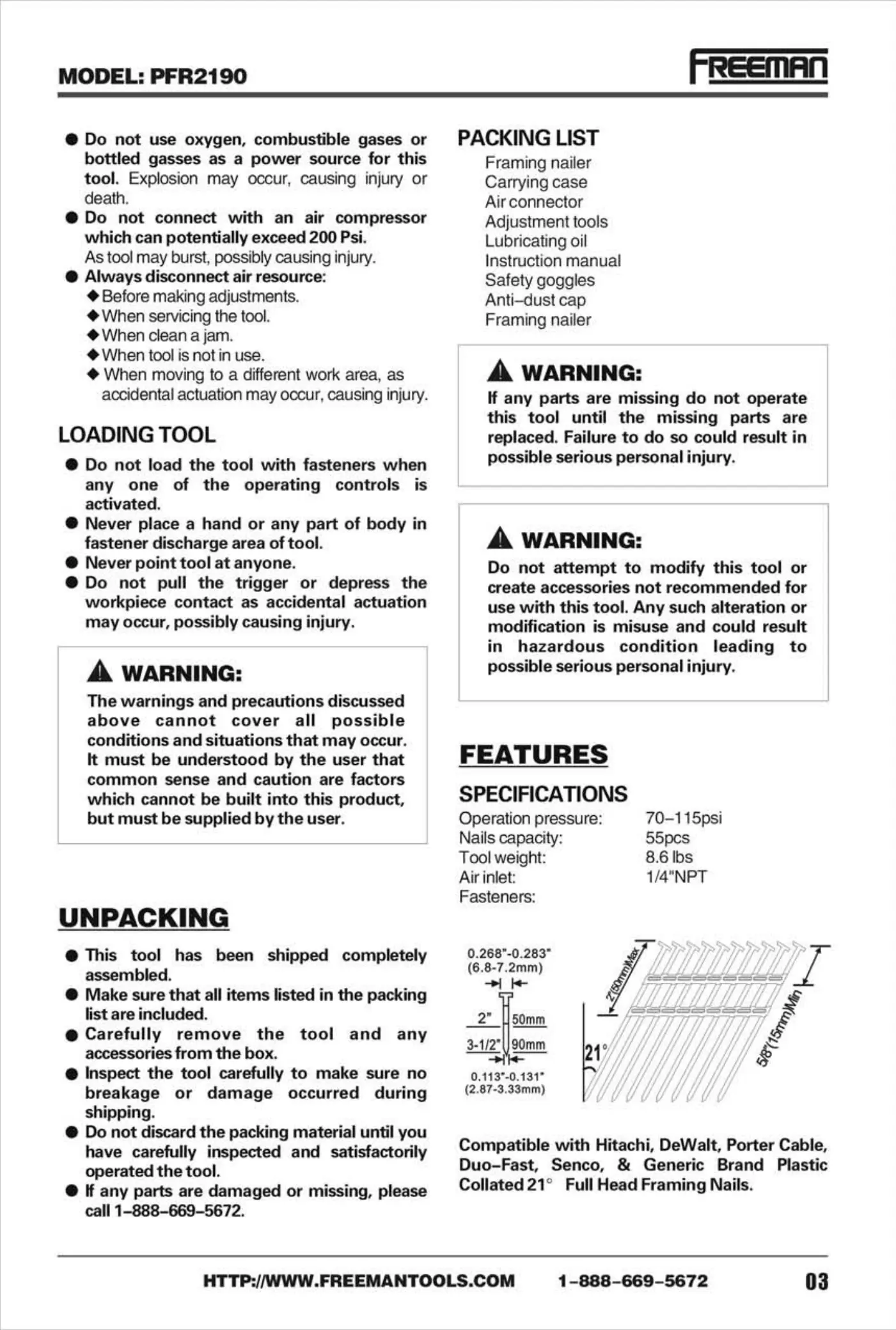

SPECIFICATIONS

Operation pressure:

Nails capacity:

Tool weight:

Air inlet:

Fasteners:

0.268"-0.283•

(6.8-7.2mm)

2 • 50mm

3-11? 90mm

0.113%0.131•

(2.87-3.33mm)

70-115psi

55pcs

8.6 lbs

I /4"NPT

Compatible with Hitachi, DeWalt, Porter Cable,

Duo—Fast, Senco, & Generic Brand Plastic

Collated 210 Full Head Framing Nails.

02

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

03

Loading...

Loading...