5. Using a multipurpose, high-temperature grease

that resists water, steam, and alkali, lightly coat

the surfaces of the new O-ring and the dryer

base. Install the O-ring.

6. Thread the desiccant cartridge onto the dryer

base (turn clockwise). When the seal contacts

the base, tighten the cartridge one complete turn

more. Do not overtighten.

42–04 Camshaft Bracket

Bushing Lubricating

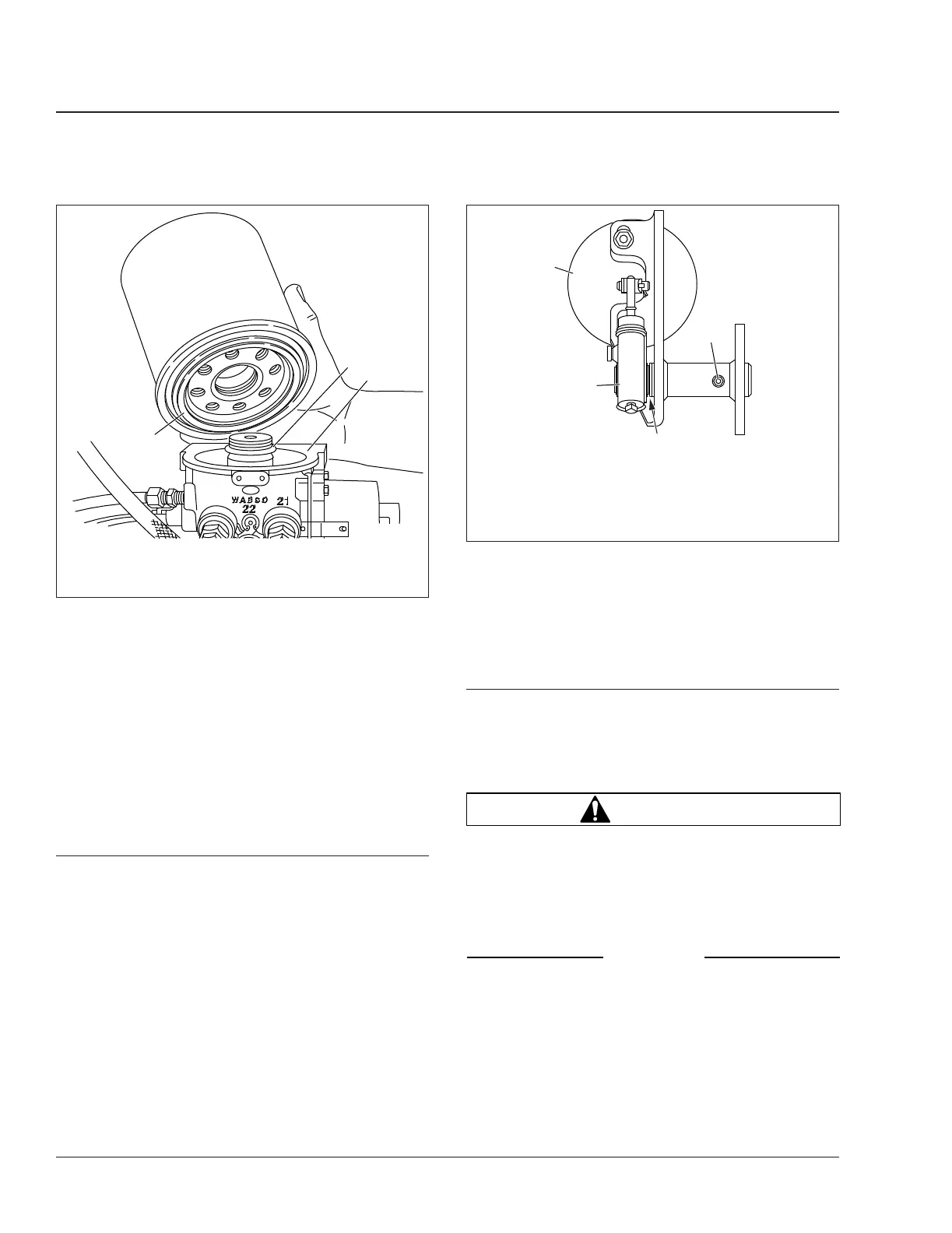

Pump grease into the camshaft bracket bushing until

it appears at the slack adjuster end of the bracket.

See

Fig. 6.

Use an NLGI Grade 1 or Grade 2 multipurpose chas-

sis grease. If grease leaks out from under the cam

head, the camshaft bracket grease seal is worn or

damaged. For grease seal replacement instructions,

see Group 42 of the Recreational Vehicle Chassis

Workshop Manual, or take the vehicle to an autho-

rized Freightliner dealer.

Camshaft brackets without grease fittings are fitted

with special seals and packed with extended-

lubrication-interval chassis grease. Grease them only

when the camshaft is disassembled for servicing.

42–05 Slack Adjuster

Lubricating

IMPORTANT: Perform Maintenance Operation

42–11

before lubricating the slack adjusters.

