MODEL: PFR2190

FEATURES

3600 ADJUSTABLE EXHAUST

Allows user to direct air away from debris.

OIL-FREE DESIGN

For less maintenance.

e ONE PIECE DRIVER BLADE

For increased durability.

ANODIZED ALUMINUM CYLINDER

MAGAZINE

For long lasting durability.

COMFORT-GRIP HANDLE

For increased comfort and control.

MAGNESIUM BODY

Light—weighttool great for extended use.

AIR FILTER

Keeps interior components debris

extending tool life.

DUAL-MODE TRIGGER

AND

free,

REErnan

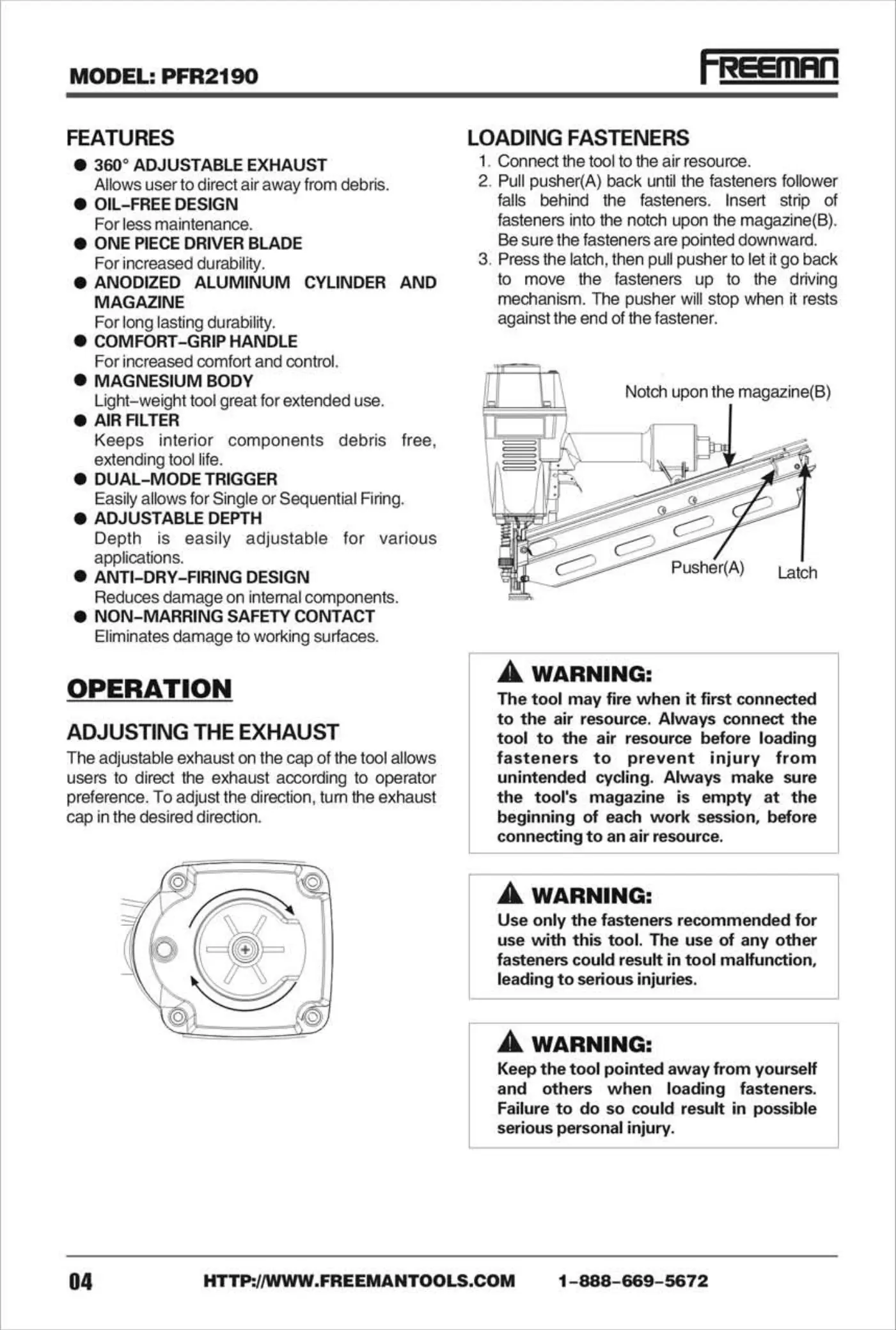

LOADING FASTENERS

1. Connect the tool to the air resource.

2. Pull pusher(A) back until the fasteners follower

falls behind the fasteners. Insert strip of

fasteners into the notch upon the magazine(B).

