• fasteners

• frame hanger assembly

• QUICK-ALIGN connection

• shock absorbers

• torque rods

• U-beam assembly

WARNING

The pivot bushing and D-pin bushing are critical

components of the V-Ride rear air suspension. If

any components appear damaged or worn, the

component must be replaced. Failure to replace

worn or damaged components can result in the

deformation of parts, loss of clamp force, bolt fail-

ure, loss of axle alignment, loss of vehicle control,

property damage, or personal injury.

There are two types of pivot bushing inspections for

the V-Ride suspension. The pivot bushing can be

visually inspected by looking at the outer rubber

flange(s) of the bushing. If the visual inspection war-

rants, a physical inspection can be conducted in

which disassembly is required.

Pivot Bushing Visual Inspection

To perform a visual inspection of the pivot bushing, it

is not necessary to disassemble the pivot bushing

connection. If the pivot bushing rubber flange(s) are

intact and there are no signs of metal-to-metal con-

tact, the bushing does not require replacement.

• The U-beam assembly is designed with the

pivot bushings centered in each U-beam end

hub. If the pivot bushing is not centered in each

hub, it is an indication that the pivot bushing

could be worn and a pivot bushing physical in-

spection is required.

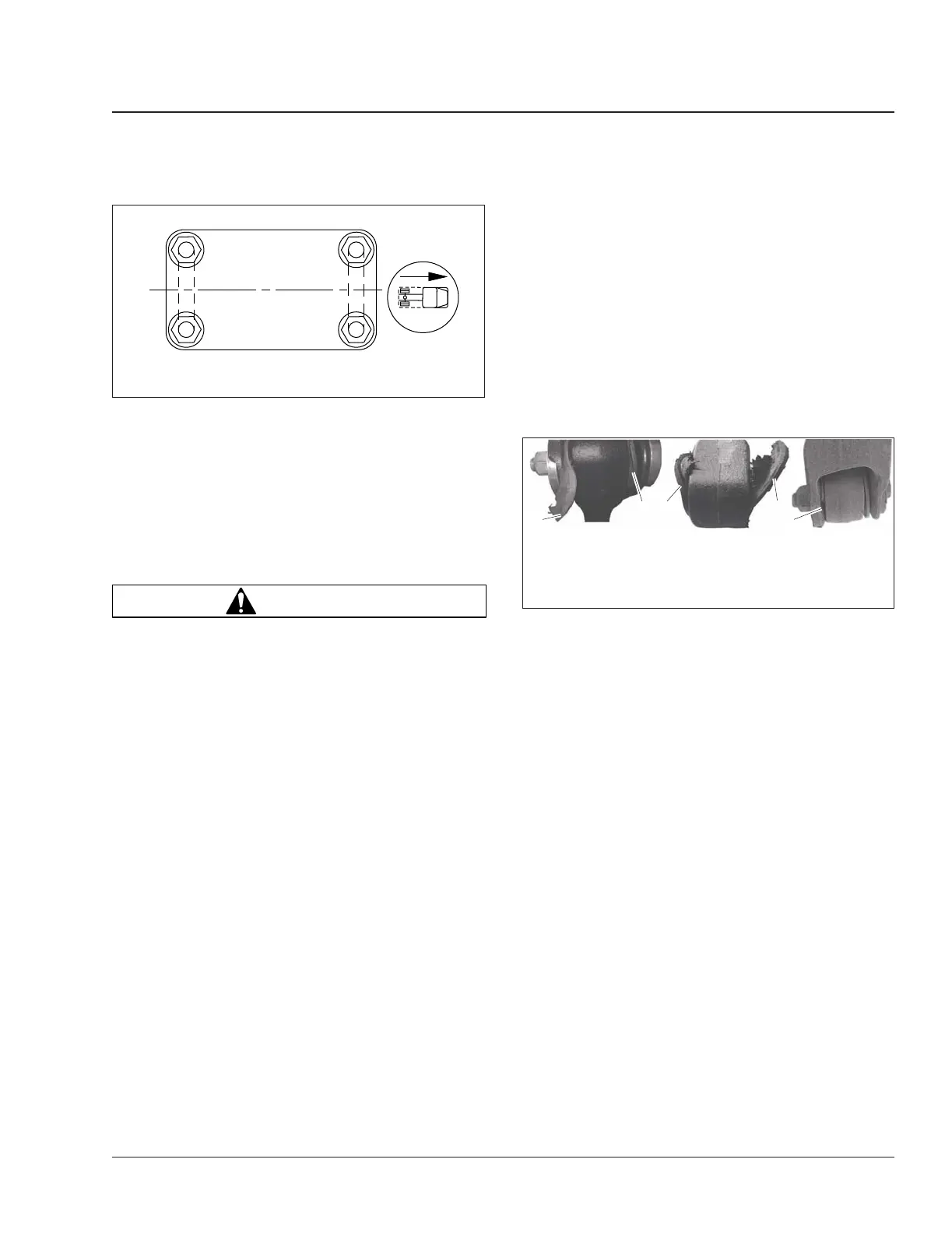

• If the pivot bushing shows signs of torn, sepa-

rated, or disconnected rubber, as shown in

Fig. 7, it could be the result of axle misalign-

ment. If this condition is evident, a pivot bushing

physical inspection is required.

• If the outer rubber flange(s) is missing, or there

are shards of rubber visible, as shown in

Fig. 7,

it could be the result of axle misalignment. If this

condition is evident, the pivot bushing must be

replaced.

Pivot Bushing Physical

Inspection

1. Remove the U-beam assembly. For instructions,

see Section 32.05, Subject 140 in the Recre-

ational Vehicle Chassis Workshop Manual.

2. After removal, inspect the pivot bushing connec-

tions and inner metal areas.

3. No replacement is needed if the pivot bushing

exhibits a tight joint. See

Fig. 8. An imprinted

two-line wear pattern on the bushing inner metal

indicates the pivot bushing is securely clamped

in the frame hanger.

4. Inspect the pivot bushing. See

Fig. 9. Any of the

following items could be the result of axle mis-

alignment or loose fasteners and require replace-

ment of the pivot bushing:

• an elongated or damaged bore

• distorted, separated, or torn rubber

• signs of rust

5. Inspect the inside of the frame hanger legs and

the QUICK-ALIGN collars. If any of the following

f32078310/05/2016

1

23

4

Fig. 6, Tightening Sequence for U-Bolt High Nuts

04/15/2014 f321190

1

2

1

2

3

1. Torn Rubber

2. Disconnected Rubber Flange

3. Missing Rubber Flange

Fig. 7, Inspecting for Torn, Disconnected, or Missing

Rubber Flange

Suspension 32

Recreational Vehicle Chassis Maintenance Manual, June 2015 32/7

Loading...

Loading...