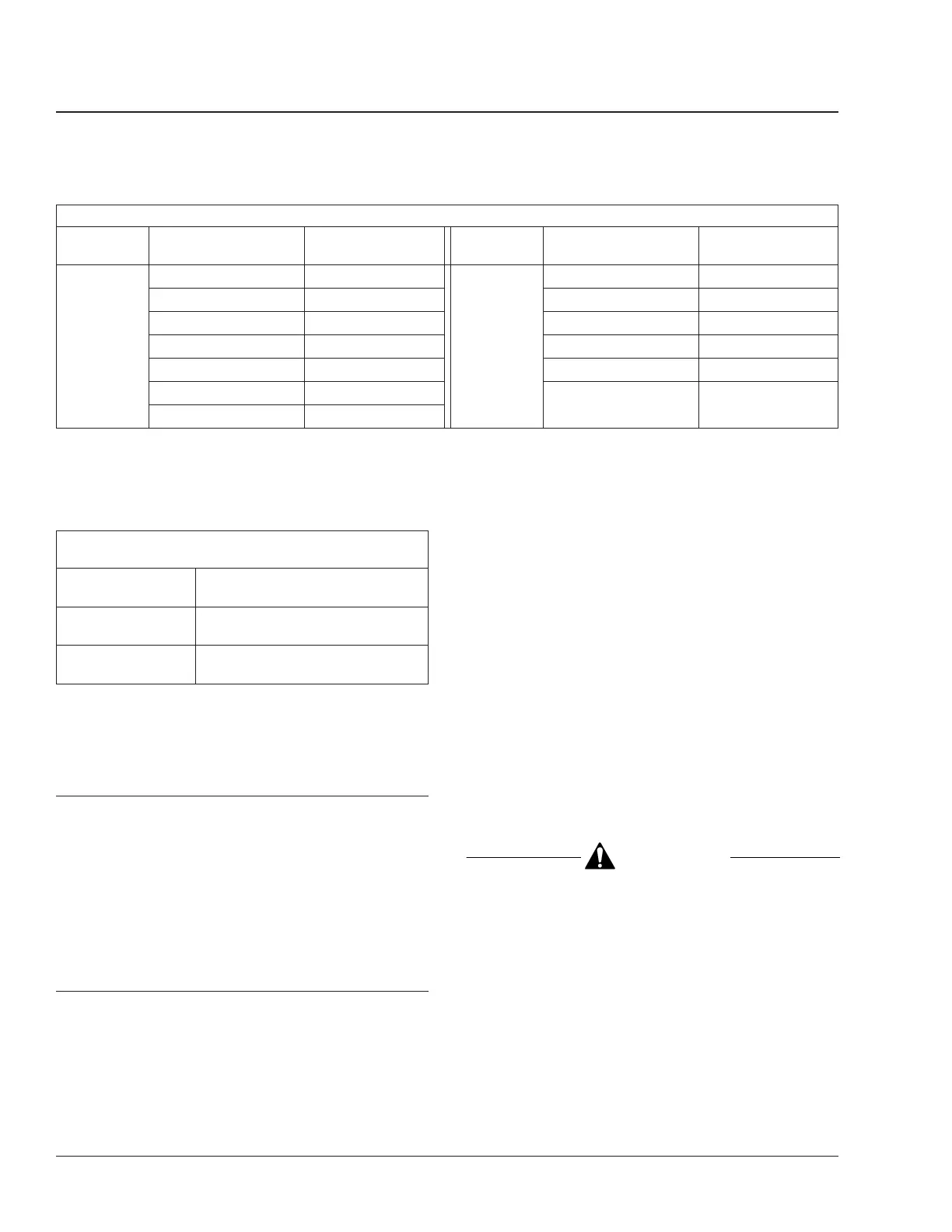

Rockwell Drive Axle Lubricant Capacities, Single Axles

Axle Type Axle Model

Capacity

*

pints (liters)

Axle Type Axle Model

Capacity

*

pints (liters)

Single

†

RS–13–120 16 (7.6)

Single

†

RS–19–220 31 (14.7)

RS–15–120 16 (7.6) RS–21–145 32 (15.1)

RS–15–210 16 (7.6) RS–21–160 39.5 (18.7)

RS–17–140 31 (14.7) RS–21–230 39 (18.5)

RS–17–145 33.6 (15.9) RS–23–160 42 (19.9)

RS–17–220 31 (14.7)

RS–23–240

45 (21.3)

RS–19–145 34.4 (16.3)

*

Quantities listed are approximate and include 1 pint (0.5 liter) for each wheel end and with the drive pinion at 3 degrees.

†

Single drive axles equipped with traction equalizers may require a "friction modifier" to correct a slip-stick condition, as described in the vehicle driver’s

manual. Rockwell’s experience shows that the following additives perform adequately: Add Elco No. 2 Friction Modifier (1 ounce [30 ml] of additive for each 1

pint [0.5 liter] of lube capacity) or Lubrizol No. 797 or 762 (1 ounce [30 mL] of additive for each 1 pint [0.5 liter] of lube capacity).