Be sure the fasteners are pointed downward.

3. Press the latch, then pull pusher to let it go back

to move the fasteners up to the driving

mechanism. The pusher will stop when it rests

against the end of the fastener.

Notch upon the magazine(B)

MODEL: PFR2190

A WARNING:

Never load fasteners with the workpiece

contact or trigger activated. Doing so

could result in possible serious personal

injury.

UNLOADING FASTENERS

Unloading is the reverse of loading, except always

disconnect the air resource before unloading.

A WARNING:

Always unload all fasteners before removing

Easily allows for Single or Sequential Firing.

ADJUSTABLE DEPTH

Depth is easily adjustable for various

applications.

• ANTI-DRY-FIRING DESIGN

Reduces damage on intemal components.

• NON-MARRING SAFETY CONTACT

Eliminates damage to working surfaces.

OPERATION

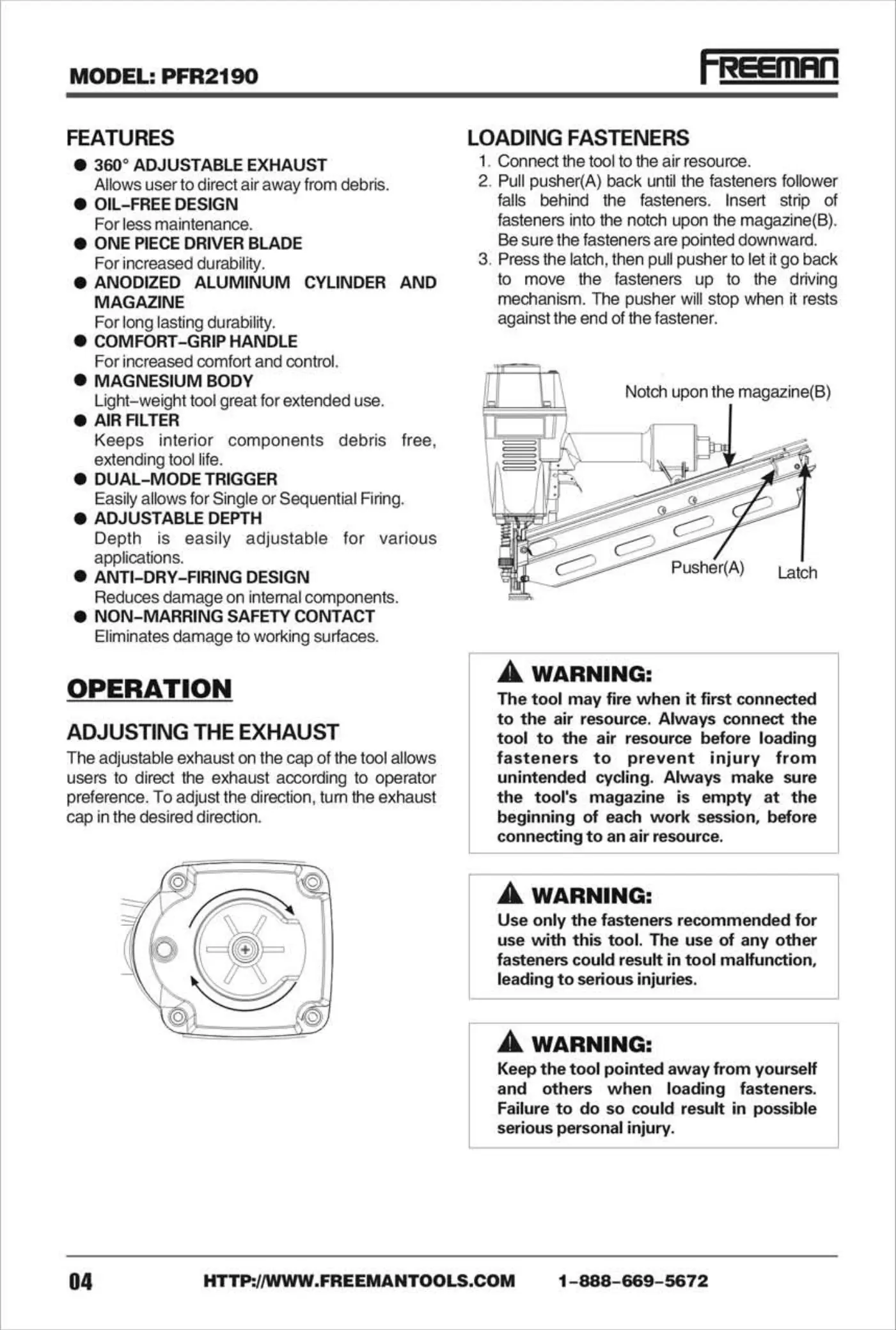

ADJUSTING THE EXHAUST

The adjustable exhaust on the cap of the tool allows

users to direct the exhaust according to operator

preference. To adjust the direction, tum the exhaust

cap in the desired direction.

Pusher(A)

A WARNING:

Latch

tool from service.

A WARNING:

Always disconnect the air resource

unloading.

CLEARING JAMS

before

The tool may fire when it first connected

to the air resource. Always connect the

tool to the air resource before loading

fasteners to prevent injury from

unintended cycling. Always make sure

the tool's magazine is empty at the

beginning of each work session, before

connecting to an air resource.

A WARNING:

Use only the fasteners recommended for

use with this tool. The use of any other

fasteners could result in tool malfunction,

leading to serious injuries.

A WARNING:

Keep the tool pointed away from yourself

and others when loading fasteners.

Failure to do so could result in possible

serious personal injury.

Occasionally, a fastener may become jammed in

the firing mechanism of the tool, making the tool

inoperable. To rernove a jammed fastener, follow

the steps below:

1. Disconnect the tool from air resource.

2. Remove fasteners from the tool. Failure to do