Automatic slack adjusters must be lubricated periodi-

cally to ensure proper brake operation.

WARNING

Failure to lubricate slack adjusters could lead to

dragging brakes or a brake failure, resulting in

property damage, personal injury, or death.

Haldex

NOTICE

Do not use moly-disulfide-loaded grease or oil.

Both the life and reliability of the slack adjuster

will be reduced if this type of grease is used.

Lubricate a Haldex automatic slack adjuster at the

grease fitting with any extreme-pressure NLGI Grade

1 or Grade 2 grease if the operating temperature is

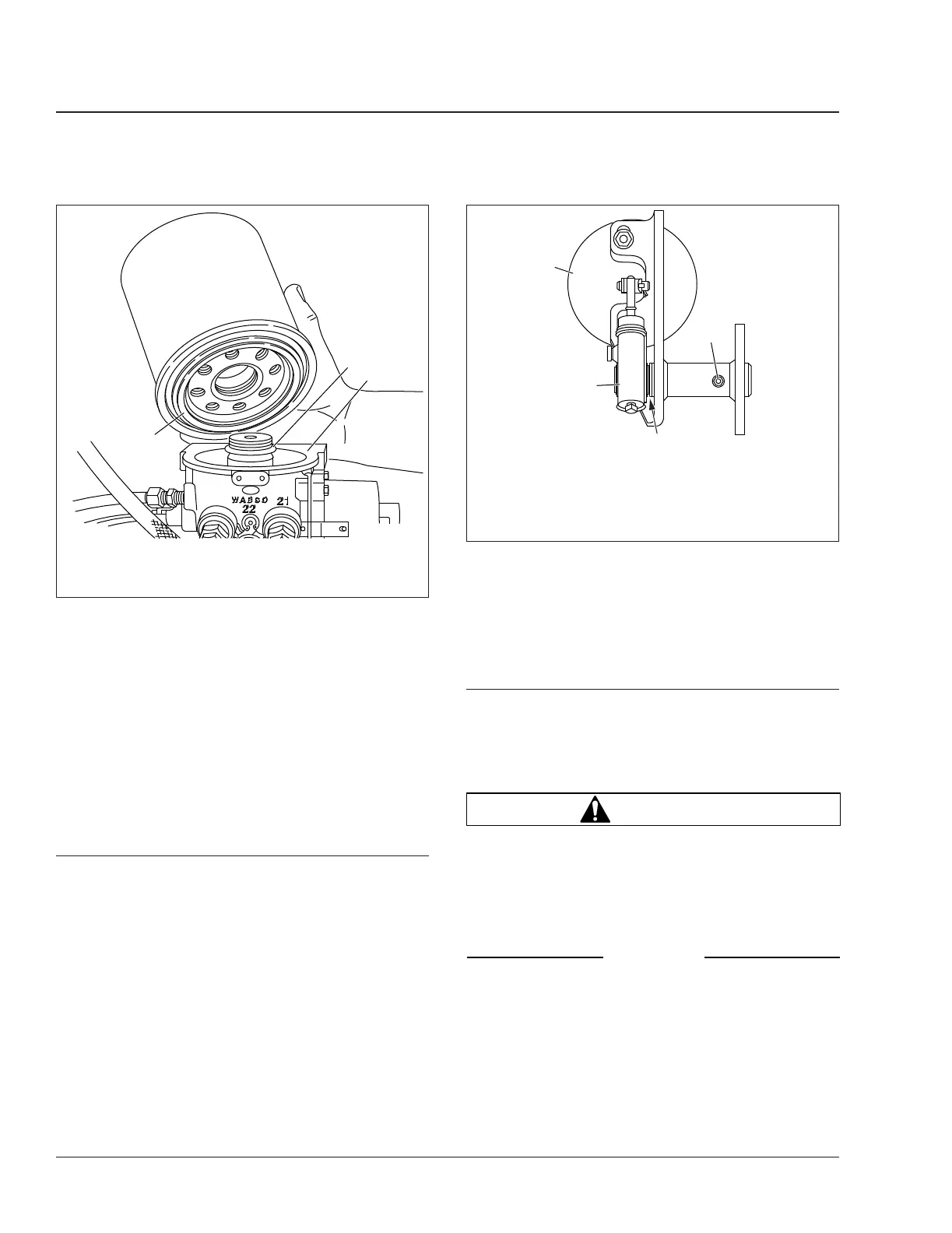

f42129210/07/2016

1

2

3

1. Seal

2. O-Ring

3. Air Dryer Base

Fig. 5, Desiccant Cartridge Replacement

f420011a10/07/2016

1

2

3

A

A. Grease Exit

1. Brake Chamber

2. Slack Adjuster

3. Non-Pressure-Relief Grease Fitting

Fig. 6, Camshaft Bracket Bushing Lubrication

Brakes42

Recreational Vehicle Chassis Maintenance Manual, July 201842/6

Loading...

Loading...