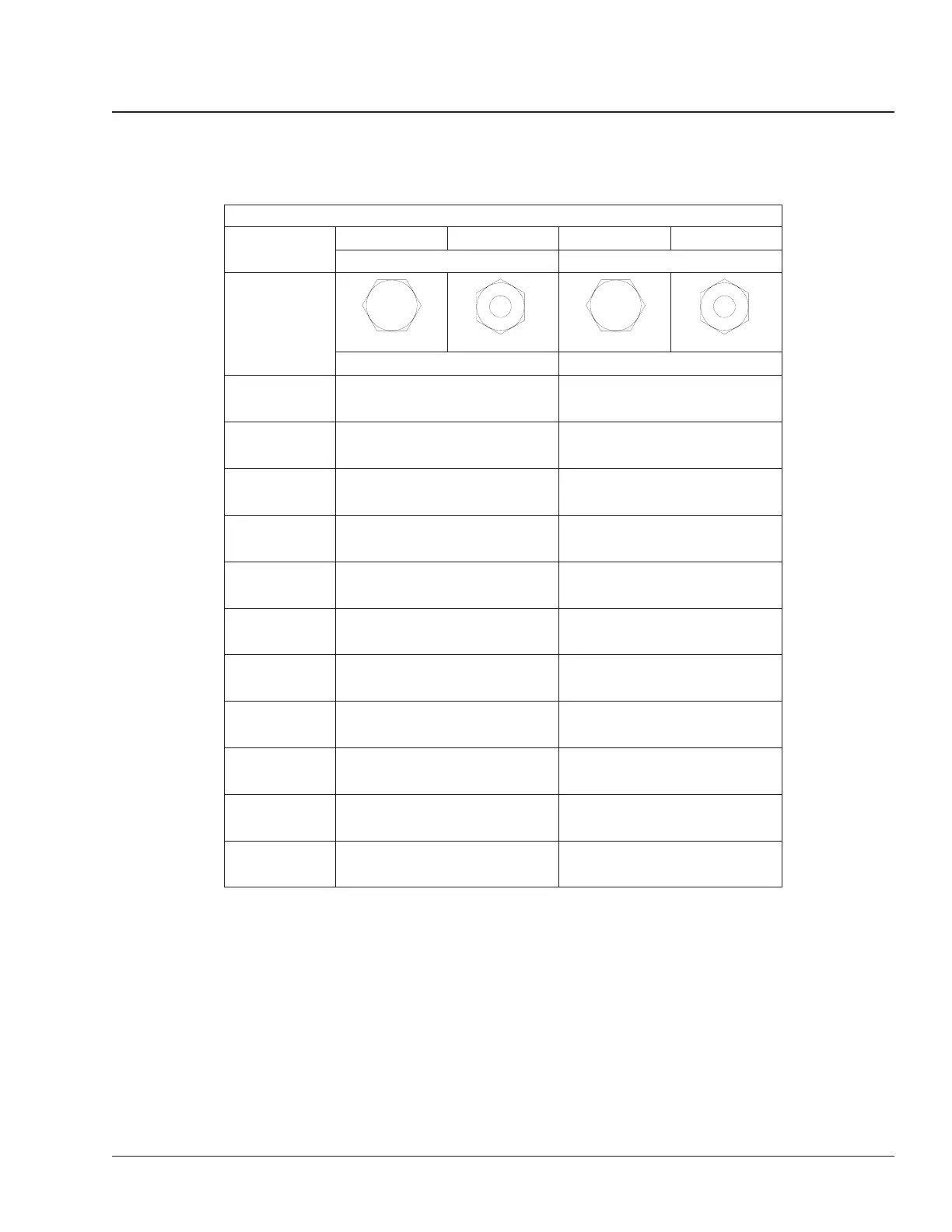

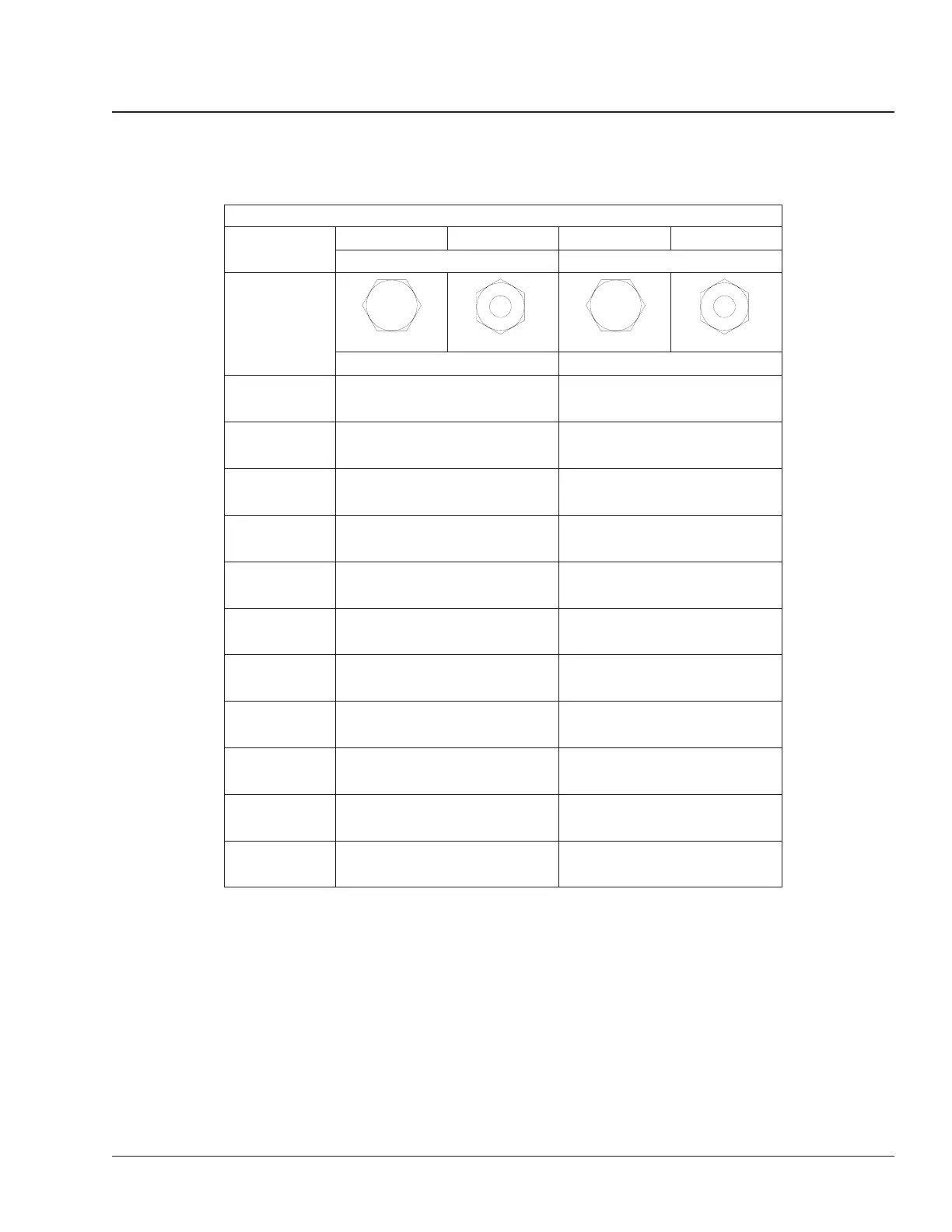

Torque Values for Metric Thread Fasteners with Lubricated

*

or Plated Threads

†

Thread

Diameter–Pitch

Class 8.8 Bolt Class 8 Nut Class 10.9 Bolt Class 10 Nut

Torque: lbf·ft (N·m) Torque: lbf·ft (N·m)

M6

f230010

8.8

f230011

8

f230012

10.9

f230013

10

5 (7) 7 (9)

M8 12 (16) 17 (23)

M8 x 1 13 (18) 18 (24)

M10 24 (33) 34 (46)

M10 x 1.25 27 (37) 38 (52)

M12 42 (57) 60 (81)

M12 x 1.5 43 (58) 62 (84)

M14 66 (89) 95 (129)

M14 x 1.5 72 (98) 103 (140)

M16 103 (140) 148 (201)

M16 x 1.5 110 (149) 157 (213)

M18 147 (199) 203 (275)

M18 x 1.5 165 (224) 229 (310)

M20 208 (282) 288 (390)

M20 x 1.5 213 (313) 320 (434)

M22 283 (384) 392 (531)

M22 x 1.5 315 (427) 431 (584)

M24 360 (488) 498 (675)

M24 x 2 392 (531) 542 (735)

M27 527 (715) 729 (988)

M27 x 2 569 (771) 788 (1068)

M30 715 (969) 990 (1342)

M30 x 2 792 (1074) 1096 (1486)

*

Freightliner recommends that all plated and unplated fasteners be coated with oil before installation.

†

Use these torque values if either the bolt or nut is lubricated or plated (zinc-phosphate conversion-coated,

cadmium-plated, or waxed).

Table 3, Torque Values for Metric Thread Fasteners with Lubricated or Plated

Threads

General Information 00

Torque SSpecifications Tables: 00–03

Business Class Trucks Maintenance Manual, February 2004 00/5

Loading...

Loading...