Table 2, Rockwell Drive Axle Lubricant Capacities, Single Axles

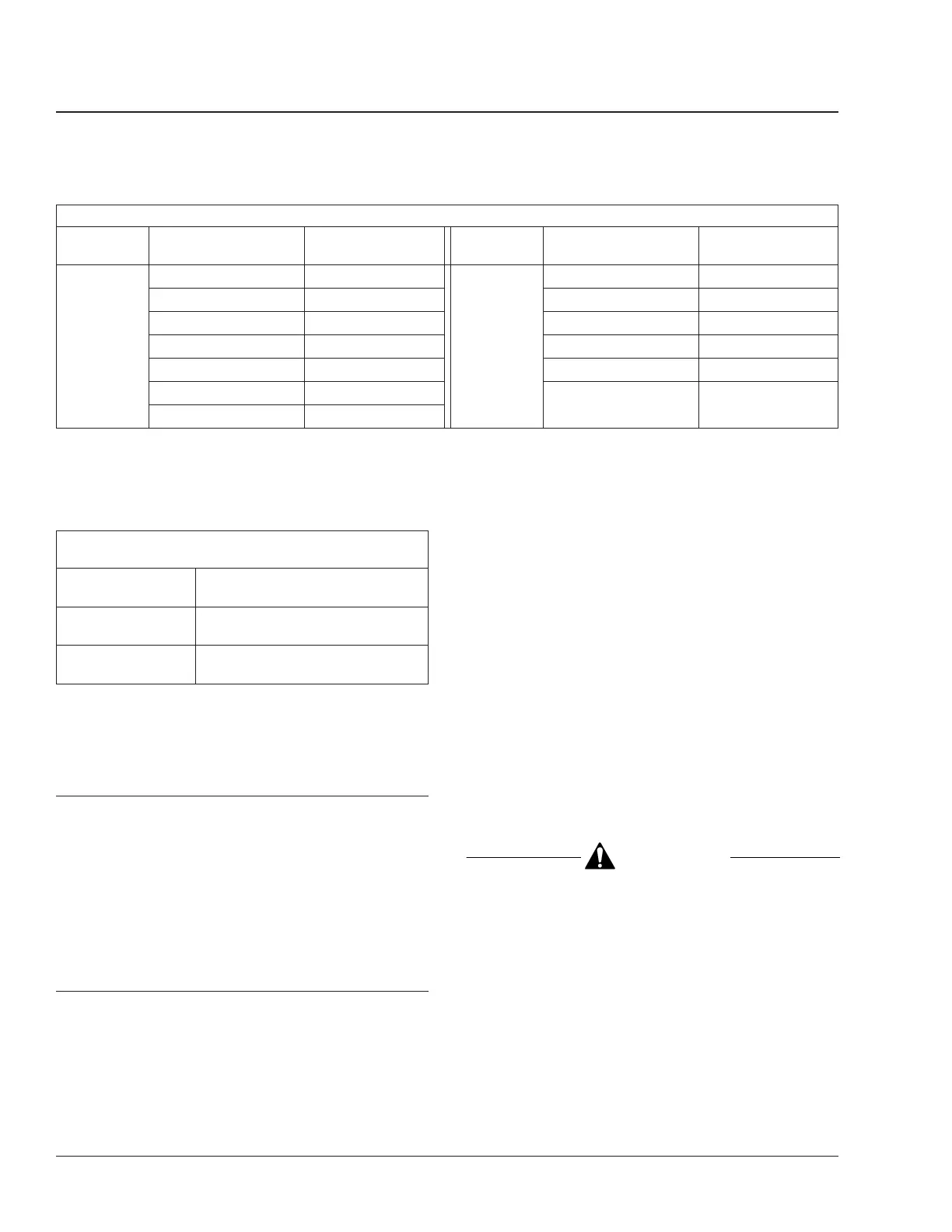

Rockwell Drive Axle Lubricant

Capacities, Tandem Axles

Axle Model

Capacity

*

pints (liters)

RT–34–135

Forward 29.8 (14.1)

Rear 34 (16.1)

RT–40–145

Forward 30.4 (14.4)

Rear 34.4 (16.3)

*

Quantities listed are approximate and include 1 pint (0.5 liter) for each

wheel end and with the drive pinion at 3 degrees.

Table 3, Rockwell Drive Axle Lubricant Capacities,

Tandem Axles

35–02 Axle Breather Checking

The axle housing breather (Fig. 1) must remain

clean. Whenever the axle lubricant level is checked,

check that the axle breather is open. Check more

often under poor operating conditions. If the breather

is plugged, clean or replace it as needed.

35–03 Axle Lubricant Changing

and Magnetic Plug

Cleaning

A regular schedule for changing the axle lubricant in

a particular vehicle and operation can be accurately

determined by analyzing oil samples taken from the

axle at specified intervals or mileages. Lubricant sup-

pliers frequently make their laboratory facilities avail-

able for determining the useful life of their product

under actual service conditions. The final schedule

that is recommended may, for economic reasons, be

correlated with lubricant changes that are governed

by climatic conditions and magnetic plug mainte-

nance. Change lubricant type and viscosity as cli-

matic temperatures demand, regardless of vehicle

mileage or established change schedule.

The normal operating temperature of compounded

lubricants during the summer season is about 160°

to 220°F (71° to 104°C). The chemicals and addi-

tives that give these lubricants increased load-

carrying capacity, oxidize faster at temperatures

above 220°F (104°C), contributing to more rapid lu-

bricant deterioration. For this reason, lubricants of

this type, that operate continuously at high tempera-

tures, must be changed more frequently.

CAUTION

Failure to change the axle lubricant at more fre-

quent intervals, when adverse operating condi-

tions require, could result in axle damage.

Axle Draining and Flushing

1. Remove the plug at the bottom of the housing

and drain the lubricant while the unit is warm.

Allow enough time for all the old lubricant to

drain completely.

Rear Axle35

Business Class Trucks Maintenance Manual, January 199835/2

Loading...

Loading...