so will cause the fasteners to eject from the front

of the tool.

3. Pull the jamrned fastener out from the nose, use

pliers or a screwdriver if required to clear the

jammed fastener. Using caution not to bend or

damage the driver blade.

4. Reconnect the tool to the air resource.

5, Reload the tool with fasteners.

A WARNING:

Make sure there is no fastener

magazine before clearing a jam.

in

REEman

A WARNING:

Disconnect the tool from the air source

whenever clearing a jam. After

disconnecting the tool from the air

compressor, there should still be enough

air pressure to fire the tool. After the air

hose is disconnected, always fire the tool

into scrap wood repeatedly to make sure

all of the compressed air is expended.

NO-MARRING PAD

The no—marringpad attached the nose of the tool

helps prevent marring and denting when working

with softer woods.

A WARNING:

Disconnect the tool from the air resource

before removing or replacing the no—

marring pad or replacing the no—marring

pad. Failure to do so could result in serious

personal injury.

SETTING THE AIR PRESSURE

The amount of air pressure required depends on

the size of the fasteners and the workpiece material.

Begin testing the depth Ofdrive by driving a test nail

into the same type of workpiece material used for

the actual job.

Drive a test fastener with the air pressure set at 90—

95psi. Raise or lower the air pressure to find the

lowest setting that will perform the job with

consistent results.

It may be possible to achieve the desired depth with

air pressure adjustments alone.

DEPTH ADJUSTMENT

The driving depth of the fasteners are adjustable.

To adjust the depth, use the drive depth adjustment

wheel(C) on the tool.

I. Disconnect the tool from the air resource.

2. Turn the depth wheel left or right to change the

driving depth.

3. Reconnect the tool to the air resource.

4. Drive a test nail after each adjustment until the

desired depth is set.

04

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

HTTP://WWW.FREEMANTOOLS.COM

1-888-669-5672

05

Loading...

Loading...